TESTING

Maytag Chopper Dishwashers

n

3-9

For Service Technician Use Only

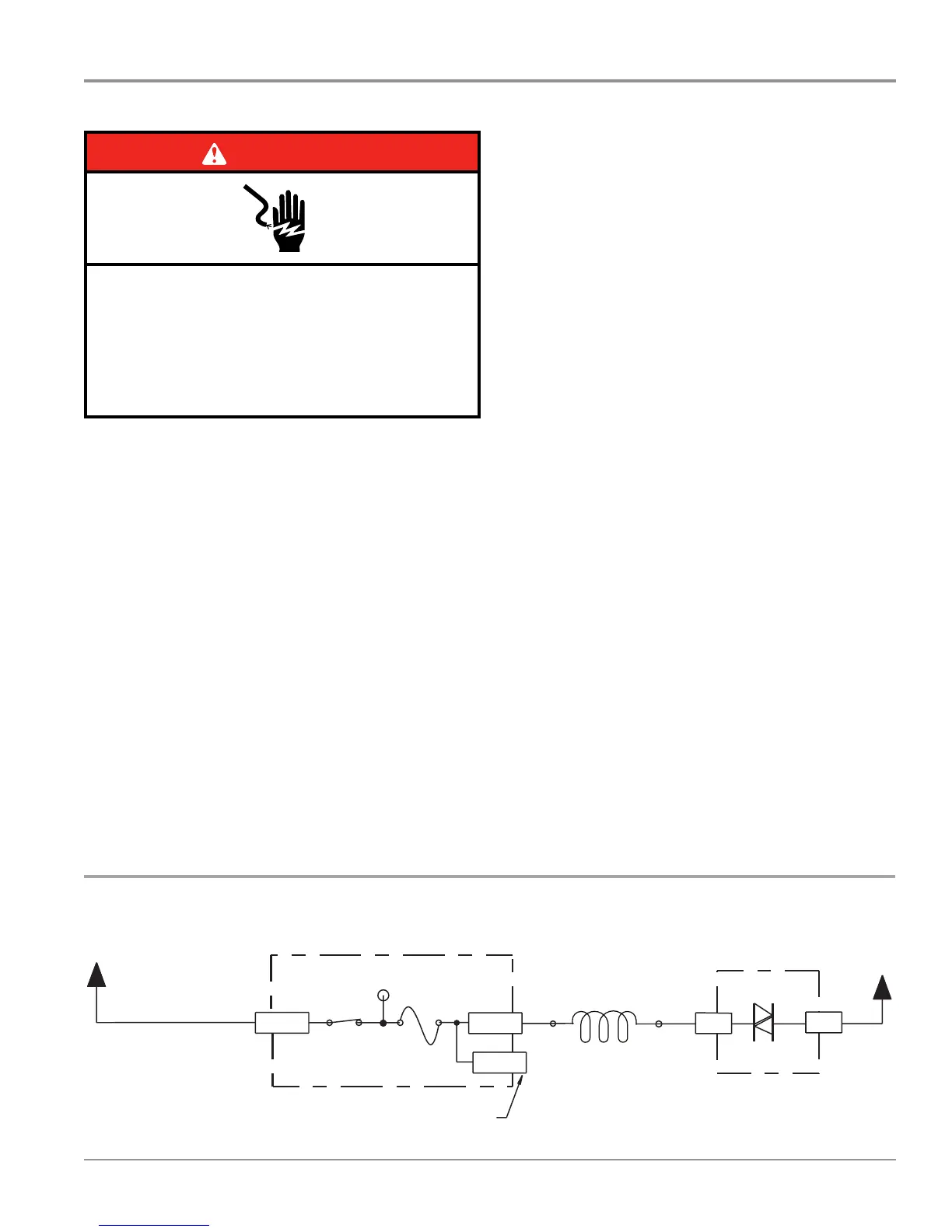

Dispenser Circuit

This test will check the wiring to the dispenser and the

dispenser solenoid or wax motor itself. The following items

are part of the dispenser circuit.

n Harness/Connecon

n Dispenser Solenoid/Wax Motor

n Control Board

Test Procedure

1. Check for obstrucons or mechanical binding prevenng

the dispenser lid from opening. Repair or replace as

necessary.

2. Are all the loads controlled by TRIACs not working?

¾ YES – check for open door switch, TRIAC fuse, or pilot

relay.

¾ NO – just the Dispenser. Go to step 3.

3. Unplug dishwasher or disconnect power.

Strip Circuit – Dispenser

4. Remove outer door panel to access dispenser and r

emove

toe and access panels to access control board.

5. Unplug connector P9 from control board.

6. Check the dispenser solenoid or wax motor (depending

on model) and harness—using an ohmmeter, measure the

resistance between P9-1 and P9-3.

Solenoid:

¾ If the resistance is between 260-300 ohms, the

solenoid valve and harness are good. Go to step 7.

¾ If outside the range, replace the dispenser solenoid.

¾ If an open circuit is detected, check connecons and

harness connuity between control and dispenser. If

good, replace the dispenser solenoid.

Wax Motor:

¾ If the resistance is between 1.4-3.0K ohms, the wax

motor and harness are good. Go to step 7.

¾ If outside the range, replace the dispenser wax motor.

¾ If an open circuit is detected, check connecons and

harness connuity between control and dispenser. If

good, replace the dispenser wax motor.

7. Reconnect P9 to control board.

8. Set voltmeter to AC and connect leads to test-pads P10-

1 & P9-1 on the control board. Plug in dishwasher or

reconnect power.

