5 Assembly and Installation

44

Meritor Maintenance Manual MM-15103 (Issued 07-17)

앫 If the ring gear runout is within the specification: Set

the backlash and contact patterns to the settings

determined in the “Check Gear Set Tooth Contact Patterns”

procedure in this section.

앫 If the ring gear runout exceeds the specification:

Remove the differential and ring gear assembly from the

carrier.

A. Inspect the differential parts, including the carrier, for

wear and damage. Repair or replace parts as necessary.

B. Install the main differential case and ring gear assembly

into the carrier. Refer to the procedure in this section.

C. Repeat the procedure for preload adjustment of the

differential side bearings.

4. Once the adjustments are complete, tighten the bearing cap

capscrews as follows.

앫 Flange side bearing cap capscrews: Tighten to

320-400 lb-ft (430-540 N폷m).

@

앫 Plain half side bearing cap capscrews: Tighten to

200-258 lb-ft (270-350 N폷m).

@

5. Once all adjustments are complete, install the capscrews and

washers that hold the two bearing adjusting rings in position.

Use the following procedure.

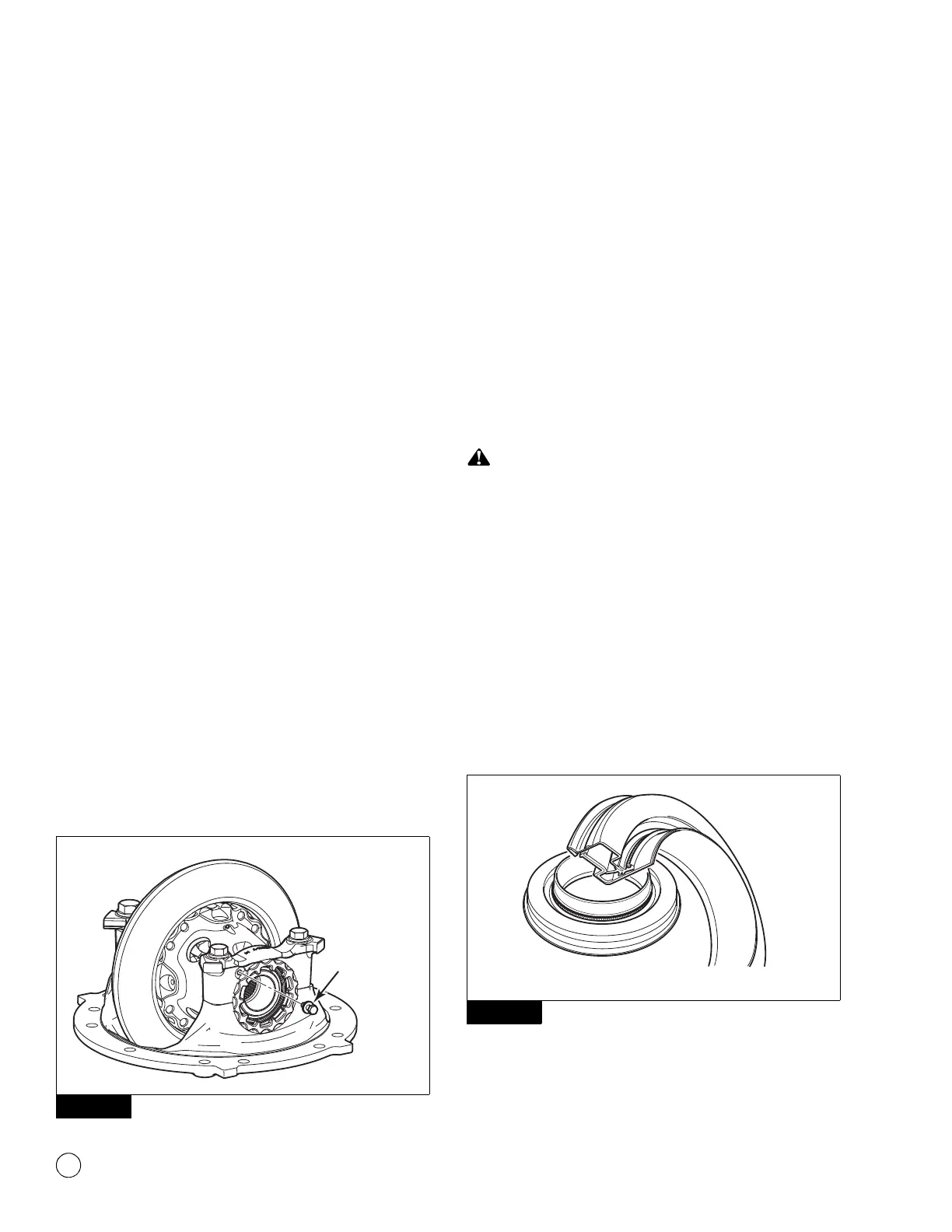

A. On each bearing cap, install two capscrews and washers

in the holes on the bearing cap so that the capscrews are

between the lugs of the adjusting ring. New capscrews

include a locking patch, which can only be used once. If

you are installing used capscrews, apply Loctite

242

threadlocker to the capscrew threads before installing the

capscrews. Figure 5.66.

