5 Assembly and Installation

40

Meritor Maintenance Manual MM-15103 (Issued 07-17)

앫 To increase preload: Install a thinner bearing variable

spacer.

앫 To decrease preload: Install a thicker bearing variable

spacer.

8. Once the desired preload is obtained, remove the used yoke.

Install the seal and the service yoke. Refer to the procedures in

this section.

Replace the Variable Spacer to Adjust Pinion

Bearing Preload

NOTE: Do not grind spacers by hand. The surfaces must be parallel

within 0.0001-inch (0.0020 mm). You must use the correct

spacers.

If you must adjust preload, use the following procedure to replace

the variable spacer with one of a different thickness.

1. Install a yoke or flange bar to prevent the drive pinion assembly

from rotating. Remove the nut and the washer from the shaft of

the drive pinion.

2. Press the drive pinion out of the bearing cone. Remove the

outer bearing cone from the differential carrier.

3. Reinstall the drive pinion assembly using the correct size

variable spacer.

4. Recheck the drive pinion bearing preload using the procedure

in this section.

“Final” Installation of the Main Differential

Case and Ring Gear Assembly Into the

Carrier

1. Rotate the carrier in the repair stand until the back surface of

the ring gear is toward the TOP.

2. Clean and dry the bearing cups and bores of the carrier legs

and bearing caps.

3. Apply axle lubricant to the bearing cones and inside surface of

the bearing cups.

NOTE: Meritor specification 2297-P-3994 adhesive will dry in

approximately two hours. You must complete the procedure within

two hours from the time you apply the adhesive. If two hours have

passed since application, clean the adhesive from the parts and

apply new adhesive.

4. Apply Meritor specification 2297-P-3994, Loctite

680

adhesive or equivalent 360 degrees around the outside

diameter of the bearing cups. The adhesive must not contact

the adjusting ring threads. Refer to Section 4.

