5 Assembly and Installation

32

Meritor Maintenance Manual MM-15103 (Issued 07-17)

앫 If the torque value exceeds 10 lb-ft (13.6 N폷m):

Disassemble the differential gears from the case halves.

Inspect the case halves, spider, gears and thrust washers.

Repair or replace parts. Assemble the parts and repeat Step

2 through Step 4.

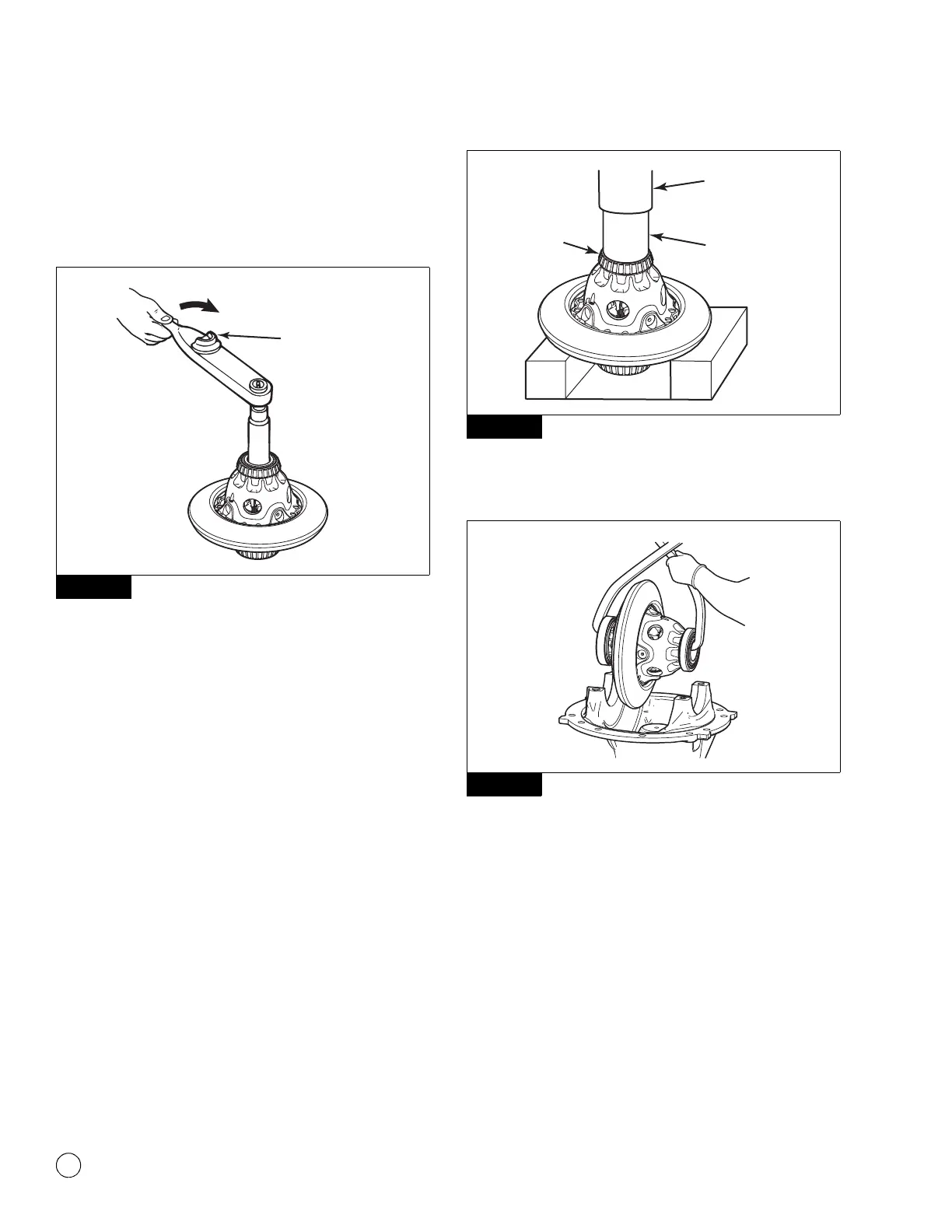

Figure 5.27

Installation

“Dry Fit” Installation of the Main Differential

Case and Ring Gear Assembly Into the

Carrier

To carry out preliminary checks for drive pinion adjustments,

perform a “dry fit” installation of the differential and ring gear

assembly. Do not lubricate, apply sealant or tighten the fasteners

completely. Once adjustments are made, perform the “final”

installation steps to complete the procedure.

