4 Prepare Parts for Assembly

23

Meritor Maintenance Manual MM-15103 (Issued 07-17)

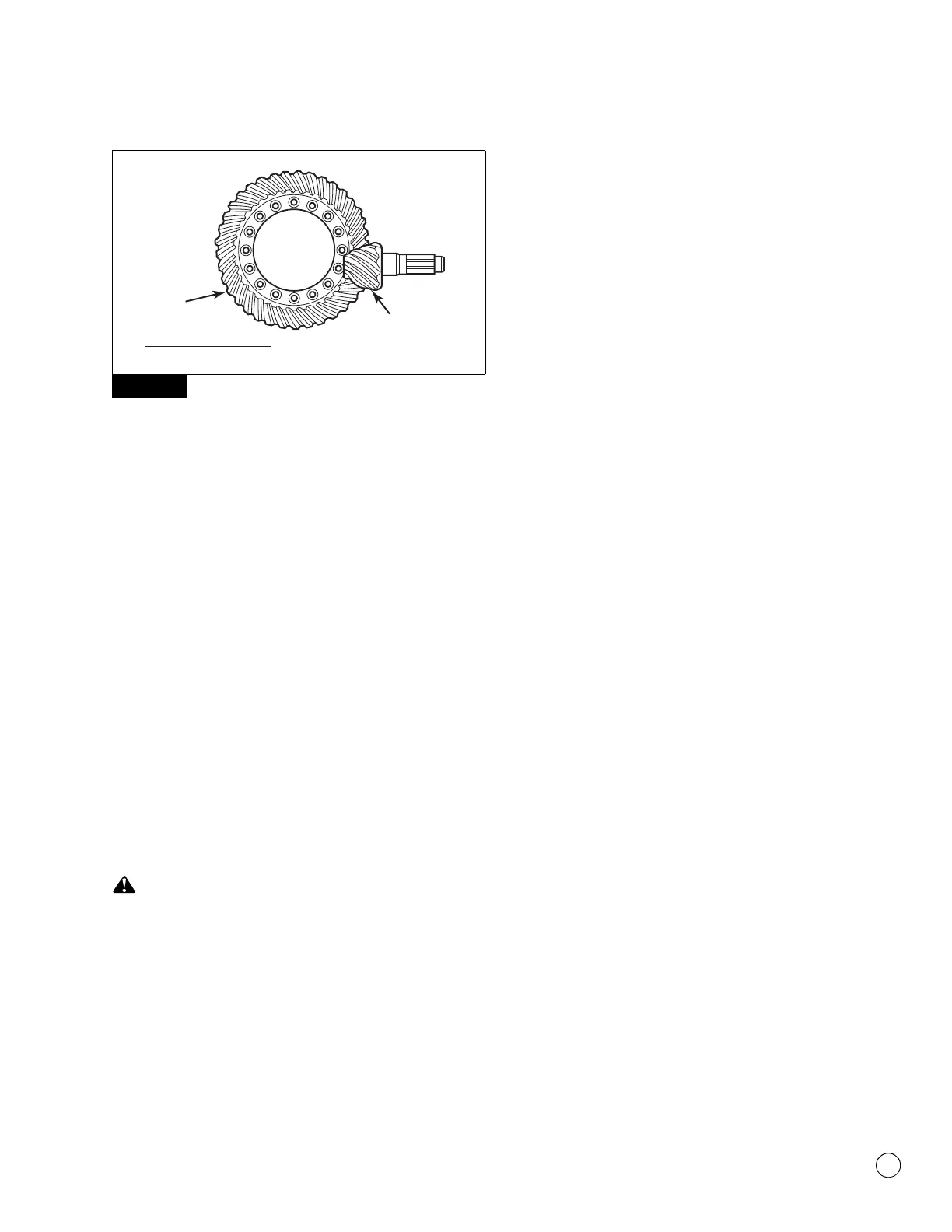

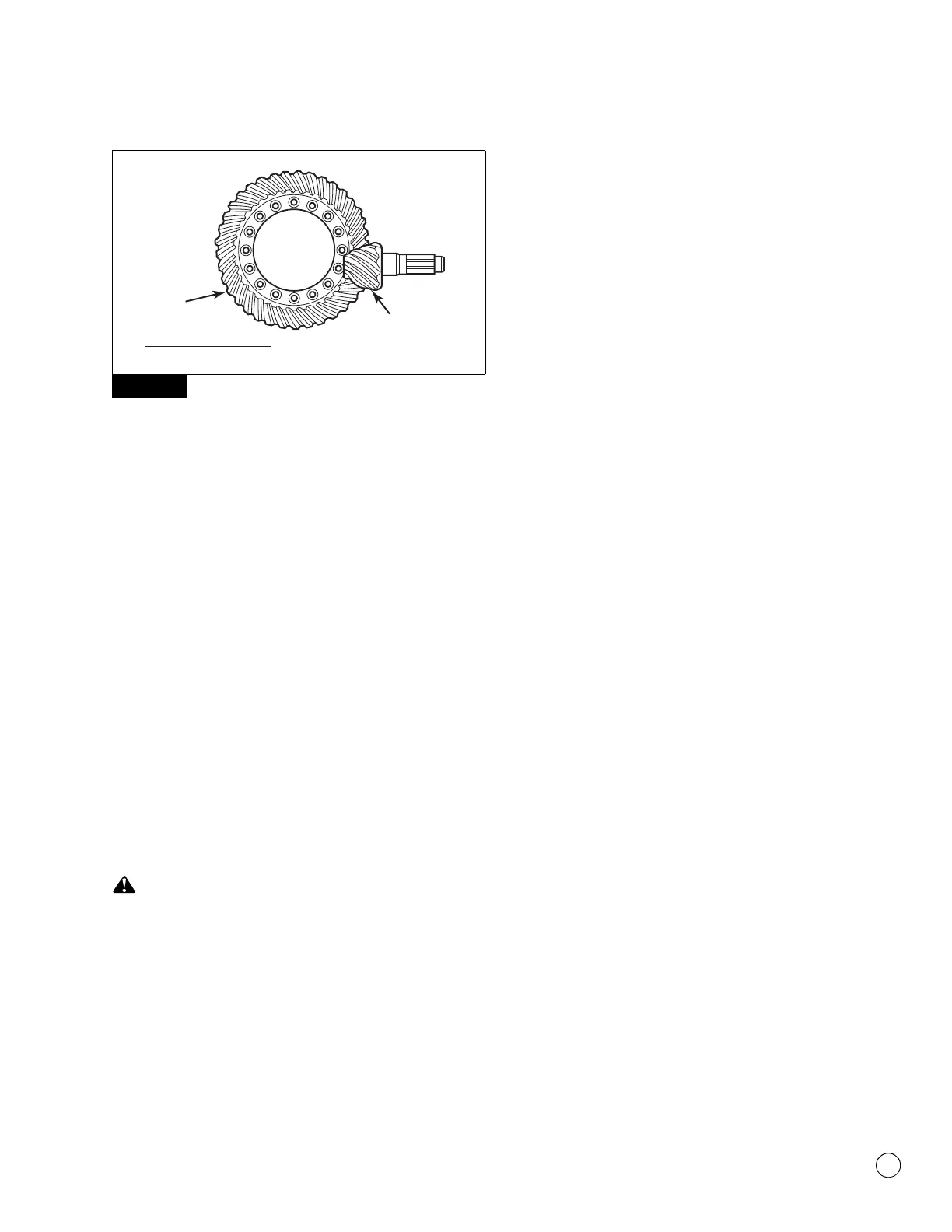

Figure 4.15

2. Count the number of pinion gear teeth. Figure 4.15.

3. Divide the number of ring gear teeth by the number of pinion

gear teeth to determine the actual gear set ratio for each axle.

Figure 4.15.

4. Calculate the percentage difference between the gear set

ratios. All ratios must match within one percent.

앫 If the actual gear set ratios are not within one percent

of each other: Refer to the vehicle manufacturer for further

information.

Inspection

Yoke

All current Meritor axles feature helical splines at the yoke interface.

This feature provides a tight fit between the yoke and input shaft,

output shaft and pinion shaft. For the axle to operate correctly, the

input shaft, output shaft and pinion shaft must fit tightly to the

corresponding yoke.

Check for Yoke Wear

Park the vehicle on a level surface. Block the wheels to

prevent the vehicle from moving. Support the vehicle with

safety stands. Do not work under a vehicle supported only by

jacks. Jacks can slip and fall over. Serious personal injury and

damage to components can result.

