5 Assembly and Installation

41

Meritor Maintenance Manual MM-15103 (Issued 07-17)

Correctly install the bearing caps into their original locations

on the carrier. Do not force the bearing caps into position,

which can damage the carrier. If the bearing caps are not

installed correctly, the bores and threads in the cap will not

match the carrier. Damage to the adjusting rings by

cross-threading can result.

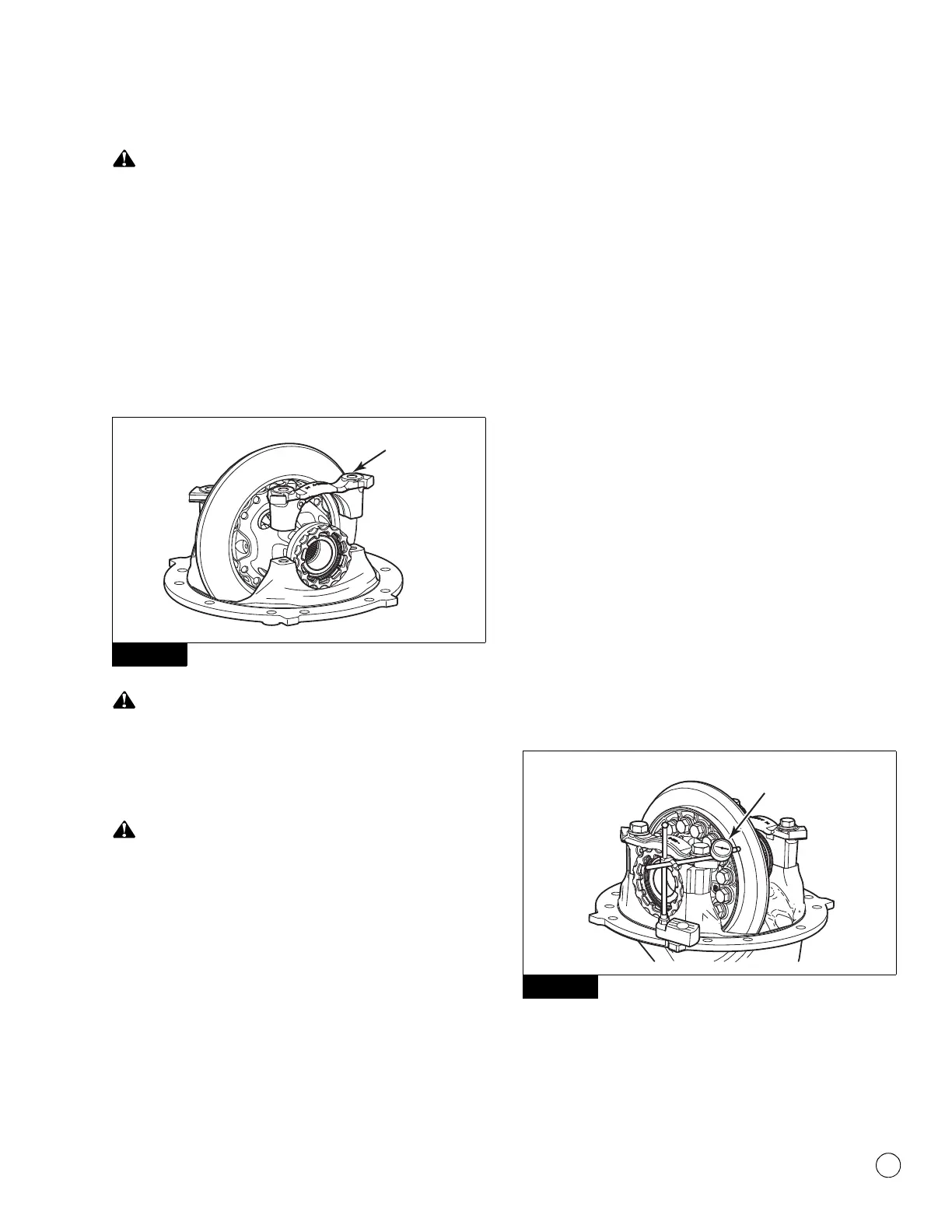

8. Install the bearing caps over the bearings and adjusting rings in

the correct location. Check the shape of the mounting face on

the carrier legs to ensure the bearing caps are installed in the

correct position. Figure 5.57.

Figure 5.57

Use a brass or synthetic mallet for assembly and disassembly

procedures. Do not hit steel parts with a steel hammer. Pieces

of a part can break off. Serious personal injury and damage to

components can result.

Correctly install the bearing caps into their original locations

on the carrier. Do not force the bearing caps into position,

which can damage the carrier. If the bearing caps are not

installed correctly, the bores and threads in the cap will not

match the carrier. Damage to the adjusting rings by

cross-threading can result.

9. Use a light leather, plastic or rubber mallet to seat each bearing

cap. The caps must fit easily against the bearings, adjusting

rings and carrier. Do not force the bearing caps into position.

