5 Assembly and Installation

43

Meritor Maintenance Manual MM-15103 (Issued 07-17)

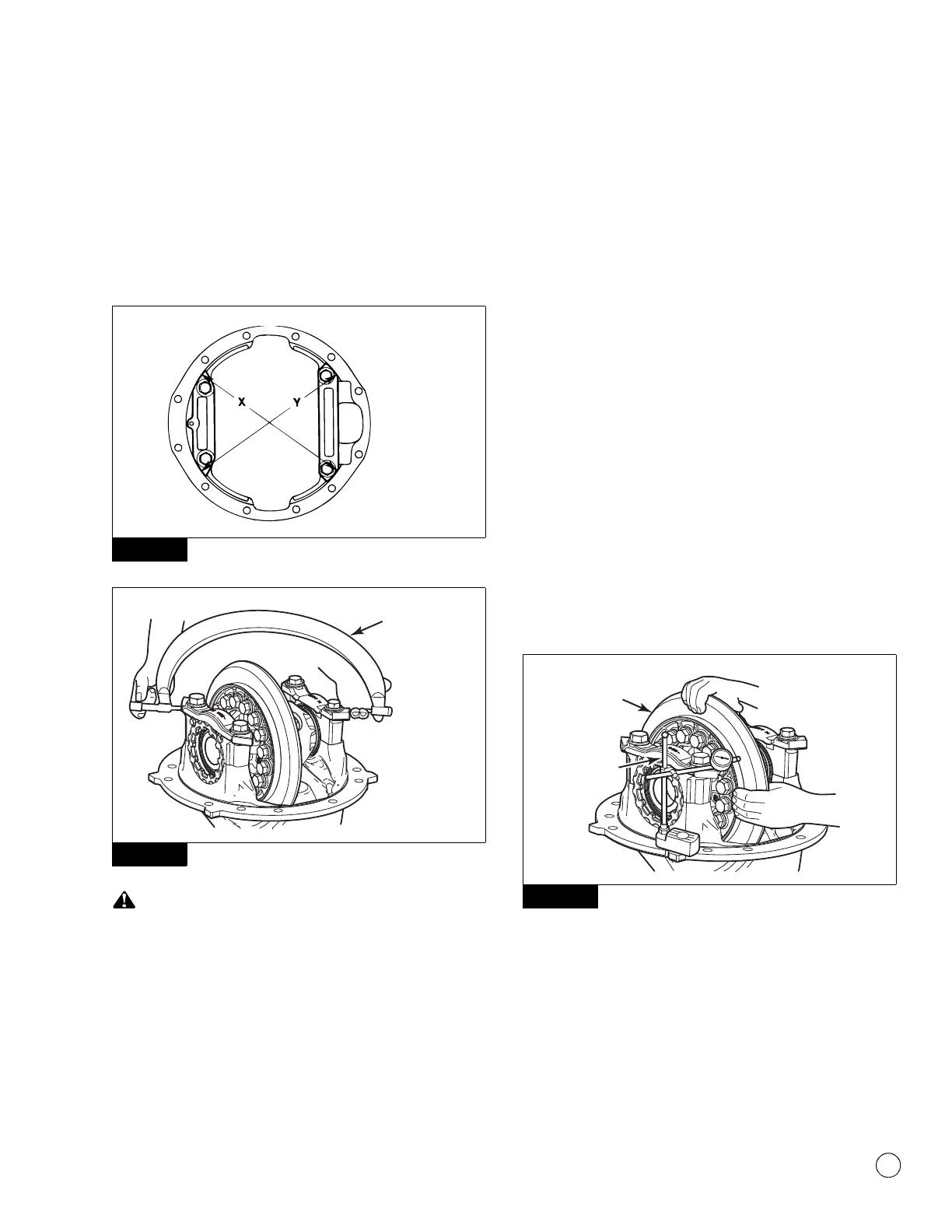

Large Micrometer Method

1. Hand-tighten the adjusting rings against the differential

bearings.

2. Use a large 13-14-inch micrometer to measure distance X and

Y between the opposite surfaces of the bearing caps. Record

the measurement. Figure 5.63 and Figure 5.64.

Figure 5.63

Figure 5.64

When turning the adjusting rings, always use a tool that

engages two or more opposite notches in the ring. An

adjusting ring tool can be used for this purpose. If the tool does

not correctly fit into the notches, damage to the lugs will occur.

3. Use an adjusting ring tool to tighten each bearing adjusting ring

one notch. Figure 5.59.

4. Measure distance X and Y again. Compare the measurements

with the distances X and Y measured in Step 2. The difference

between the two distances is the amount the bearing caps

have expanded. Refer to Table D.

Table D: Example

5. If the difference is at or between 0.002-0.009-inch

(0.05-0.23 mm): Continue by checking the runout.

