4 Prepare Parts for Assembly

21

Meritor Maintenance Manual MM-15103 (Issued 07-17)

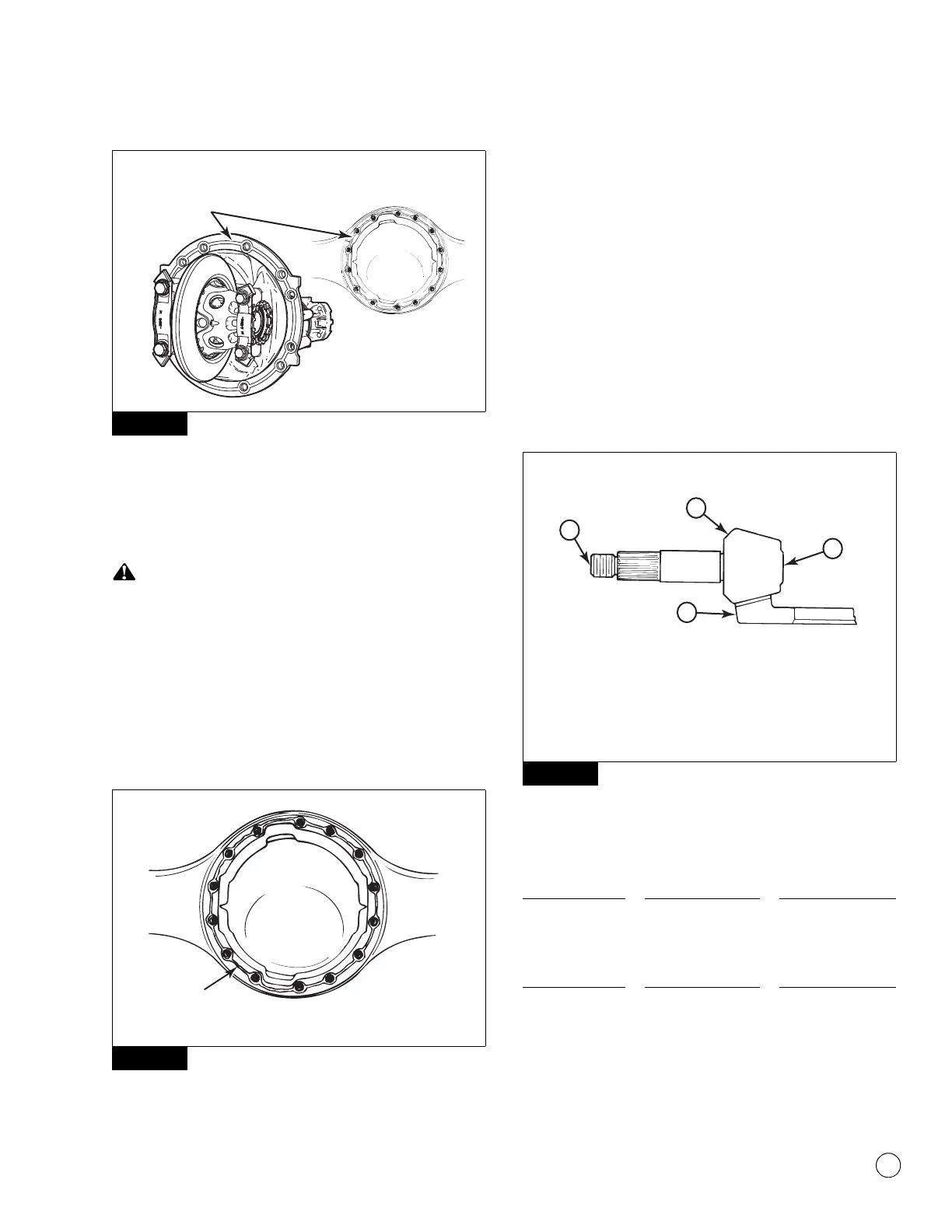

Figure 4.11

2. Use a cleaning solvent to clean the surfaces where you will

apply silicone gasket material. Remove all oil, grease, dirt and

moisture without damaging the mating surfaces. Figure 4.11.

3. Dry all surfaces.

Apply silicone gasket material in a continuous 0.25-inch

(6 mm) bead. If you use more than this amount, the gasket

material can break off and plug lubrication passages. Damage

to components can result.

4. Apply a 0.25-inch (6 mm) diameter continuous bead of the

silicone gasket material around one surface. Also apply the

gasket material around the edge of all fastener holes on that

surface. Figure 4.12.

Figure 4.12

5. Assemble the components immediately to permit the silicone

gasket material to compress evenly between the parts. Tighten

fasteners to the required torque value for that size fastener.

Refer to Table H in Section 7.

6. Wait 20 minutes before filling the assembly with the correct

lubricant. Refer to Section 4.

