211

The integral calculation will be stopped when the deviation of the reference and feedback is greater than

the setting. This function is used for reducing overshoot and oscillation incurred by the integral action in

the dynamic process.

Output values used for limiting the integral adjustment:

When the PID output serves as the frequency reference, use the maximum output frequency as 100%.

When the PID output serves as the torque reference, use 300% rated torque as 100%.

0: Perform differential control for the deviation of reference value and feedback value

1: Perform differential control for feedback value, applicable to frequent and quick changes of the

reference value.

Output values used for limiting the differential adjustment.

When the PID output serves as the frequency reference, use the maximum output frequency as 100%.

When the PID output serves as the torque reference, use 300% rated torque as 100%.

This is not only the sampling cycle for the feedback, but also the control cycle for PID. The PID regulator

calculates once for each sampling cycle. The bigger the sampling cycle is, the slower the response

becomes.

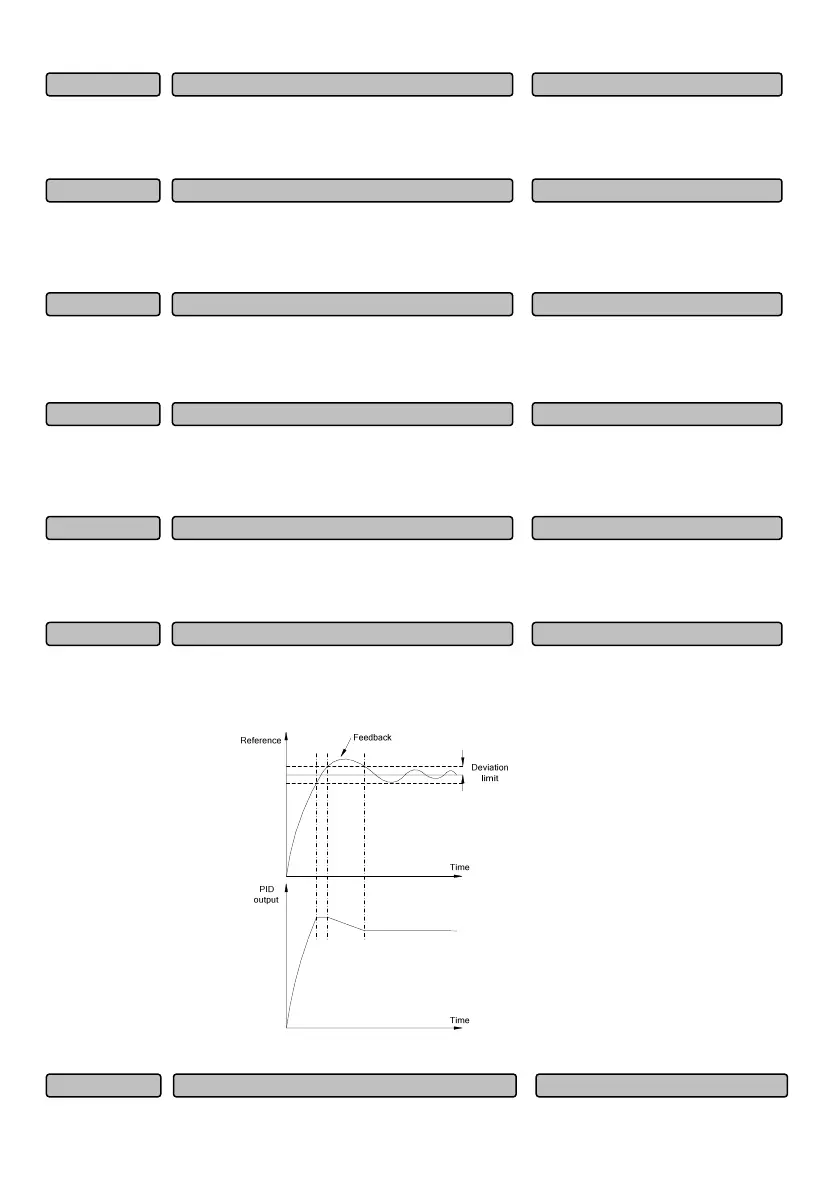

When the deviation of the reference value and feedback value relative to the percentage of reference

value is less than the deviation limit setting, the PID will stop adjusting and the output remains unchanged.

This function can avoid frequent actions of the PID control.

Fig. 6-73 Schematic diagram of deviation limit

PID u

er limit channel 0~3

0

P14.14

Deviation limit 0.0~20.0%

2.0%

P14.13

Sam

lin

c

cle 0.001~50.000s

0.010s

P14.12

Differential am

litude limit 0.0~100.0%

10.0%

P14.11

Differential control selection 0~1

0

P14.10

Inte

ral am

litude limit 0.0~100.0%

100.0%

P14.09

Inte

ral se

aration threshol

0.0~100.0%

30.0%

P14.08

Loading...

Loading...