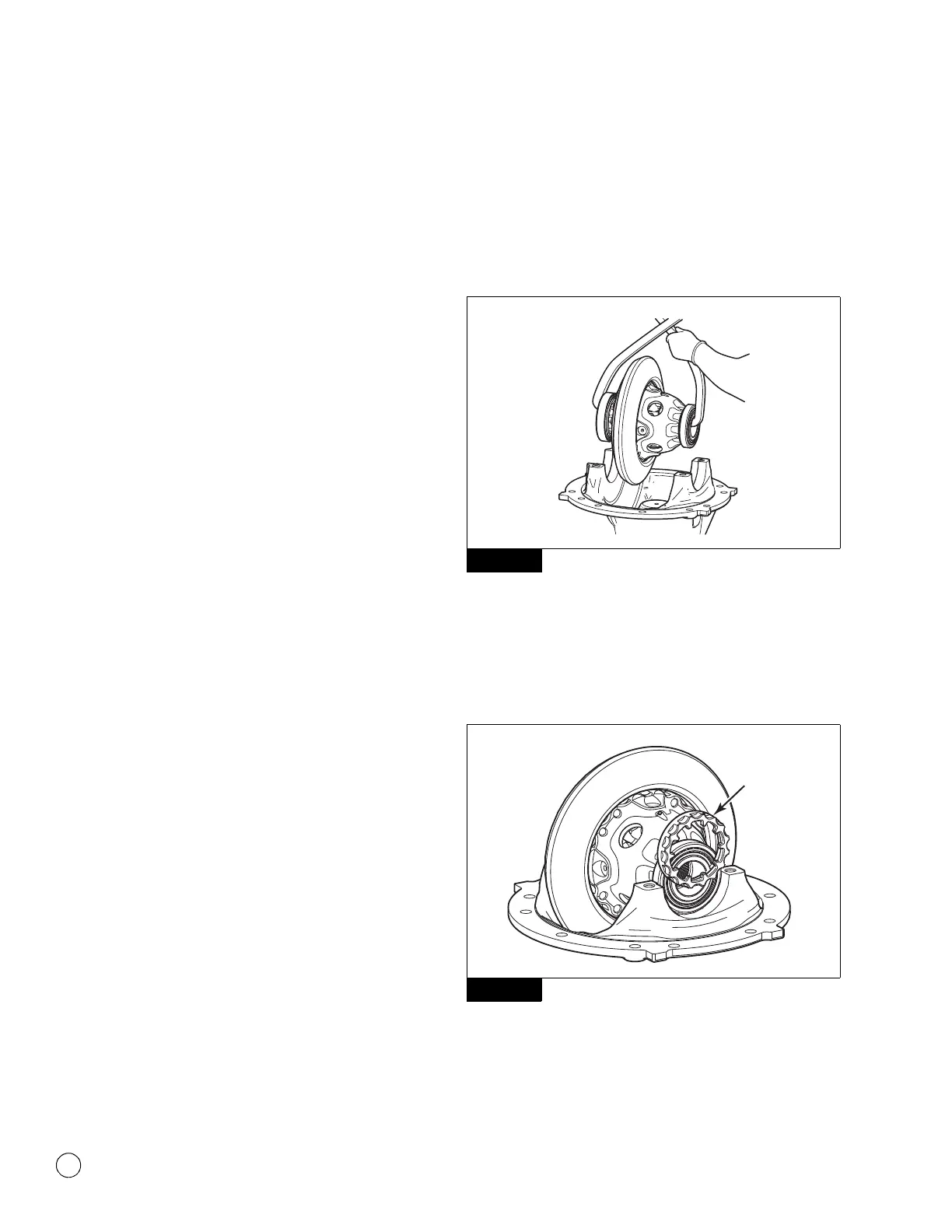

5. Install the bearing cups over the bearing cones in the case

halves. Figure 5.55.

Figure 5.55

6. Safely lift the differential and ring gear assembly and install it

into the carrier. The bearing cups must be flat against the

bores between the carrier legs. Figure 5.55.

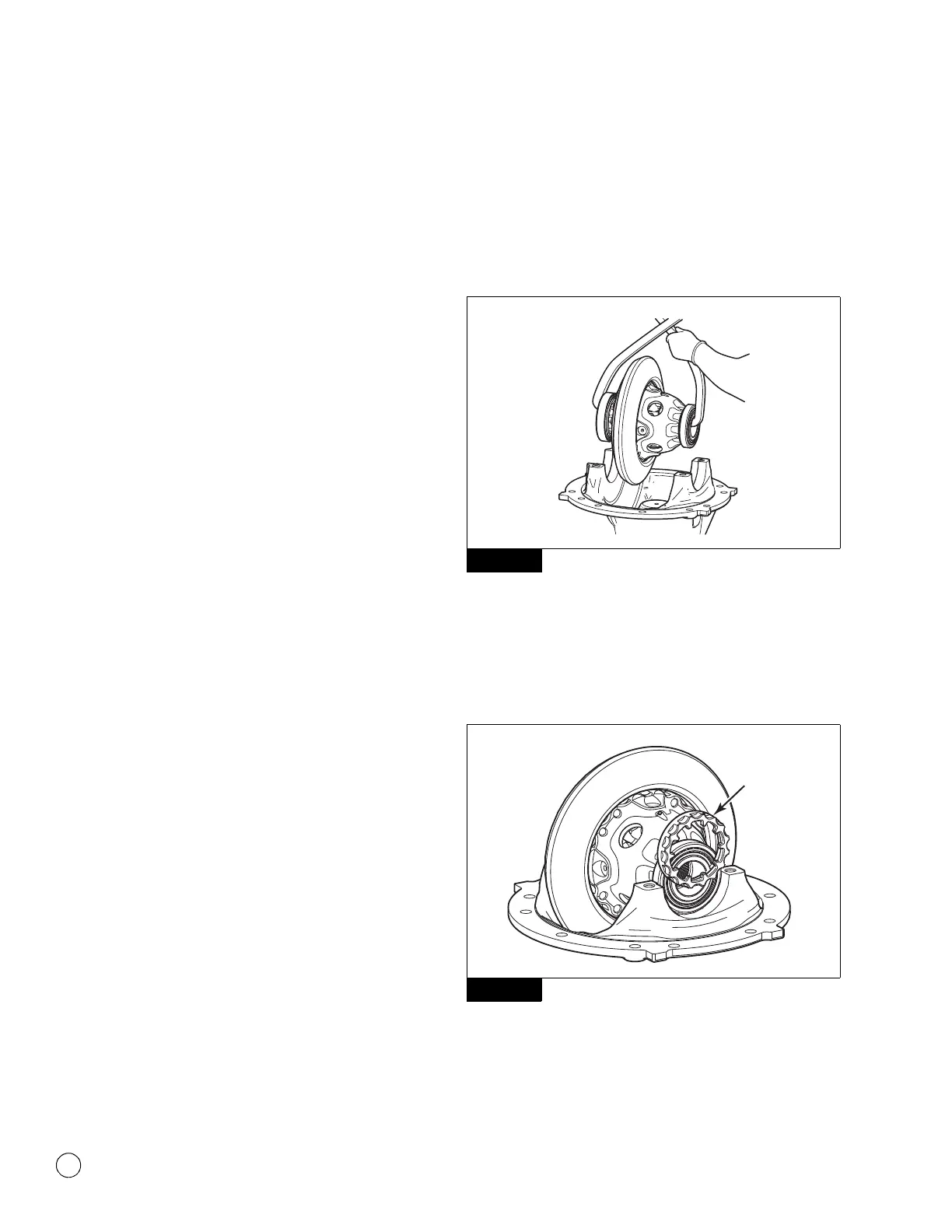

7. Install the bearing adjusting rings between the carrier legs.

Figure 5.56.

Figure 5.56

Figure 5.55

Figure 5.56

4011964a

4012324a

ADJUSTING

RING

Loading...

Loading...