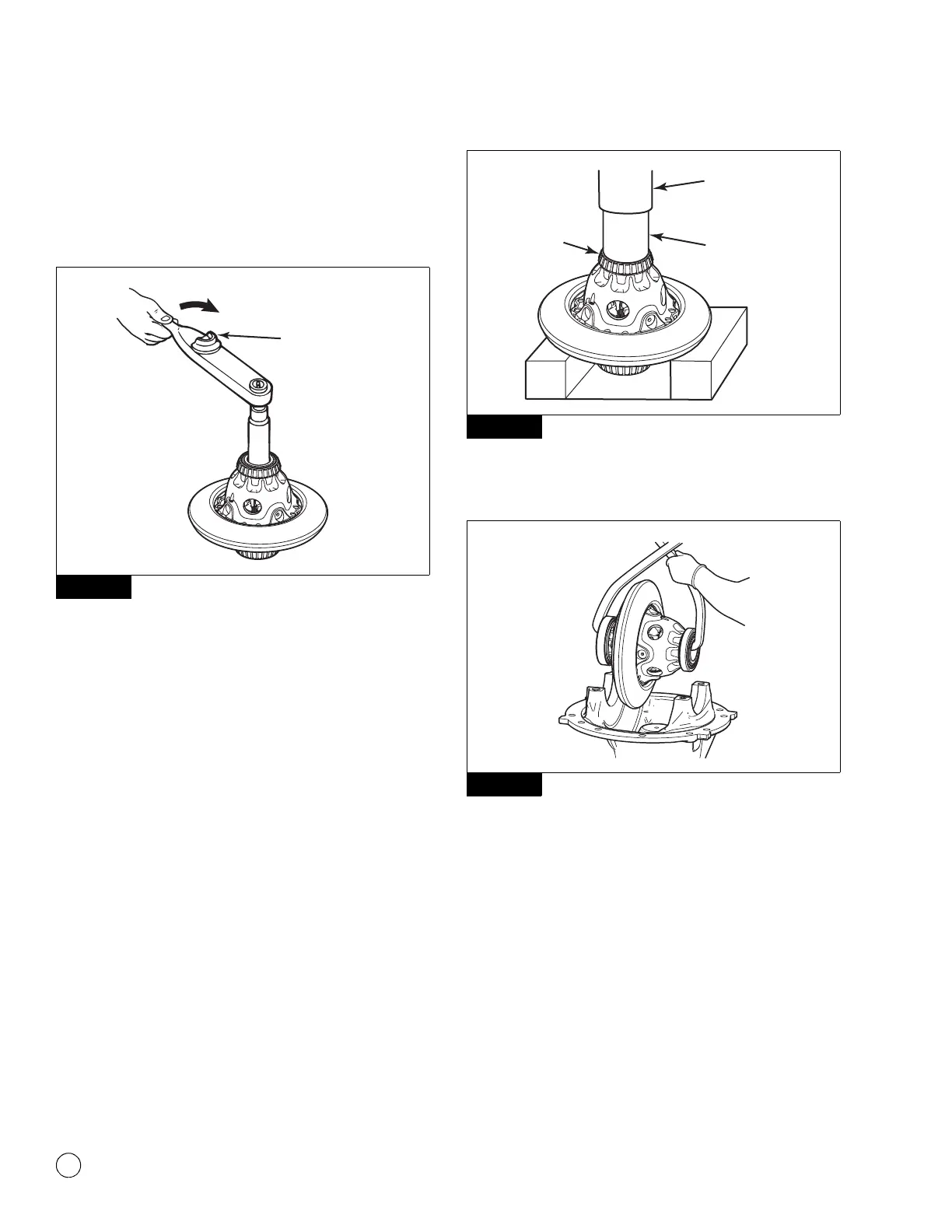

1. If the bearing cones on the main differential case were

removed, install a new cone and cup in a fully-matched set

from the same manufacturer. Bearing cups and cones from

different manufacturers are not interchangeable. Use a press

and sleeve to install the cones onto the case. Press only on the

inner race of the bearing. Figure 5.28.

Figure 5.28

2. Install the bearing cups over the bearing cones on the case

halves. Figure 5.29.

Figure 5.29

3. Use a lifting device to safely lift the differential and ring gear

assembly and install it into the carrier. The bearing cups must

be flat against the bores between the carrier legs. Figure 5.29.

4. Install the bearing adjusting rings between the carrier legs.

Figure 5.30.

Figure 5.27

Read torque

value.

4012322a

Figure 5.28

Figure 5.29

PRESS

SLEEVE

BEARING

CONE

4012323a

4011964a

Loading...

Loading...