5 Assembly and Installation

27

Meritor Maintenance Manual MM-15103 (Issued 07-17)

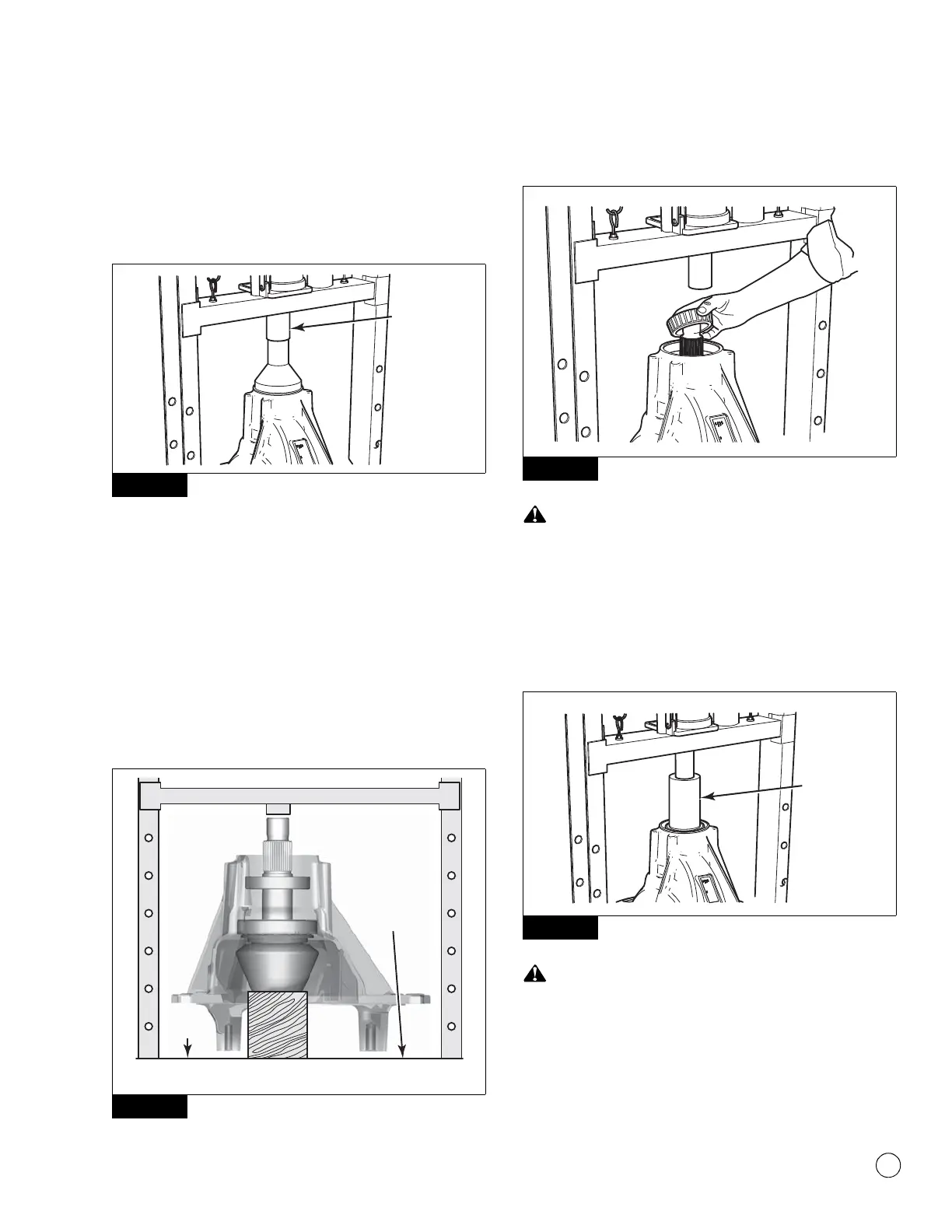

C. Use a sleeve or a bearing driver tool and a press to install

the cup. Press the cup into the carrier until the bottom of

the cup touches the bottom of the bore. If a press is not

available, use a sleeve, a brass drift or a bearing driver

tool and a hammer to install the cup. Figure 5.7.

Figure 5.7

Installation

Drive Pinion

1. Place the drive pinion into the carrier so that the pinion is

through the inner and the outer bearing cups.

2. Place the carrier into a press so that the legs of the carrier are

toward the BOTTOM of the press. Place a support such as a

block of wood under the head of the drive pinion so that the

inner bearing cone on the pinion shaft touches the inner

bearing cup in the carrier. Do not allow the carrier to contact

the surface of the press. Figure 5.8.

