UNDERCARRIAGE GRT9165 SERVICE MANUAL

8-14

Published 10-01-2020 Control # 699-00

charge valve, two hydraulic accumulators, the brake

assemblies, and all the associated hoses and tubing. The

operator depresses the pedal on the tandem brake valve,

located on the cab floor, and the valve modulates the brake

line pressure to the brake assemblies at each wheel. The full

powered brake system supplies a high brake system

pressure with relatively low reactive pedal forces, while

controlling the maximum brake line pressure. The service

brake dual accumulator charge valve regulates flow to the

hydraulic accumulators to provide fully powered

independently separate, primary (front) and secondary

(rear), service brake circuits. Hydraulic pressure is

constantly maintained in the brake circuits by the

accumulators and the charging valve. The brake assemblies

are disc type brakes.

Parking Brake

The parking brake is a hydraulically-controlled, disc-type

brake, located on the front axle. It is spring applied and

hydraulically released. The system consists of a two-position

switch, a three-way solenoid valve, actuator, brake

assembly, and all the associated hardware and tubing. The

selector switch, located on the steering column in the cab, is

used to activate the solenoid valve which controls the park

brake actuator, which applies and releases the park brake.

NOTE: For Description and Maintenance of the tandem

brake valve with treadle pedal, the accumulators,

and the dual accumulator charge valve, refer to

Valves, page 2-21.