Identification

Gear Sets

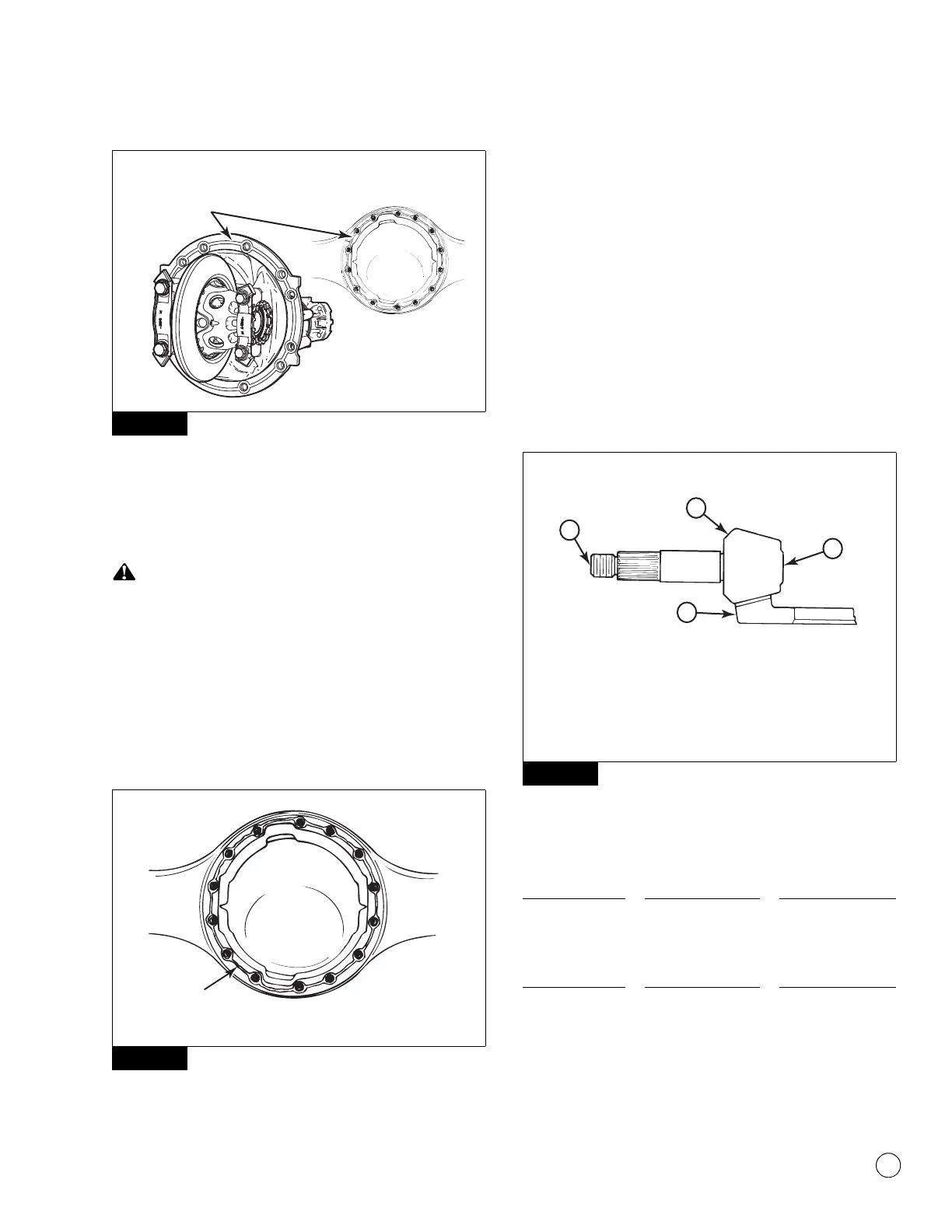

Refer to the following examples for information on identifying gear

sets with matched parts. Always check the match numbers to verify

that the gear set you will install has matched parts. Figure 4.13.

Figure 4.13

Examples

Gear Set

Figure 4.11

Figure 4.12

4012514a

Remove old

sealant

material.

HOUSING AND CARRIER SHOWN

0.25" (6 MM)

DIAMETER SILICONE

GASKET BEAD

1003028f

Figure 4.13

1 PART NUMBER, TOOTH COMBINATION NUMBER, GEAR SET MATCH

NUMBER, PINION CONE VARIATION NUMBER

2 PART NUMBER, TOOTH COMBINATION NUMBER

3 GEAR SET MATCH NUMBER, PINION CONE VARIATION NUMBER

4 PART NUMBER, TOOTH COMBINATION NUMBER, GEAR SET MATCH

NUMBER

Part Number Location

Conventional

ring gear

XXXXX, XXXXXK2,

XXXXXK3,

XXXXXK4,

XXXXXK5

On the outer

diameter

Conventional

drive pinion

XXXXX, XXXXXK2,

XXXXXK3,

XXXXXK4,

XXXXXK5

At the end at

threads

1003031d

ALTERNATE LOCATIONS

2

1

4

3

Loading...

Loading...