11-45

5540F/YB5515 SERVICE MANUAL STRUCTURALS

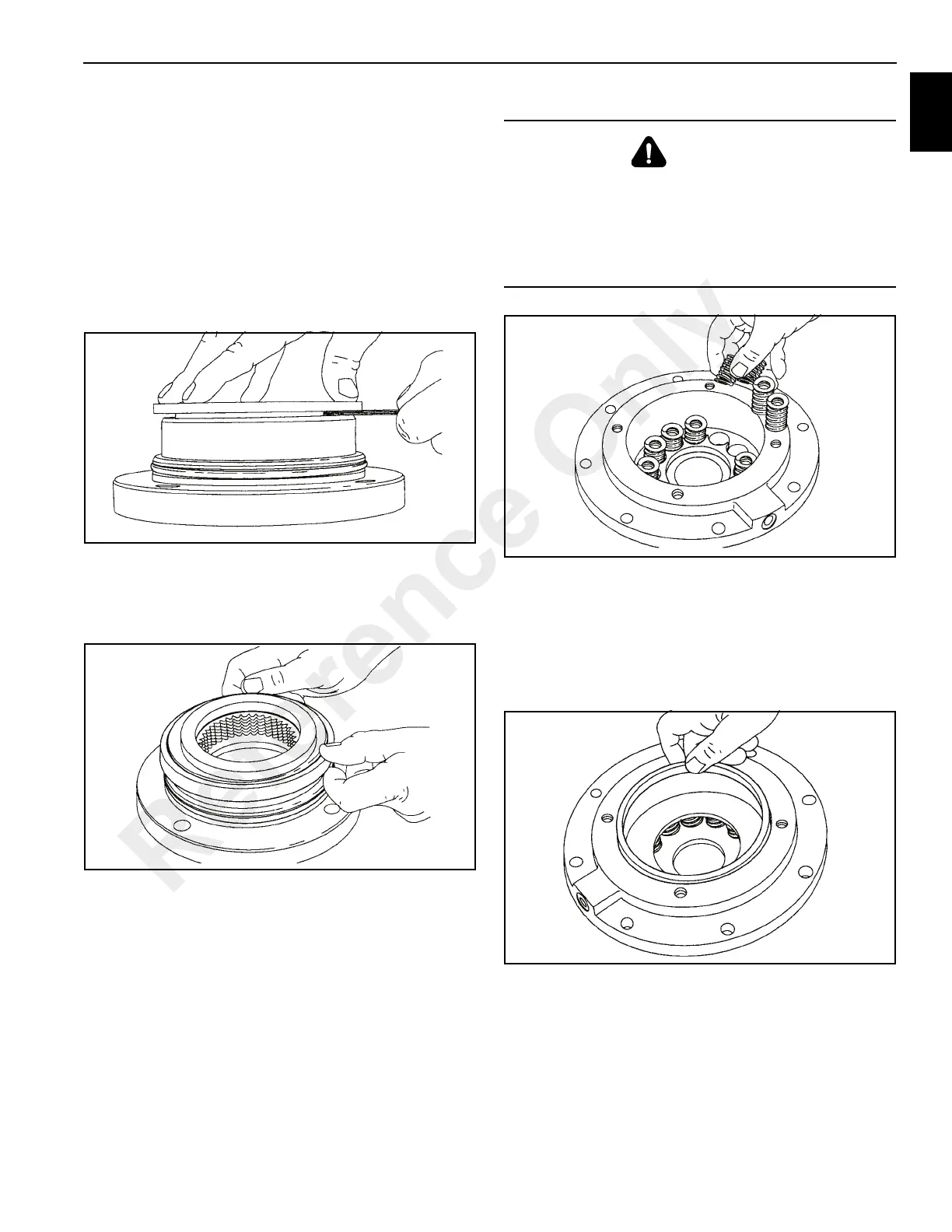

4. To check brake stack height, place a pressure plate on

top of brake spacer. Hold pressure plate down firmly by

hand and measure the clearance in three places

between the motor support and the pressure plate

(Figure 11-104). Average gap must measure between

0.153 in. (4 mm) maximum and 0.80 in. (2 mm)

minimum. If the gap exceeds the maximum limit, there

are too many brake discs in the stack-up, or the brake

discs are distorted. If the gap is less than the minimum,

there are too few discs in the stack-up, or the discs are

worn out. If the stack-up height is correct, remove

pressure plate and continue with assembly.

