3 Removal and Disassembly

8

Meritor Maintenance Manual MM-15103 (Issued 07-17)

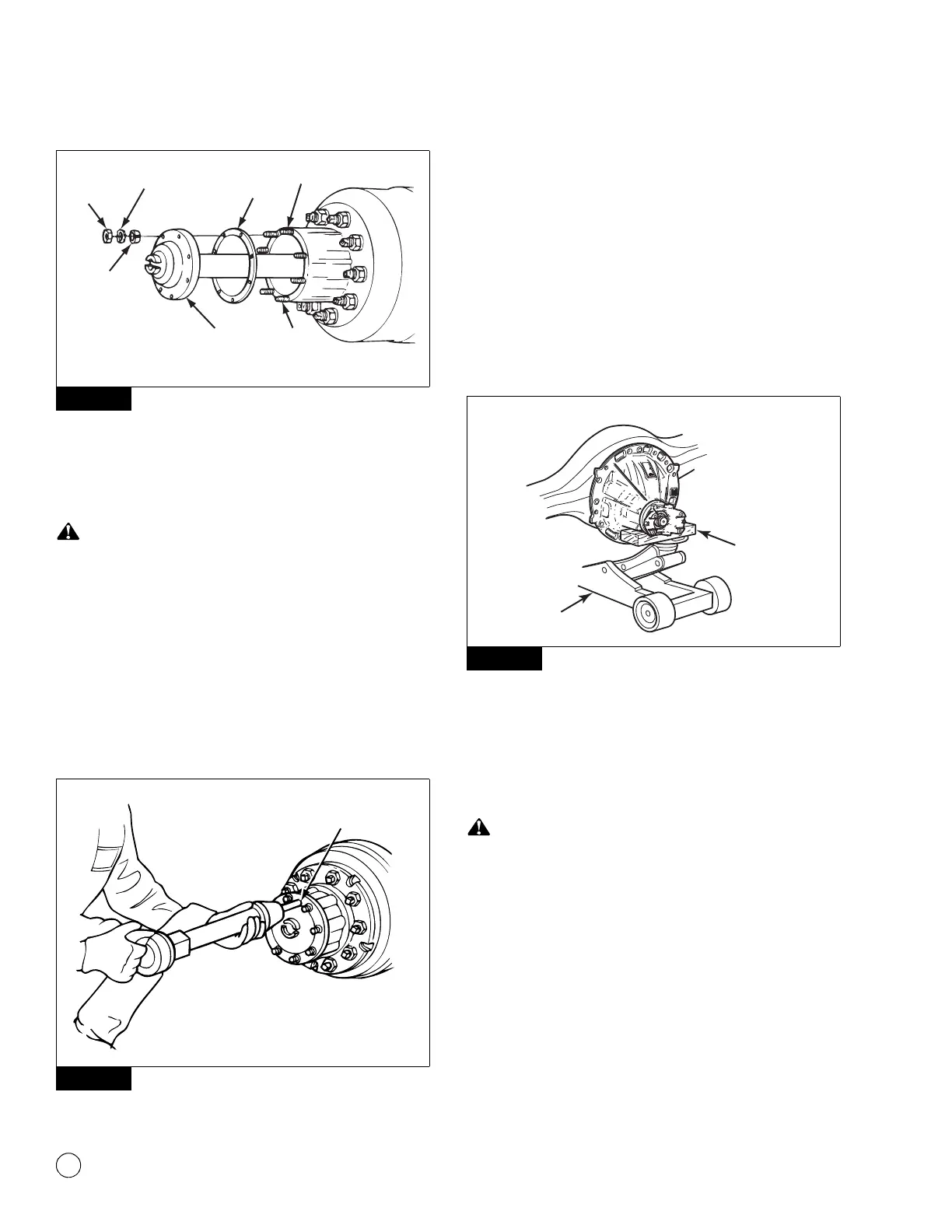

Figure 3.4

5. Install a cover over the open end of each axle assembly hub

where an axle shaft was removed.

Air Hammer Vibration Method

Do not use a chisel or wedge to loosen the axle shaft and

tapered dowels, which can damage the axle shaft, gasket and

seal, and axle hub.

1. Use a round hammer bit and an air hammer to loosen the

tapered dowels and axle shaft.

2. Place the round hammer bit against the axle shaft between the

hub studs. Operate the air hammer at alternate locations

between the studs to loosen the tapered dowels and axle shaft

from the hub. Figure 3.5.

Figure 3.5

3. Mark each axle shaft to identify it before you remove it from the

axle assembly.

4. Remove the tapered dowels. Separate the axle shaft from the

main axle hub assembly. Figure 3.4.

5. Install a cover over the open end of each axle assembly hub

where an axle shaft was removed.

