TESTING

Maytag Chopper Dishwashers

n

3-3

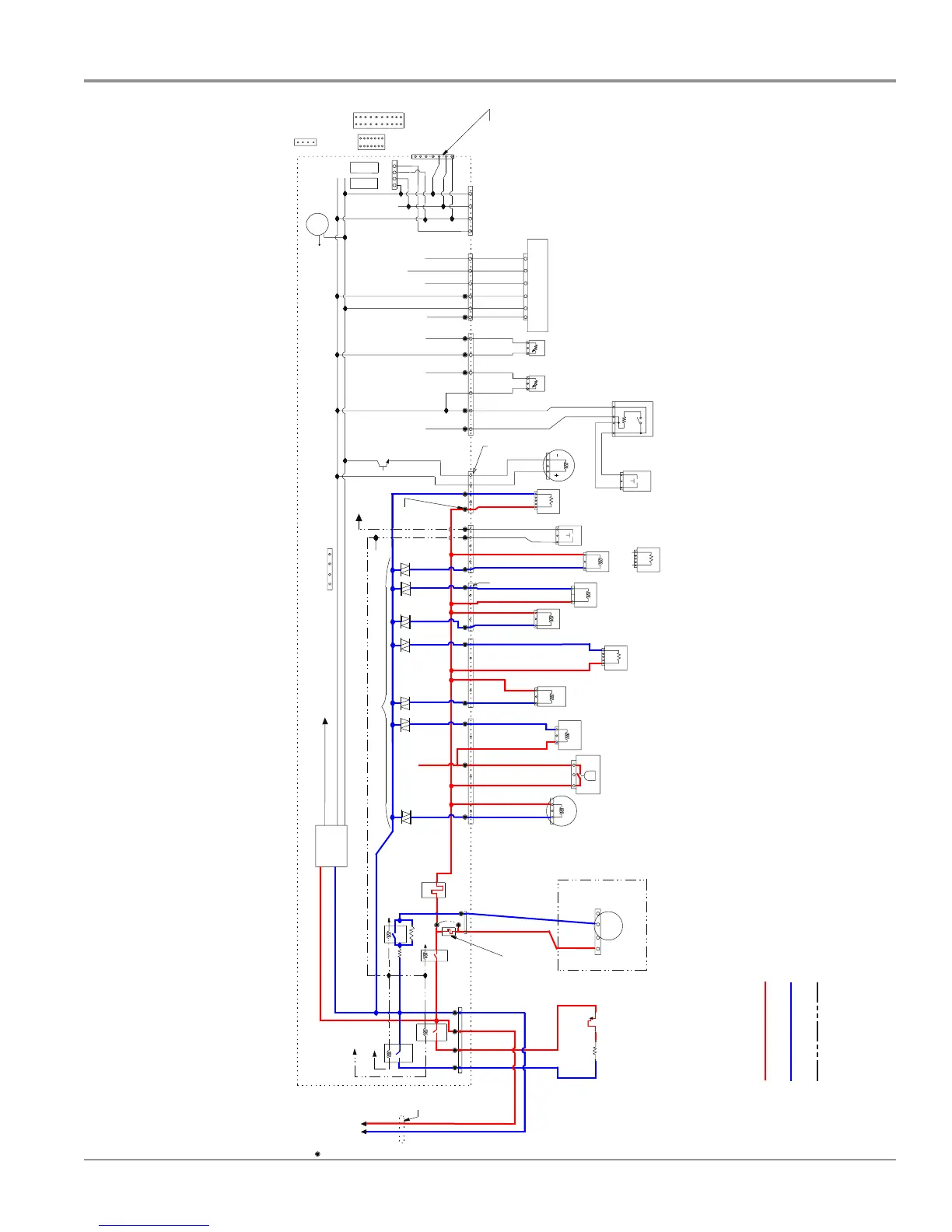

Wiring Diagram

Schemac shown with door switch and all other normally open contacts open.