Maintenance

Troubleshooting

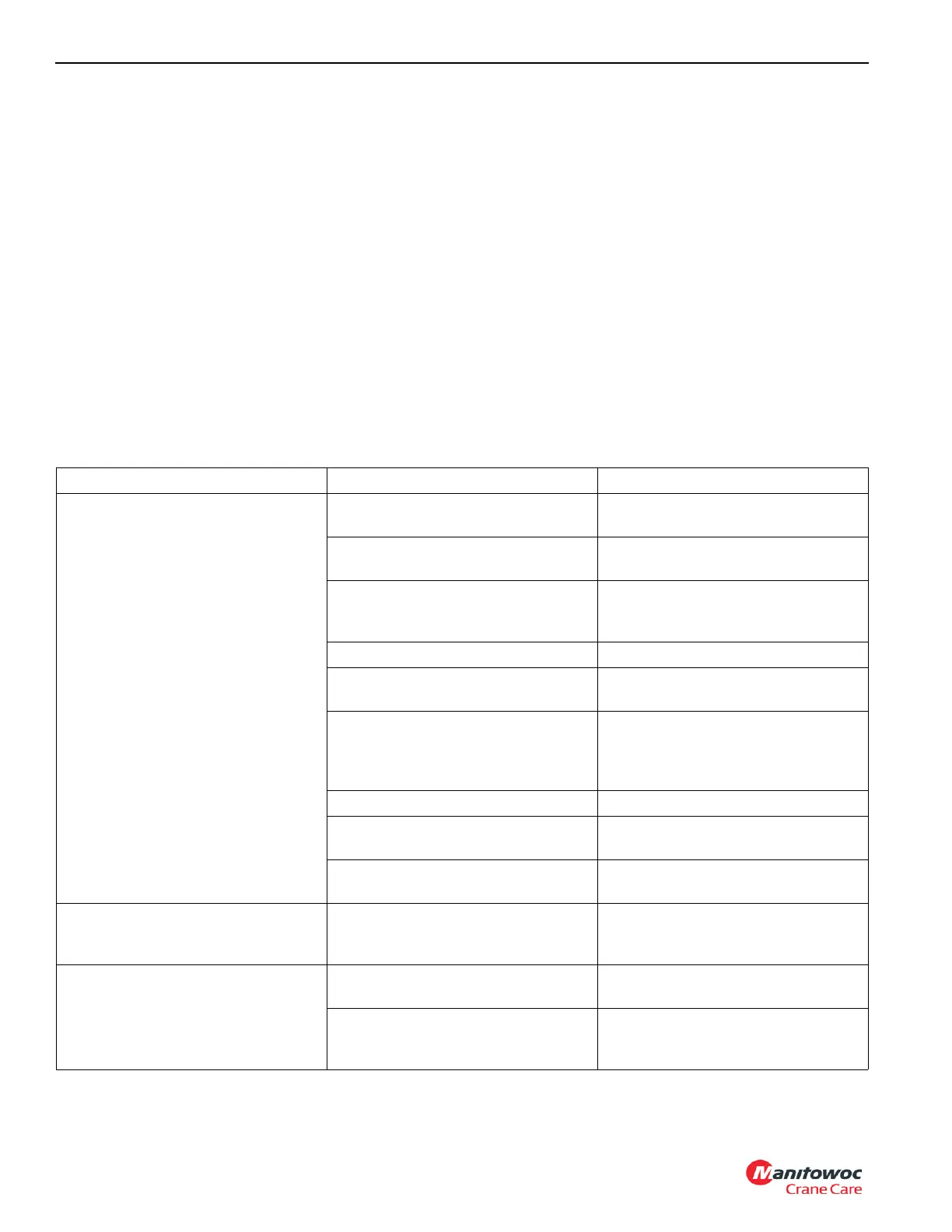

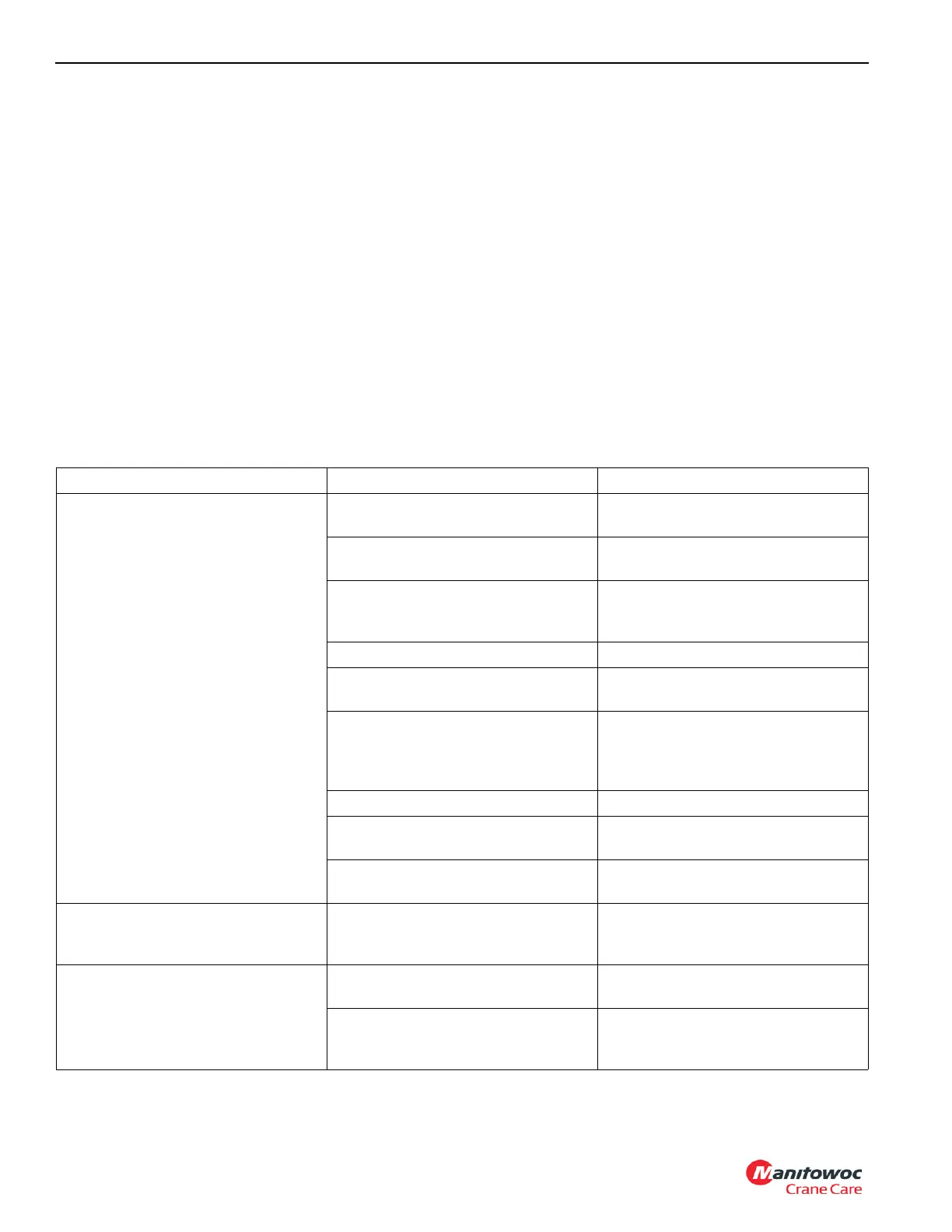

Table 8-3

Symptom Probable Cause Solution

1. Brakes are insufficient. a. Lining thickness less than

0.125 in (3 mm).

a. Replace lining.

b. Restriction or leaks in lines. b. Check all lines for leaks and

restrictions.

c. Low hydraulic oil flow. c. Check the hydraulic oil level in

reservoir and check flow from

the tandem brake valve.

d. Air in brake lines. d. Bleed the brakes.

e. Brake pads/linings are

grease-soaked.

e. Replace pads/linings.

f. Engine not running. f. Start engine. Due to the

operation, the engine must be

running to provide full brake

power.

g. Brake relief valve stuck open. g. Replace the relief valve.

h. Dual accumulator charge

valve not charging

h. Check valve operation and

repair or replace valve.

i. Accumulators not pre-

charged.

i. Check accumulator pre-

charge.

2. Hard brake pedal with engine

running.

a. Pedal travel obstructed. a. Check pedal and ensure it is

unobstructed and moves

properly.

3. Brakes lock up. a. Too much hydraulic pressure. a. Check the flow from the flow

divider.

b. Brake pedal push rod

improperly adjusted, causing

brakes to be always applied.

b. Adjust the push rod linkage so

the brake pedal and push rod

fully return.

Loading...

Loading...