Section 5 - Maintenance

Page 110 90-879172181 eng FEBRUARY 2011

Tube Ref No. Description Where Used Part No.

94

Anti-Corrosion Grease Propeller shafts 92-802867Q 1

34

Special Lubricant 101 Propeller shaft 92-802865Q02

95

2-4-C Marine Lubricant

with Teflon

Propeller shaft 92-802859A 1

3. Install the propellers. Refer to Propellers.

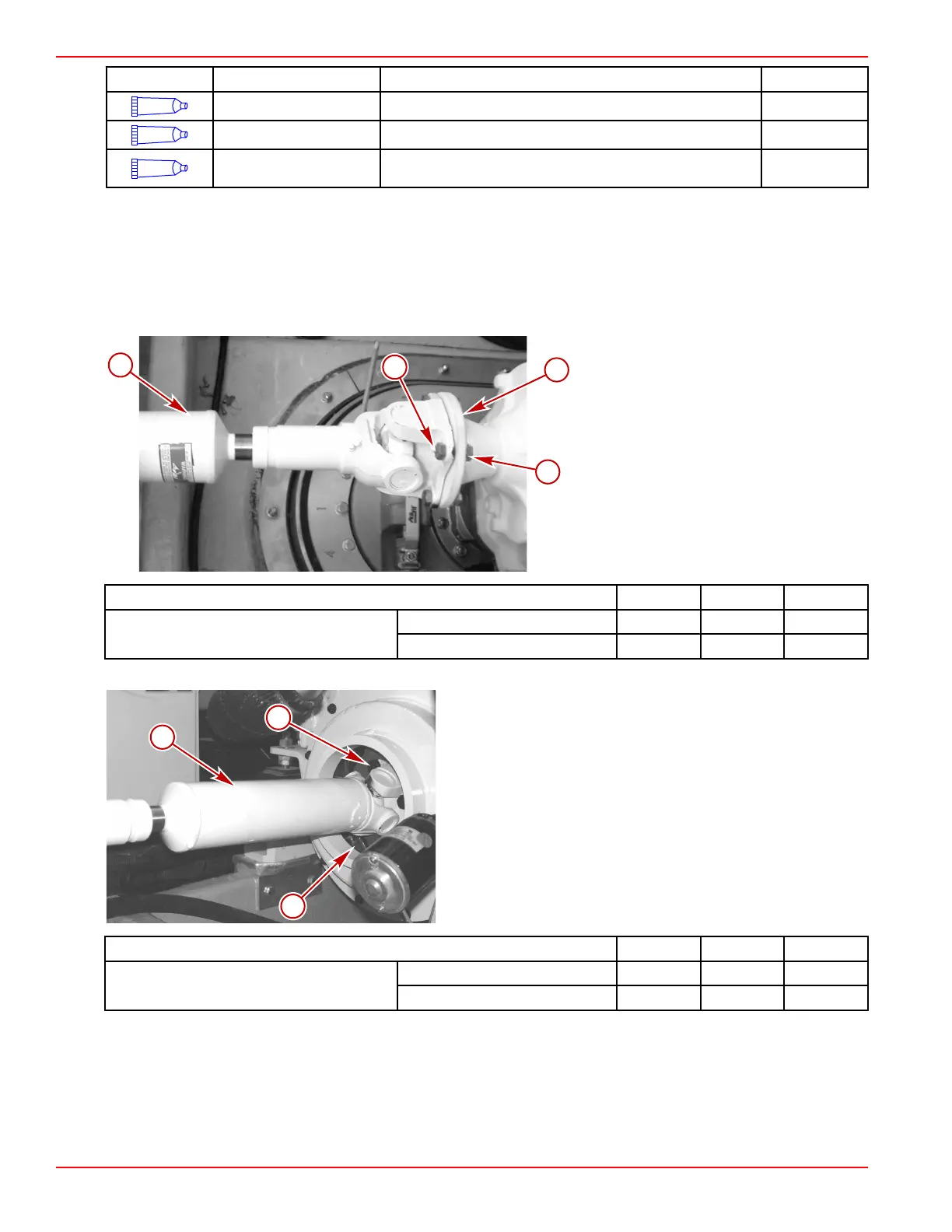

Driveshaft Connection Torque

1. Remove the engine and transmission end driveshaft shields, if not already. Refer to Driveshaft U-Joints.

2. Tighten the driveshaft flange to the transmission input flange bolts and nuts as specified.

NOTE: Some models have larger diameter transmission input and driveshaft flanges (175 mm [6.88 in.]) and use eight bolts

and nuts. Ensure the bolts and nuts are at least Grade 8 fasteners before tightening.