* Denotes energy ecient components. Do not substute.

For Service Technician Use Only

L1

N

13V

2

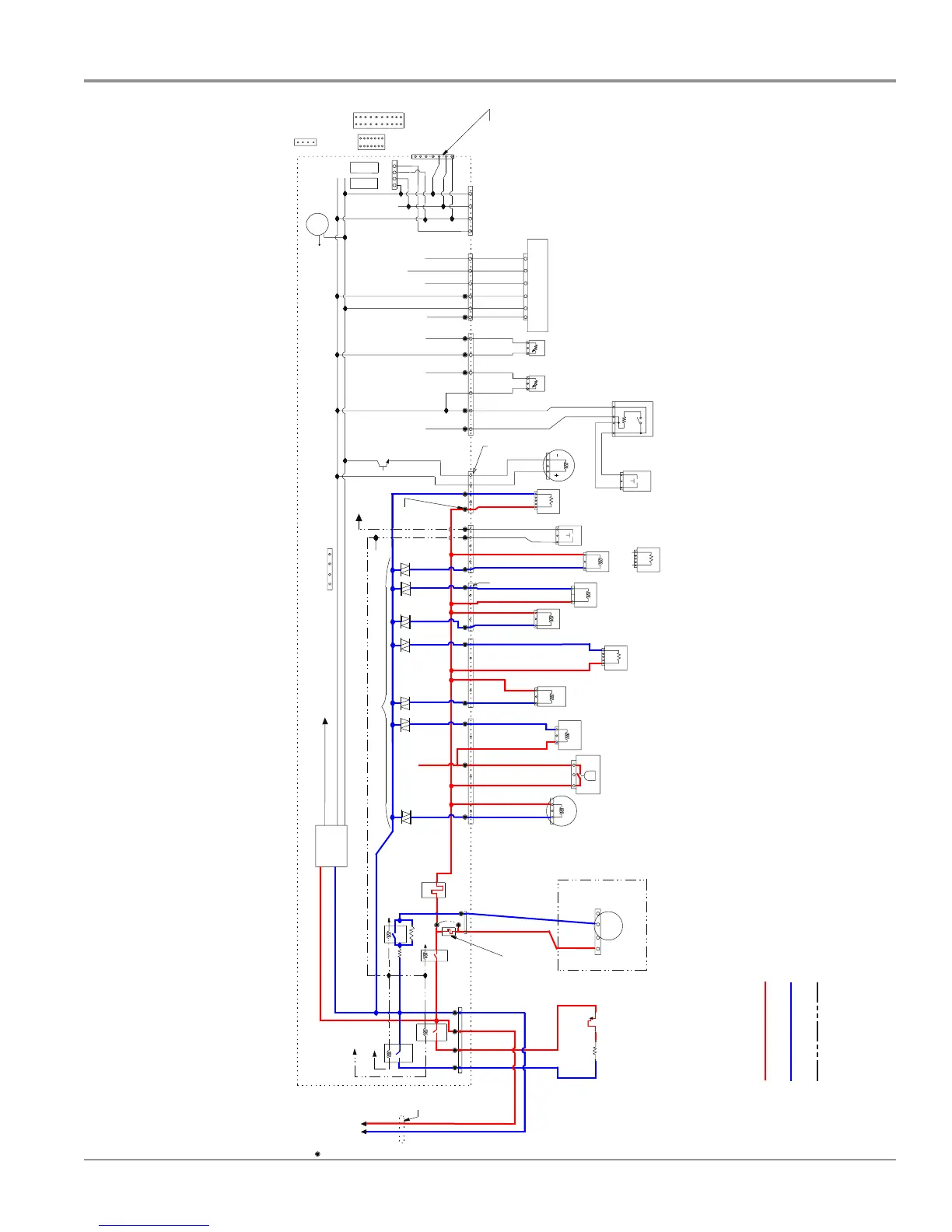

Wiring Diagram

Schematic shown with door switch and all other normallyopen contacts open.

