TESTING

Maytag Chopper Dishwashers

n

3-15

Strip Circuit – Vent Fan

For Service Technician Use Only

DANGER

Electrical Shock Hazard

Only authorized technicians should perform

diagnostic voltage measurements.

After performing voltage measurements,

disconnect power before servicing.

Failure to follow these instructions can result in

death or electrical shock.

Vent Fan (not on all models)

This test will check the wiring to the vent and the vent fan

itself. The following items are part of the vent fan circuit.

n Harness/Connecon

n Vent Fan

n Control Board

NOTES:

Only dishwashers with the Heated Dry opon have a vent and

fan. If moisture is detected between outer and inner door

panels or on cabinets around air inlet located on side of door

panel, check that the vent damper is closing properly using the

Service Diagnosc Cycle.

Also verify that wax motor seal and vent bezel seal are not

pinched or missing. Verify there are no leaks around the vent

bezel seal allowing moisture past the bezel and into the door

panel area.

Test Procedure

1. Check the vent fan and electrical connecons by

performing the Service Diagnosc Cycle. The following

steps assume that this step was unsuccessful.

2. Unplug dishwasher or disconnect power.

3. Remove outer door panel to access control board.

4. Unplug connector P10 from control board.

5. Check the resistance of the fan motor coil. With a

ohmmeter, connect the black lead to P10-5 and the red

lead to P10-4. IMPORTANT: Note measurement polarity.

¾ If the resistance is between 31-41 k-ohms, the fan

motor and harness are good. Go to step 6.

¾ If outside the range, replace the fan motor.

¾ If an open circuit is detected, check connecons and

harness connuity between control and fan motor. If

good, replace the fan motor assembly.

6. Reconnect P10 to control board.

7. With a voltmeter set to DC, connect the black lead to

P10-6 and the red lead to P10-5. IMPORTANT: Note

measurement polarity.

8. Plug in dishwasher or reconnect power.

9. Check for DC voltage from the Control. Start the

Diagnosc Cycle and at the proper interval measure for

+5V DC out of the control between P10 pins 4 & 5.

¾ If +5V DC is measured and fan is running, go to step 10.

¾ If no voltage is measured, replace the control board

and retest.

10. Unplug dishwasher or disconnect power.

11. Reassemble all parts and panels.

12. Plug in dishwasher or reconnect power.

6

Drying

For Heated Dry, heater is also running. See “Heater” circuit under “Wash/Rinse” and “Water Heating/Heat Dry and Water Sensing with O.W.I. Sensor (Water/Air/

Soil/Temperature)” circuits.

Service Diagnostics with Error Codes

Entry sequence: Press START/RESUME to wake up the control panel. Press

any 3 keys in the sequence 1-2-3-1-2-3-1-2-3 with no more than 1 second

between key presses.

NOTE: Some models have replaced the “Clean” LED with “Completed.”

NOTE: Once error codes are extracted Refer to “Service Error Codes Table” to

diagnose and correctly resolve root cause condition.