Figure 5.8

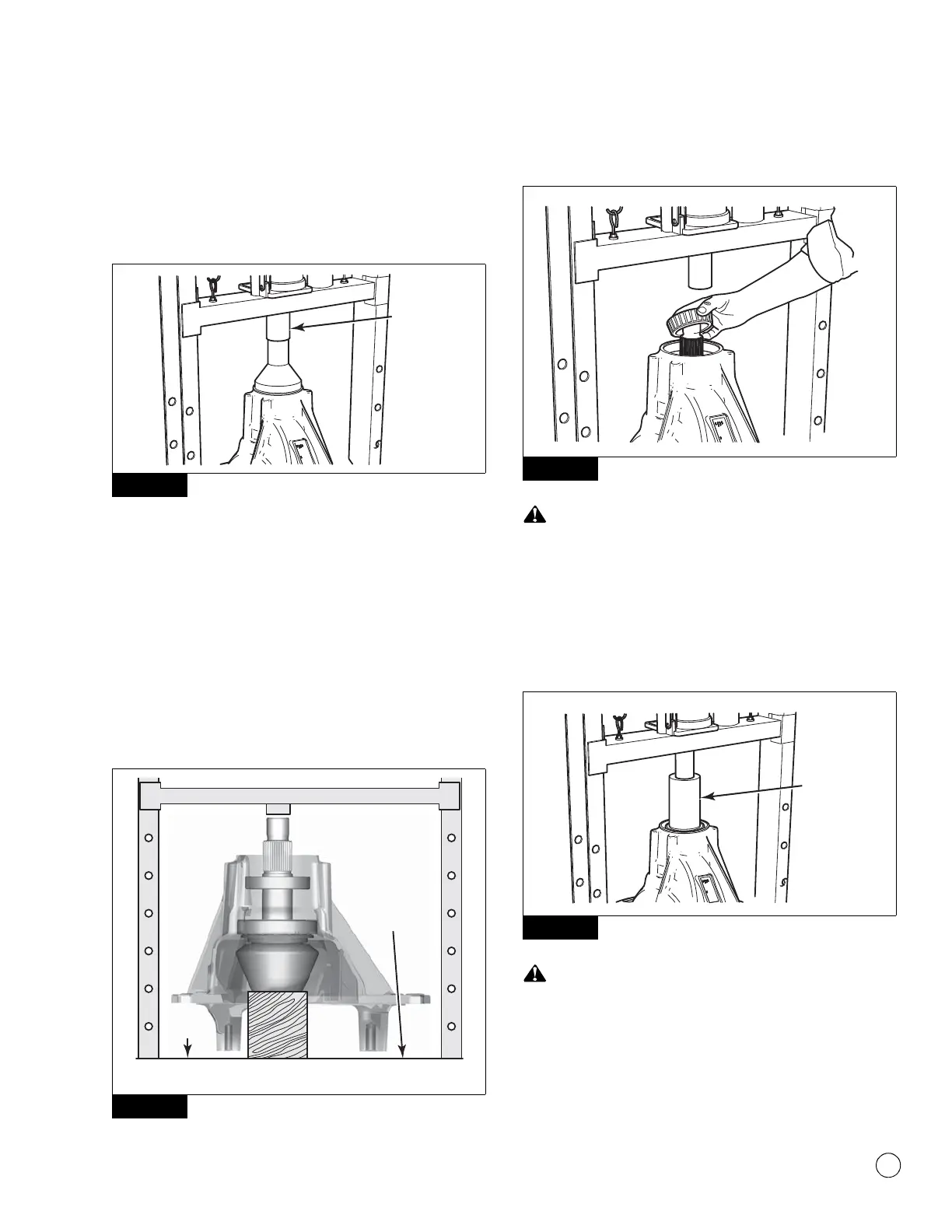

3. Place the outer bearing cone onto the pinion shaft. Figure 5.9.

Figure 5.9

Do not use excessive press load when you install the outer

pinion cone during the “dry fit” assembly procedure. Damage

to the bearings can result.

4. Use a press and a sleeve to install the outer bearing cone onto

the pinion. Apply no more than two tons (1814 kg) of force to

verify that the bearing cone is correctly installed. Figure 5.10.

Figure 5.10

Do not use excessive pinion nut torque during the “dry fit”

assembly procedure. Damage to the bearings can result.

5. Install the drive pinion nut to contact the bearings while

allowing free movement of the pinion.

Figure 5.7

Figure 5.8

4011978c

Carrier should

not touch

the surface

of the press.

BLOCK OF WOOD

SUPPORTING PINION

PRESS

SURFACE

Figure 5.9

Figure 5.10

4011980a

SLEEVE

Loading...

Loading...