If the difference is not within 0.002-0.009-inch

(0.05-0.23 mm): Repeat as needed.

Ring Gear Runout

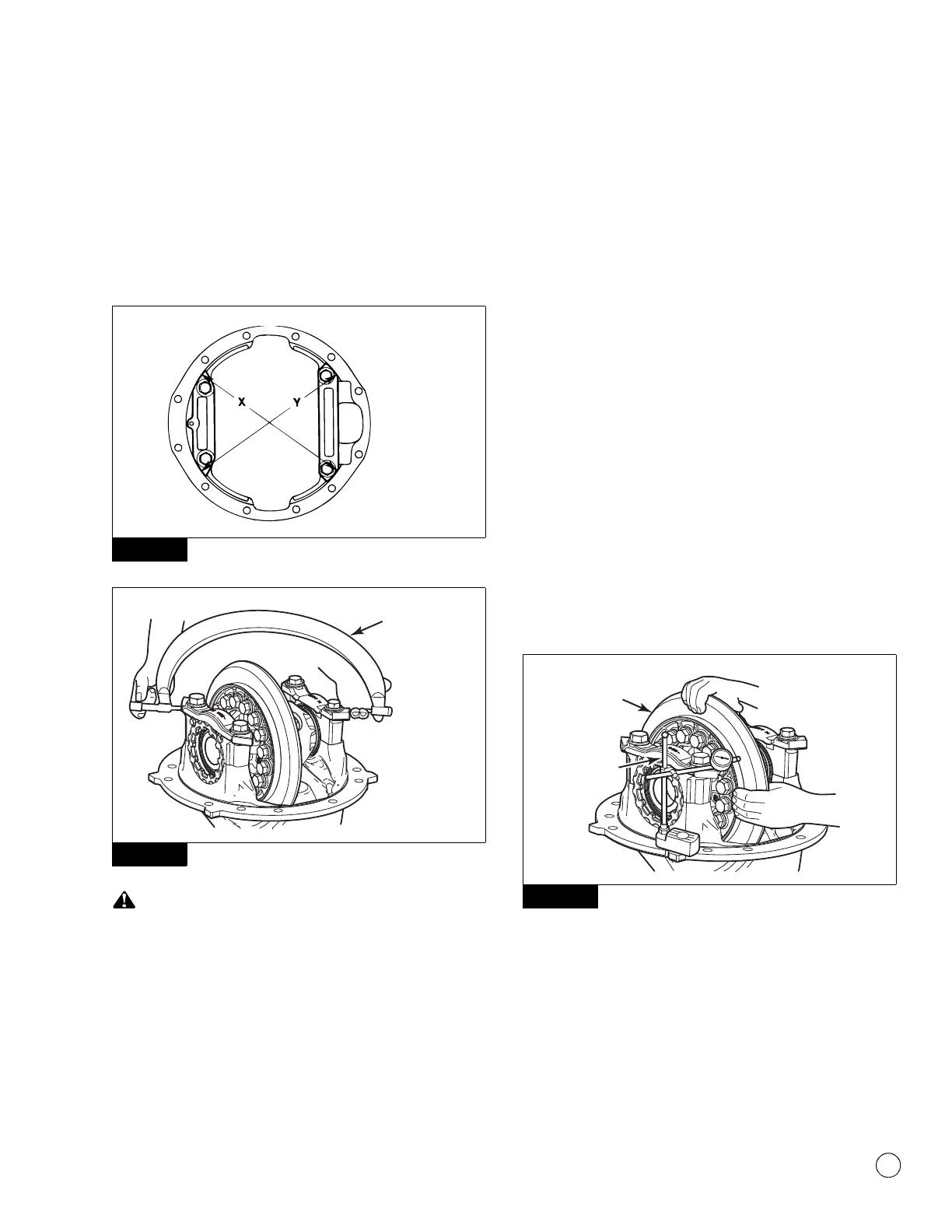

1. Attach a dial indicator onto the carrier mounting flange.

Figure 5.65.

Figure 5.65

2. Adjust the dial indicator so that the plunger or pointer is against

the back surface of the ring gear. Figure 5.65. Set the dial

indicator to ZERO.

3. Rotate the differential and ring gear. Read the dial indicator.

The ring gear runout must not exceed 0.008-inch (0.200 mm).

Figure 5.63

Figure 5.64

Distances X and Y BEFORE

tightening the adjusting rings

= 13.927-inches (353.75 mm)

Distances X and Y AFTER

tightening the adjusting rings

= 13.932-inches (353.87 mm)

13.932-inches –

13.927-inches

= 0.005-inch difference

353.87 mm – 353.75 mm = 0.12 mm difference

Figure 5.65

4012314a

DIAL

INDICATOR

Rotate ring

gear.

Loading...

Loading...