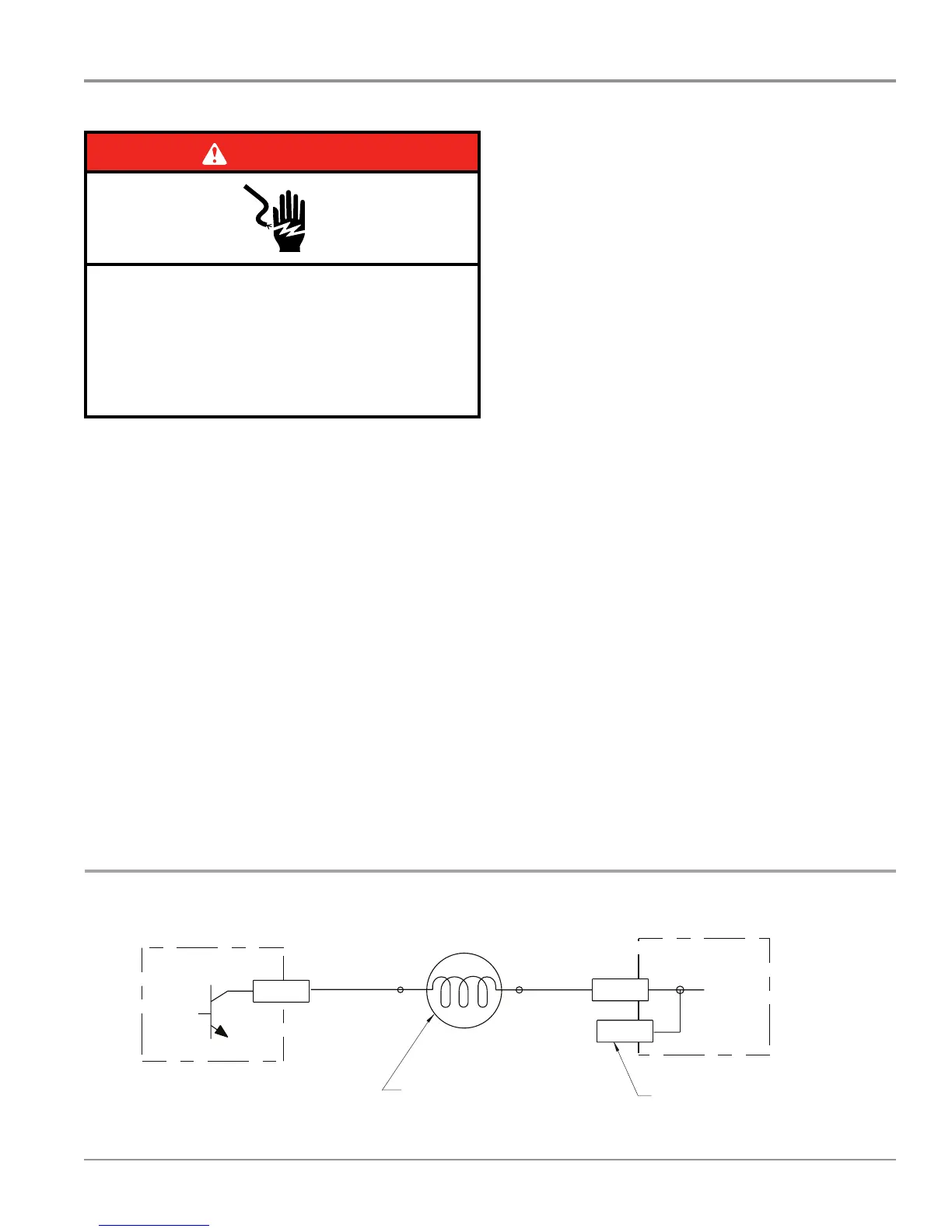

L1

BK BK

P4-2 P10-1

P10-3

P4-1

BR BR WH

N

N.O.

K2

Fuse

F9

Electronic Control

Electronic Control

Pin 5

Pin 1

Vent Wax Motor

600 Ω - 1,800 Ω

120V, 60 Hz, 6W

Electronic Control

Electronic Control

P10-5

P10-4

P11-5

DC Ref

BR

BR

Pin 1Pin 3

Fan Motor

31KΩ - 41K Ω

5 VDC, 1W

No test pad on P10-4.

Recommend using test pad on P11-5.

5V

_

+

-USTMEASURERESISTANCE

WITHCORRECTPOLARITYAND

DISCONNECTEDFROM

CONTROLS

Use top of hole of jumper

W2 as test point for F9.

Pilot L1 Relay

(Also see Door

Switch Circuit)

(Red stripe

on plug)

(Red stripe

on plug)

(Red stripe

on plug)

(Red stripe

on plug)

DC Fan (not on all models)

L1

BK

P4-2

P7-3

P10-1

P7-1

P4-1

N

WH

BUBU

K2

Fuse

F9

Pin 1

Pin 3

N.O.

Electronic Control

Electronic Control

Tr iac

No test pad on P7-3.Recommend

using test pad on P10-1

.

AC Fan (not on all models)

Use top of jumperW2

as test point for F9

.

AC Fan Motor

115V, 60Hz, 10.2W Ty pical

65Ω -75Ω

Pilot L1 Relay

(Also see Door

Switch Circuit)

DISPLAY TEST - ALL LEDs ON INTERVAL 24

ERROR 1 - MOST RECENT INTERVAL 23

7-SEG will display

FUNCTION code

(F#).

Pause

0.5 sec.

7-SEG will display

PROBLEM code (E#).

Pause

1 sec.

Repeat 3 times

unless

advanced by

Start/Resume

key.

If no error, 7-SEG

will display (F-).

If no error, 7-SEG will

display (E-).

ERROR 2INTERVAL 22

7-SEG will display

FUNCTION code

(F#).

Pause

0.5 sec.

7-SEG will display

PROBLEM code (E#).

Pause

1 sec.

Repeat 3 times

unless

advanced by

Start/Resume

key.

If no error, 7-SEG

will display (F-).

If no error, 7-SEG will

display (E-).

ERROR 3INTERVAL 21

7-SEG will display

FUNCTION code

(F#).

Pause

0.5 sec.

7-SEG will display

PROBLEM code (E#).

Pause

1 sec.

Repeat 3 times

unless

advanced by

Start/Resume

key.

If no error, 7-SEG

will display (F-).

If no error, 7-SEG will

display (E-).

ERROR 4 - OLDESTINTERVAL 20

7-SEG will display

FUNCTION code

(F#).

Pause

0.5 sec.

7-SEG will display

PROBLEM code (E#).

Pause

1 sec.

Repeat 3 times

unless

advanced by

Start/Resume

key.

If no error, 7-SEG

will display (F-).

If no error, 7-SEG will

display (E-).

10-second pause Hi Temp LED will be

on

INTERVAL 19

Press HI TEMP to clear errors.

Hi Temp LED will blink twice to indicate errors have

been cleared. If the Hi Temp key does not respond,

open and close the door to wake up the control

panel. Press HI TEMP to clear errors.

Service Diagnostics Cycle

Turns on loads and checks sensors.

INTERVALS 18-3

SERVICE CYCLE ERROR 1INTERVAL 2

7-SEG will display

FUNCTION code

(F#).

Pause

0.5 sec.

7-SEG will display

PROBLEM code (E#).

Pause

1 sec.

Repeat 3 times

unless

advanced by

Start/Resume

key.

If no error, 7-SEG

will display (F-).

If no error, 7-SEG will

display (E-).

SERVICE CYCLE ERROR 2INTERVAL 1

7-SEG will display

FUNCTION code

(F#).

Pause

0.5 sec.

7-SEG will display

PROBLEM code (E#).

Pause

1 sec.

RepeatTIMES

unless

advanced by

Start/Resume

key.

If no error, 7-SEG

will display (F-).

If no error, 7-SEG will

display (E-).

Loading...

Loading...