앫 If the bearing caps do not correctly fit into position:

Check that the bearing caps are installed in the correct

position. Remove the caps and reinstall them.

10. Hand-tighten the adjusting rings against the bearing cups to

position the ring gear to the pinion with 0.012-inch (0.3 mm)

backlash.

11. Install the capscrews and washers that secure the bearing

caps to the carrier. Tighten the capscrews to 25 lb-ft (34 N폷m).

This is an initial tightening torque and will be increased later in

the procedure.

@

Do not install the capscrews and washers that secure the

bearing adjusting rings in position. After the ring gear is

installed, you must adjust the backlash of the ring gear, inspect

the tooth contact patterns, then adjust the preload of the

differential bearings before the capscrews and washers are

installed.

Adjustment

Differential Bearings Preload

Use either the dial indicator or the large micrometer method to

inspect and adjust the main differential side bearings preload.

NOTE: The capscrews and washers for the adjusting rings are

installed after the tooth contact pattern is rechecked.

Dial Indicator Method

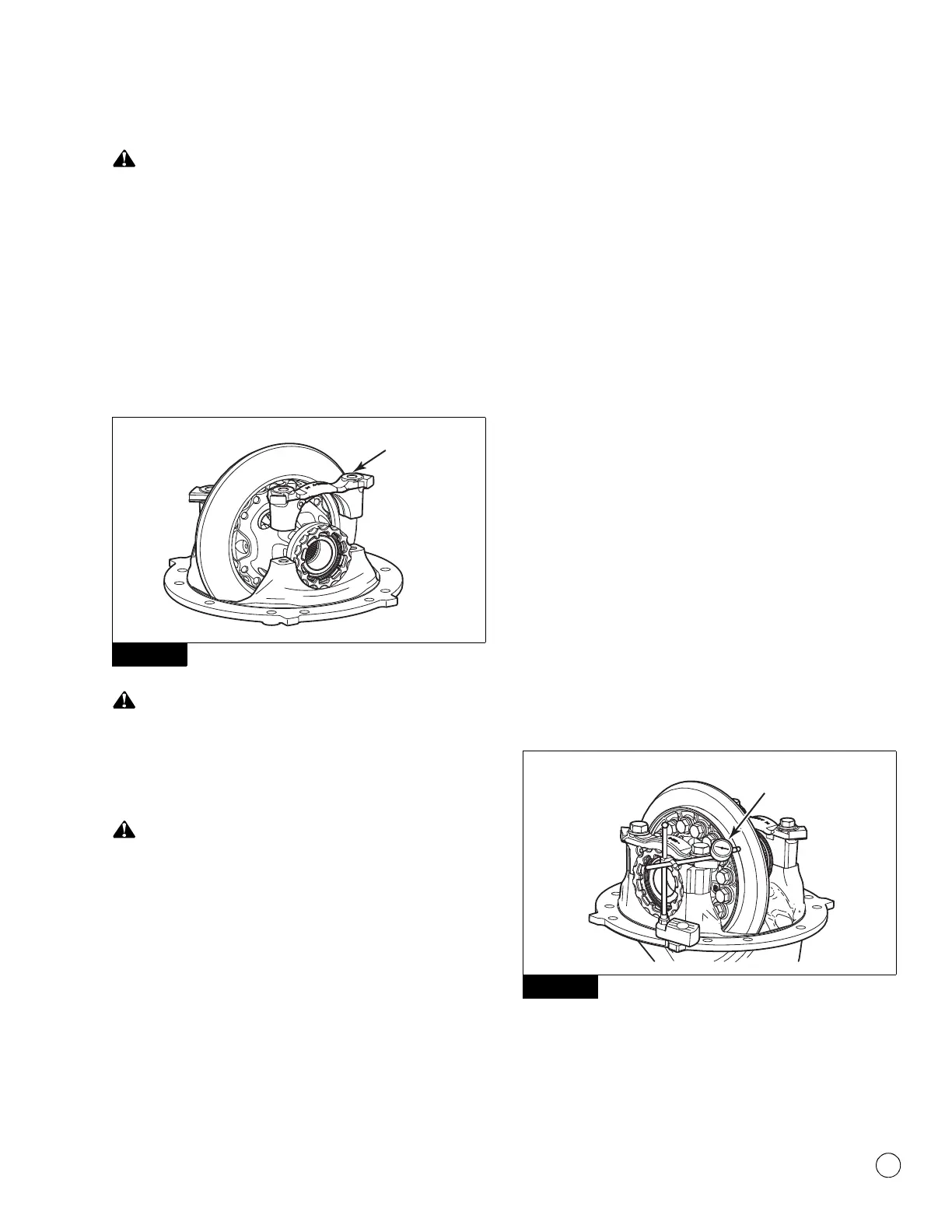

1. Attach a dial indicator onto the carrier mounting flange so that

the plunger or the pointer is against the back surface of the

ring gear. Figure 5.58.

Figure 5.58

Figure 5.57

Figure 5.58

4011994a

DIAL

INDICATOR

Loading...

Loading...