9. Start the Diagnosc Cycle and at the proper interval

measure for AC out of the control between P10-1 to P9-1.

(Refer to the Dispenser Strip Circuit below.)

IMPORTANT: The Dispenser Solenoid or Wax Motor must

be connected to the control board to measure voltage

accurately!!!

¾ If no AC voltage is measured, replace the control board

and retest.

¾ If 120 VAC is measured and dispenser motor/solenoid

is energized, go to step 10.

10. Unplug dishwasher or disconnect power.

11. Reassemble all parts and panels.

12. Plug in dishwasher or reconnect power and run Diagnosc

Cycle to verify repair.

5

Drain

Dispenser (Detergent and Rinse Aid)

Diverter Valve

Water Softener

Controlled Lower Spray Arm (on some models)

Drying

For Heated Dry, heater is also running. See “Heater” circuit under “Water Heating/Heat Dry and Water Sensing with O.W.I. Sensor (Water/Air/Soil/Temperature)”.

L1

BK

P4-2

P6-3

P10-1

P6-1

P4-1

BR BR WH

N

Use top hole of jumper

W2 as test point for F9.

N.O.

K2

Pilot L1 Relay

(Also see Door

Switch Circuit)

Fuse

F9

Electronic Control

Electronic Control

No test pad on P6-3.

Recommend using test pad on P10-1.

Pin 1

Pin 3

Drain Motor

15

Ω

- 25

Ω

120V, 60 Hz, 45W

Triac

N

WH

P4-1

Pin 1

Pin 3

Electronic Control

Use top hole of jumper

W2 as test point for F9.

N.O.

K2

Pilot L1 Relay

(also see Door

Switch Circuit)

P4-2 P9-3 P9-1

BK

L1

V

V

P10-1

Fuse

F9

Dispenser Wax Motor

1.4K

Ω

- 2.8K

Ω

120V, 60 Hz, 10W

Pin 1

Pin 5

Test pad on P9-3 might crowd P9-1.

Recommend using test pad on P10-1.

Dispenser Solenoid

260

Ω

- 300

Ω

120V, 60 Hz, 17W

Electronic Control

Triac

Electronic Control

Sensor

Input

Switch closes momentarily

and then reopens as the diverter

reaches each potential diverter position.

Diverter

Position

Switch

Electronic Control

No test pad on P11-3.

Recommend using test pad on P11-2.

P11-4

P11-3

P11-2

5V

N.O.

Diverter Sensor

Diverter Motor

L1

BK

P4-2 P7-4

P10-1

P7-6

P4-1

N

WHBU

BU

Pin 3

Pin 1

Use top hole of jumper

W2 as test point for F9.

N.O.

K2

Pilot L1 Relay

(Also see Door

Switch Circuit)

Fuse

F9

Electronic Control

No test pad on P7-4.

Recommend using test pad on P10-1.

Electronic

Control

Triac

Dispenser Valve Motor

1,300

Ω

- 1,600

Ω

120V, 60 Hz, 3W

L1

Regeneration Valve

BK

P4-2

P7-3

P10-1

P7-1

P4-1

N

WH

VV

Use top hole of jumper

W2 as test point for F9.

K2

Pilot L1 Relay

(Also see Door

Switch Circuit)

Fuse

F9

Pin 1

Pin 3

N.O.

Electronic Control

Electronic

Control

Triac

No test pad on P7-3.

Recommend usin

ad on P10-1.

Regeneration Valve

890

Ω

- 1,090

Ω

120V, 60 Hz, 6W

Electronic Control

P11-2

P11-1

RD

RD

(RD)

N.O.

N.O.

5V

(Optional Flowmeter)

Sensor

Input

(Closed when salt low)

Salt Level Reed Switch

39 K

Ω

Salt Level Sensing

Pin 1

Pin 1

Pin 4

Pin 2

Pin 3

Pin 3

Electronic

Control

(RD)

RD

RD

RD

RD

RD

WH

Lower Spray Arm Motor

K2

Pilot L1 Relay

(also see Door

Switch Circuit)

Electronic Control

No test pad on P8-3. Recommend using

test pad on P10-1.

(BU stripe

on plug)

(BU stripe

on plug)

(BU stripe

on plug)

Spray Arm Motor

1,890 - 2,310

Ω

each coil

120 V, 60 Hz, 6 Watts

Controlled Lower Spray Arm Sensor

P1A-17

P1A-19

P1A-20

RD

L1

BK

P4-2 P10-1

P10-3

P4-1

BR BR WH

N

Use top hole of jumper

W2 as test point for F9.

N.O.

K2

Pilot L1 Relay

(Also see Door

Switch Circuit)

Fuse

F9

Electronic Control

Electronic Control

(Red stripe

on plug)

(Red stripe

on plug)

Pin 5

Pin 1

Vent Wax Motor

600

Ω

- 1,800

Ω

120V, 60 Hz, 6W

Electronic Control

Electronic Control

(Red stripe

on plug)

(Red stripe

on plug)

P10-5

P10-4

P11-5

DC Ref

BR

BR

Pin 1 Pin 3

Fan Motor

31K

Ω

- 41K

Ω

5 VDC, 1W

Must measure resistance

with correct polarity and

disconnected from controls.

No test pad on P10-4.

Recommend using test pad on P11-5.

5V

_

+

Vent

Fan

DANGER

Electrical Shock Hazard

Only authorized technicians should perform

diagnostic voltage measurements.

After performing voltage measurements,

disconnect power before servicing.

Failure to follow these instructions can result in

death or electrical shock.

Dispenser Wax Motor

1.4KW - 3.0KW

120V, 60Hz, 10W

Loading...

Loading...