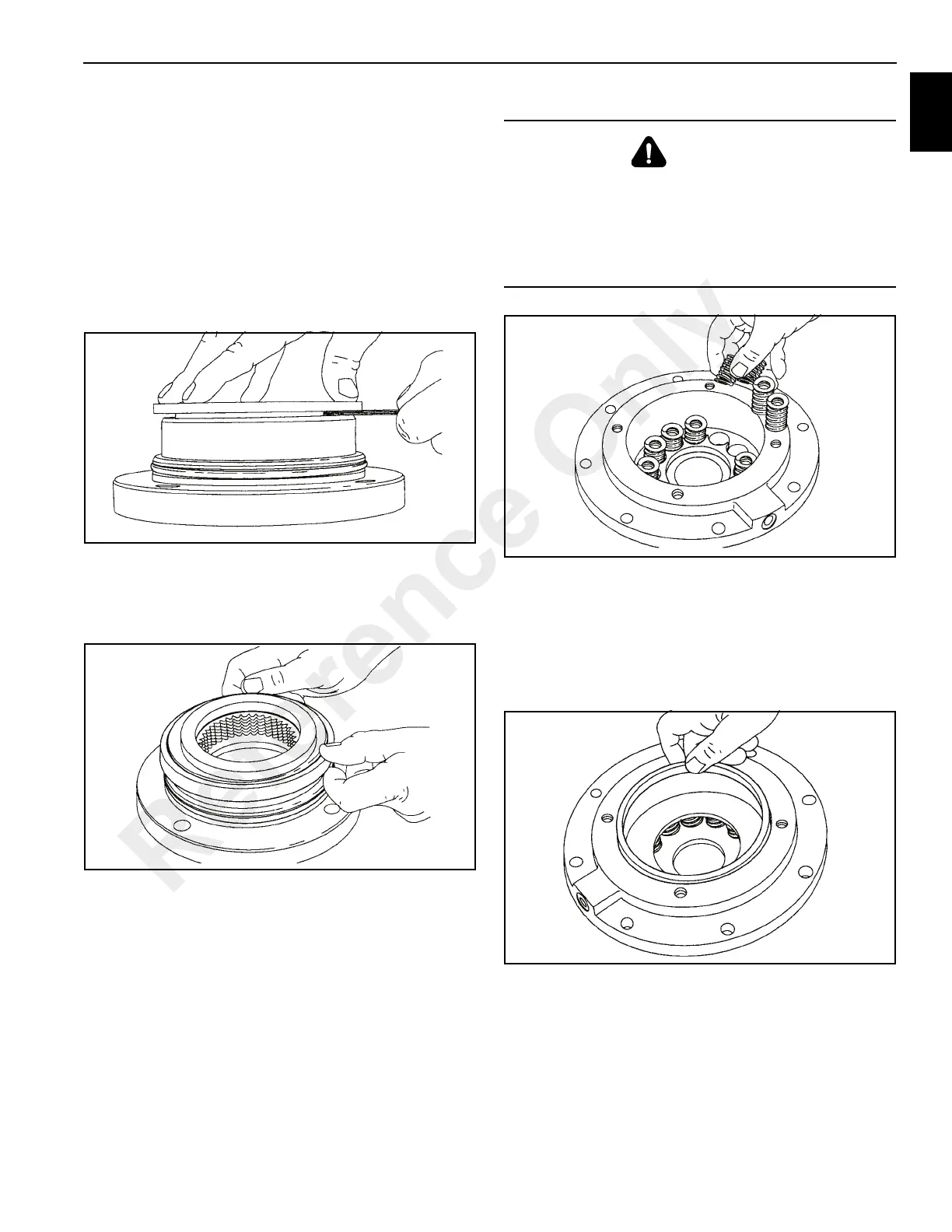

5. Lubricate the brake piston seal and motor support

sealing surface with petroleum jelly or hydraulic oil.

Insert a new piston seal to the motor support with the lip

seal down (Figure 11-105).

6. Install the spring spacer and then the brake springs

(Figure 11-106).

7. Install the pressure plate into the brake cylinder followed

by the piston backup ring (Figure 11-107). The close

fitting piston backup ring may be depressed slightly to

one side to lodge the backup ring in the brake cylinder

bore.Temporarily hold the pressure plate and springs in

place while lowering the brake cylinder over the motor

support.

8. Apply petroleum jelly to the entire sealing surface of the

brake cylinder and to the piston seal. Install the brake

cylinder over the motor support (Figure 11-108) being

careful to avoid damaging the piston seal or motor

support o-ring. A press may be necessary to avoid

cocking the brake cylinder during installation.

WARNING

Always use the molded spring spacer with the brake

cylinder. The brake springs must be properly positioned

by the spring spacer. Failure to install the spring spacer

may allow the springs to contact each other and become

damaged. This could result in loss of load control,

property damage, injury or death.

Reference Only

Loading...

Loading...