2-55

GRT9165 SERVICE MANUAL HYDRAULIC SYSTEM

Published 10-01-2020 Control # 699-00

b. Back the adjusting screw out until there is 8.0 ±

0.5 mm (0.32 in ±0.02 in) from the end of the

adjusting screw to the top of the jam nut seated

against the valve body (see Cut-Off Screw

Adjustments in Figure 2-25). This adjustment

makes sure the full system pressure cited in

Table 2-3 can be obtained but limit the maximum

cutoff pressure of the pumps.

3. Do the following to make sure the piston pump

differential pressure (stand-by) is correct:

a. With diagnostic quick disconnect (Parker PD240 or

equivalent) still installed in the GP port of the main

directional control valve (1, Figure 2-26), start the

engine.

b. At idle RPM, adjust the piston pump 2 (4,

Figure 2-26) differential setting screw in to increase

or out to decrease so that a gauge reading cited in

Table 2-3 is achieved. It may be necessary to back

out the stand-by adjustment screw for pump 1 if the

pressure cannot be achieved.

c. With the engine still at idle RPM adjust the piston

pump 1 differential setting screw “in” to increase or

“out” to decrease so that a gauge reading cited in is

achieved.

4. Stop the engine. Remove the diagnostic coupler.

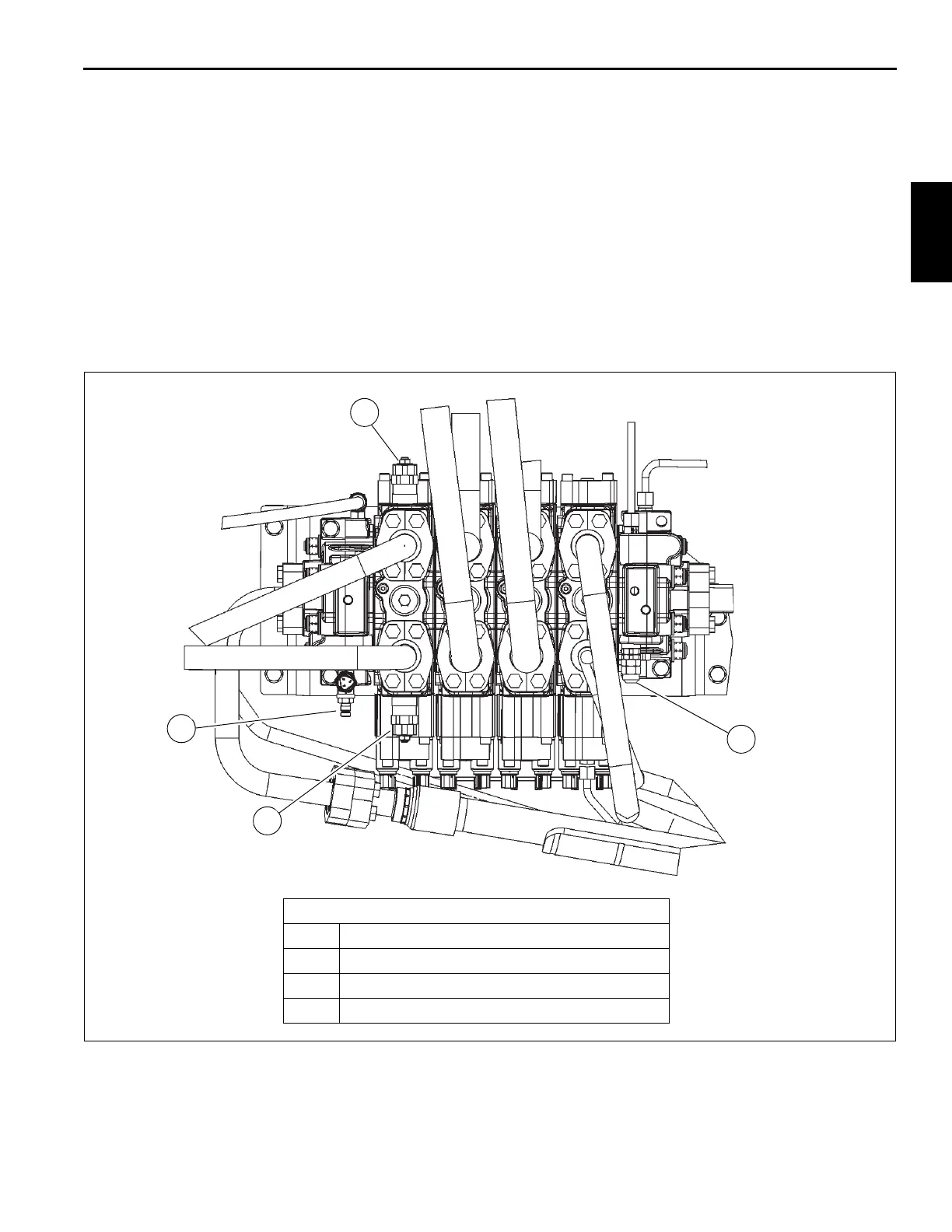

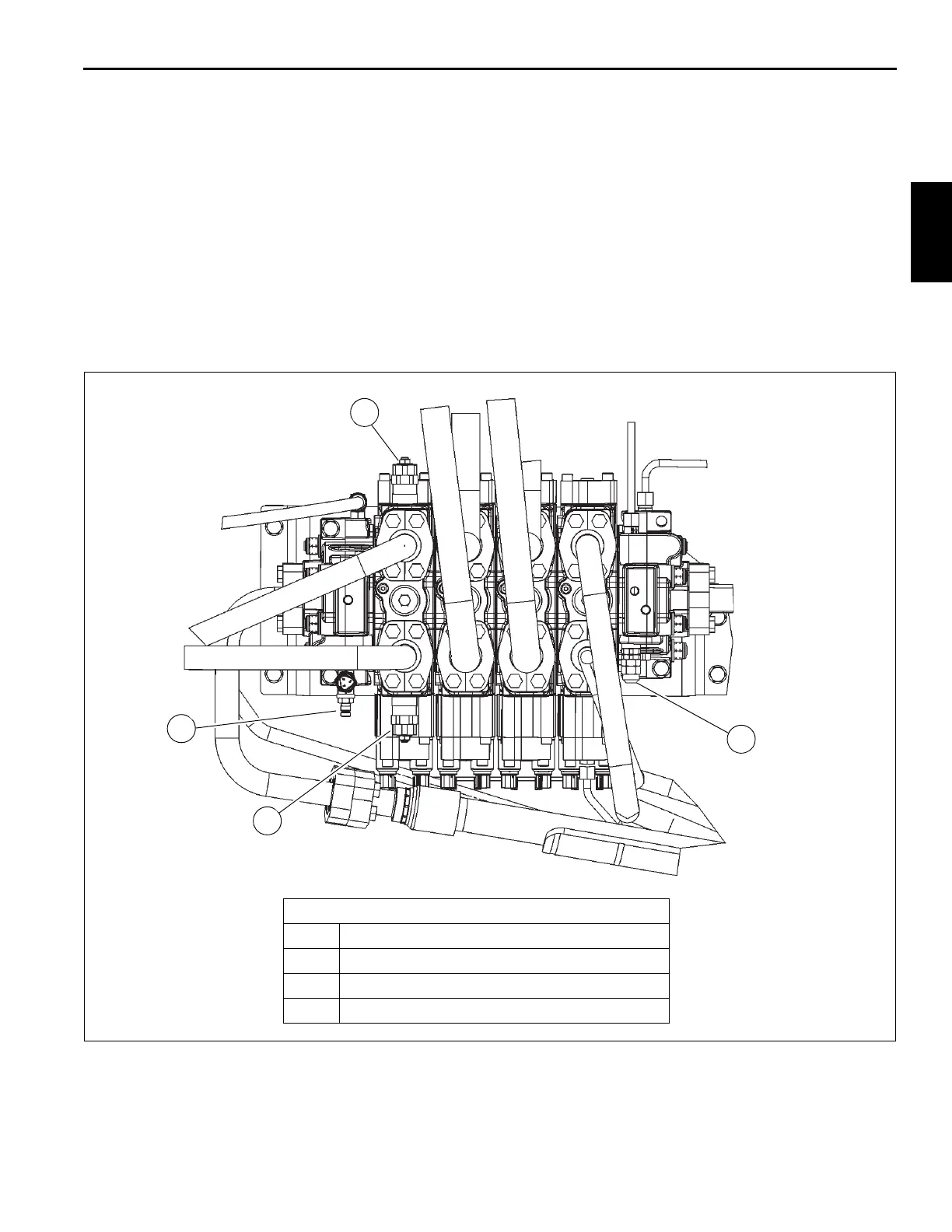

FIGURE 2-24

10136

Main Directional Valve

1 Main Directional Valve GP Diagnostic Port

2 Telescope Extend Relief

3 Telescope Retract Relief

4 LS Relief

2

1

3

4

Loading...

Loading...