Typical four-bolt flange shown, eight-bolt

similar

a - Locknut

b - Transmission input shaft flange

c - Bolt, four total (QSB, QSC), eight total

(QSM), per flange

d - Driveshaft

Description Nm lb. in. lb. ft.

Transmission input shaft flange locknut

Four‑bolt flange 149 – 110

Eight‑bolt flange 61 – 45

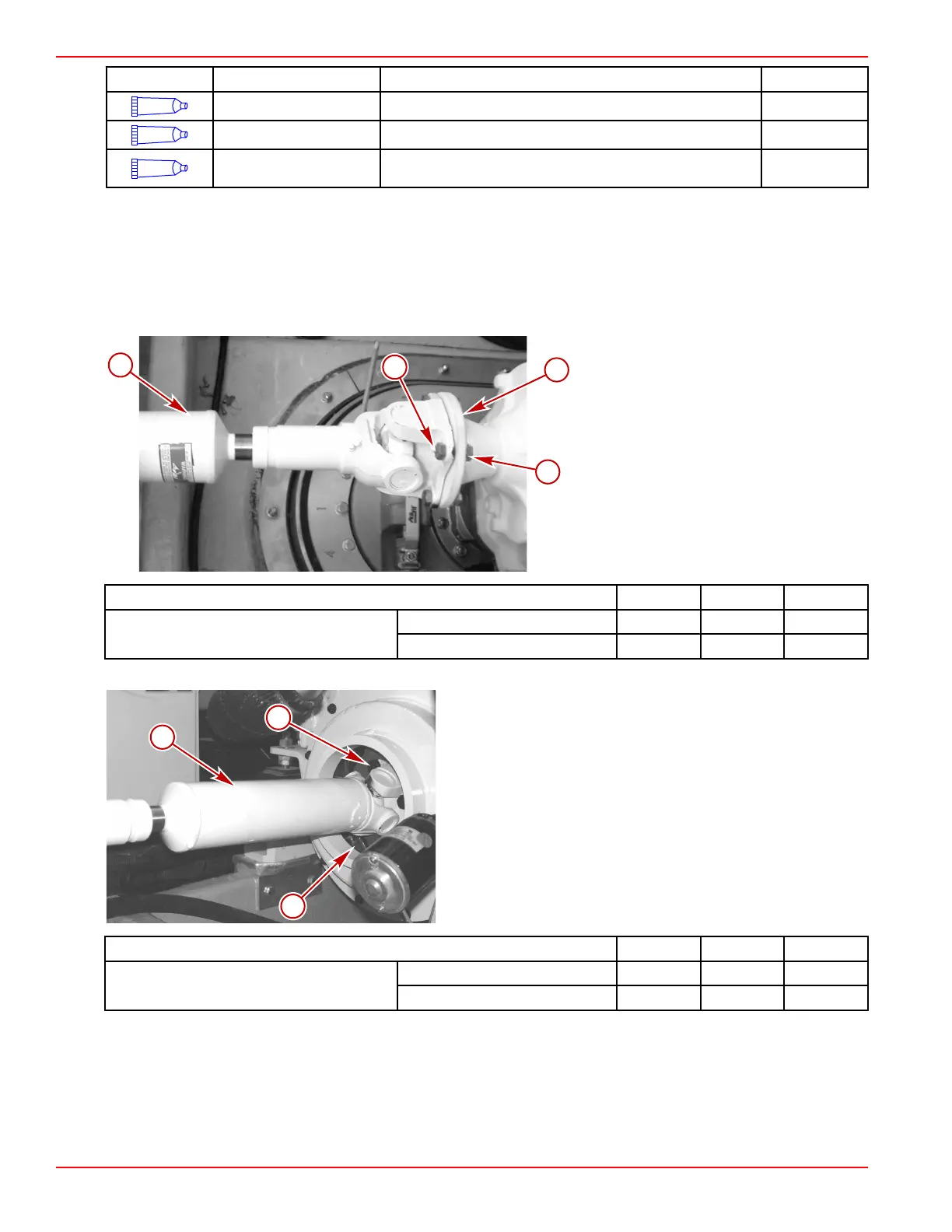

3. Tighten the driveshaft input flange screws to the engine coupler as specified.

Typical four-screw flange shown, eight-screw similar

a - Screw, four total (QSB, QSC), eight total (QSM), per

flange

b - Engine coupler flange

c - Driveshaft

Description Nm lb. in. lb. ft.

Engine coupler‑to‑drive shaft flange screw

Four‑screw flange 149 – 110

Eight‑screw flange 61 – 45

Loading...

Loading...