1. Park the vehicle on a level surface. Block the wheels to prevent

the vehicle from moving.

2. Use a jack to raise the vehicle so that the wheels to be serviced

are off the ground. Support the vehicle with safety stands.

3. Remove the driveline.

4. Remove the pinion shaft nut.

5. Attempt to remove the yoke by hand.

앫 If you can remove the yoke by hand: The yoke is worn.

Replace the yoke.

6. Use a correct yoke puller tool to remove the yoke.

Check for a Tight-Fit Condition

NOTE: You can check for a tight-fit condition when you install any

serviceable yoke.

1. Attempt to install the yoke by hand.

앫 If the yoke bottoms out against the adjacent bearing:

Replace the yoke.

2. Use a correct yoke installation tool to install the yoke.

3. As you install the yoke, you should detect resistance between

the yoke and shaft.

앫 If you do not detect resistance between the yoke and

shaft: Replace the yoke.

4. Install and tighten the pinion shaft nut to the correct torque.

Refer to Section 7.

5. Install the driveline.

6. Remove the safety stands.

7. Lower the vehicle.

Figure 4.15

4012516a

RING GEAR TEETH

PINION GEAR TEETH

=

ACTUAL

GEAR SET RATIO

PINION

GEAR TEETH

RING

GEAR

TEETH

Loading...

Loading...