Differential Carrier from the Axle Housing

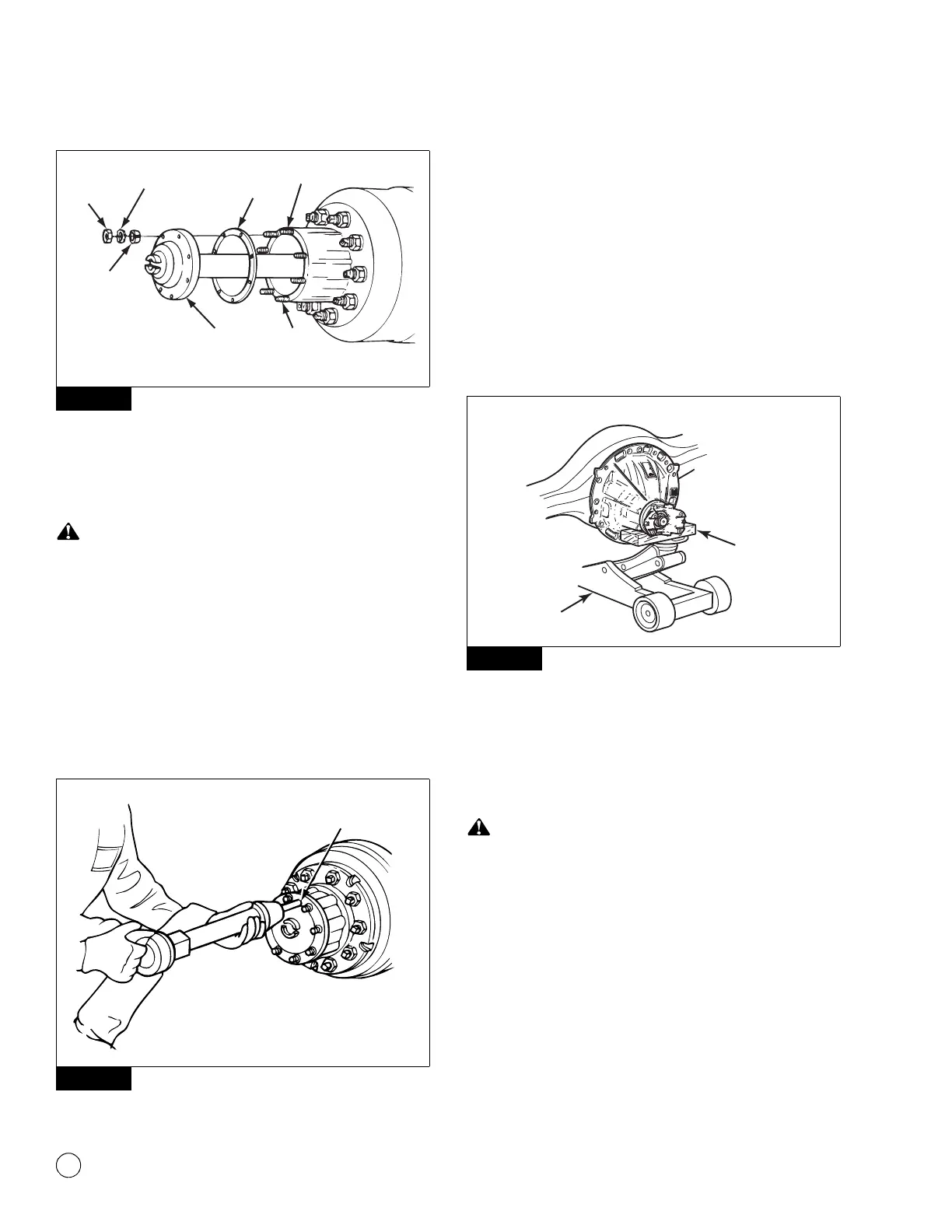

1. Place a hydraulic roller jack under the differential carrier to

support the assembly. Figure 3.6.

Figure 3.6

2. Remove all but the top two carrier-to-housing capscrews or

stud nuts and washers.

3. Loosen the top two carrier-to-housing fasteners, but leave

them attached to the assembly. The fasteners will hold the

carrier in the housing.

Use a brass or synthetic mallet for assembly and disassembly

procedures. Do not hit steel parts with a steel hammer. Pieces

of a part can break off. Serious personal injury and damage to

components can result.

4. Loosen the differential carrier in the axle housing. Use a leather

mallet to hit the mounting flange of the carrier at several

points.

5. After the carrier is loosened, remove the top two fasteners.

Figure 3.4

Figure 3.5

1002581d

TAPERED

DOWEL,

IF EQUIPPED

GASKET

STUD

HUBAXLE

SHAFT OR

FLANGE

STUD

NUT

WASHER

ROUND HAMMER BIT

BETWEEN HUB STUDS

1002987a

Figure 3.6

WOOD

BLOCK

ROLLER

JACK

4011956a

Loading...

Loading...