Figure 5.66

B. Tighten the adjusting ring capscrews to 22-30 lb-ft

(30-40 N폷m).

@

Installation

Unitized Pinion Seal and Yoke

1. Remove the old seal. Do not damage the seal area of the

carrier. Do not touch or allow dirt or grease to contaminate the

sealing surface areas or the adjacent bearings.

2. Inspect the seal area of the carrier for damage that could

cause lubricant leaks after you install the seal. Use emery

paper or an equivalent product to remove scratches, nicks or

burrs only.

Inspect the axle breather for contaminants, such as dirt,

lubrication or debris, which can cause pressure to build inside

the axle. Damage to the seal and premature seal lip wear can

result. Remove the axle breather. Use a safe cleaning solvent

to clean the inside and outside of the breather.

3. Inspect the axle breather for contaminants, such as dirt,

lubrication or debris.

앫 If you find contaminants in the axle breather: Remove

the axle breather. Use a safe cleaning solvent to clean the

inside and outside of the breather.

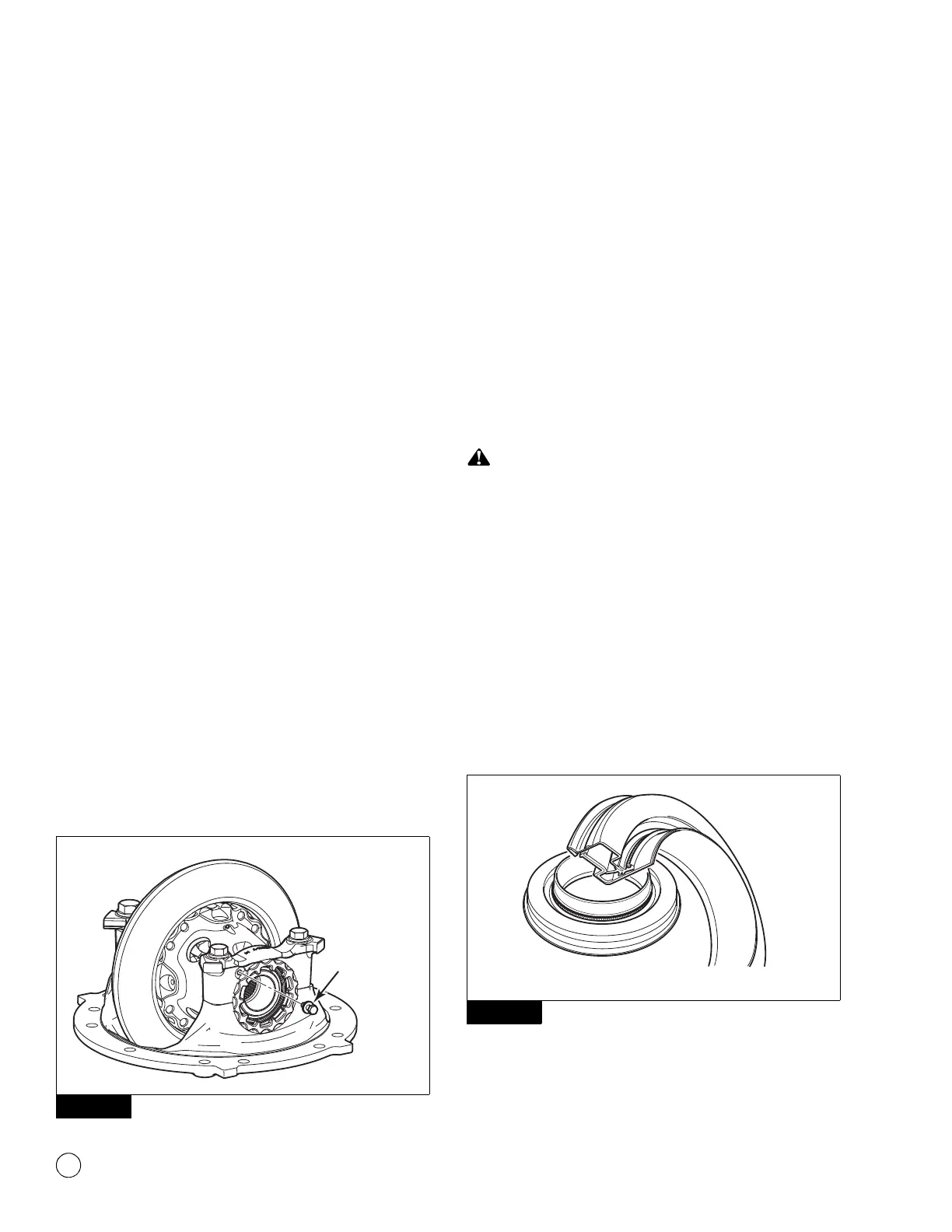

4. Remove the replacement unitized seal from the package.

Figure 5.67.

Figure 5.67

Figure 5.66

4011961a

CAPSCREW

AND

WASHER

Figure 5.67

4005523a

Loading...

Loading...