*Denotes energyefficient components. Do not substitute.

Line

WH

BK

BK

Line

WH

K1

K3

P4

N

321

1

3

3

3

3

1

1

1

3

1

3

1

3

1

3

1

31

3

12

1

3

12

34

3

1

3

12

4

5

6

123

4

13V

1

3

2

4

5

6

7

Micro Pin

4

3

1

3

1

5

1

Most used test points on

PC board for multimeter

checks

Electronic Control* CCU1 PC Board

7

¹⁄₂

" x 3

³⁄₁₆

" (190.28 mm x 81.01 mm)

2-sided FR4

Micro Pin

Micro Pin

N

HTR-N

Relay

HTR-L

Relay

Ferrite

(1 Loop)

BU/WH

P4-4

P4-3BU/RD

BK

P4-2

WH

P4-1

Thermostat

(Hi-Limit)

BU/R

BU/R

N.C.

Heater

Element

A-Sync Wash

Motor Pump

with Chopper

L1

L1

This option

no fuse,

jumper only

P5-2

LBU

LBU

P5-1

K2

Pilot

Relay

Fuse

F8

P5

W2

Fuse

F9

Micro Pin

Optional

Sense

K4 Motor Relay

Motor Sense Circuit

is different for high

versus low power motors

Return Line 13-volt relays coils goes through door switch

Power Supply

Level 1-3 W

Level 2-4.4 W

Level 3-7.4 W

13V

(+8V)

VCC

(N)

REF

(-5V)

Load (Current) Sense for Drain, Vent, and all other Tr iac loads on Pilot

AC Input

Overfill/Leak Detection

(and Pilot Relay Detection)

P6

P6-1BR

BR P6-3

P6-4

BR

BR

BRBR

P6-6

BR P6-7

BR P6-9

Drain

Motor

Overfill

(Float)

Switch

Fill Valve*

Softener

Regen Valve

(not all models)

TurboZone

Wax Motor

(not all models)

(Spare)

Future

Dispenser

Solenoid

OR

Dispenser

Wax Motor

(Spare)

Future

Door

Switch

Vent Wax Motor

(not all models)

Fan Motor

(not all models)

Flow Meter

Optional

(not many models)

39K

Softener

Salt Sensor

(Closed when empty)

(not all models)

(Spare)

Future

(Spare)

Future

O.W.I.*

(NTC, Foam, and Turbidity Sensor)

Black strip on connector

Red strip on connector

P7-1BU

BU

P7-3

P7-4

BU

BU

P7-6

P8-1

RD

RD

RD

RD

P8-3

P8-4

P8-6

V

V

V

V P9-1

P9-3

P9-5

P9-6

BR

BR

BR

BR

P10-1

P10-3

P10-4

P10-5

RD

RD

RD

RD

RD

RD

P11-1

P11-2

P11-3

P11-4

P11-5

P11-6

YL

YL

YL

YL

YL

YL

P12-1

P12-2

P12-3

P12-4

P12-5

P12-6

P7

P8

P9

P10

P11 P12 P13

Door Open Detection

13V

Pilot L1

Test Pad

for all

Triac

Loads

Fan Load

(Current)

Sense

Analog

Input

Analog

Input

Digital

Input

NTC

Input

Opt

Sig

Foam

Drive

Turbo

Drive

13V

VCC

Wide

Data

REF

Wide Data

VCC

P3

(Wide Out)

Temporary connection

port for development tools

(and future service tools)

P1A and P1B User Interface

Connector Options

Mechanical Push-Button

Boards and Active Overlays

20-Pin

LED

Displa

ys

14-Pin

P1A

P1B

Capacitive

Touch

Keyboards

4-Pin

P1-VCC

P4-REF

Beeper

P2

In-Factory Programming Port

(on top surface of PCB)

(depopulate in production; use pads)

P1C

1

2

3

4

Loading...

Loading...