5 Assembly and Installation

38

Meritor Maintenance Manual MM-15103 (Issued 07-17)

Figure 5.50

6. If the backlash and contact patterns are correct, remove the

leg cap capscrews. Use an appropriate lifting device to remove

the ring gear.

Installation

“Final” Installation of the Drive Pinion and

Bearing Preload Adjustment

Use the shim pack and backlash established by the “dry fit”

procedure for final assembly.

The preload of the bearings on the drive pinion is controlled by a

variable spacer behind the outer bearing cone.

Adjust the preload by changing the size of the spacer.

앫 To decrease the preload: Use a thicker spacer.

앫 To increase the preload: Use a thinner spacer.

If the depth of the drive pinion is changed, the thickness of the

spacer must also be changed the same amount. Refer to the

following examples.

앫 If a 0.003-inch (0.076 mm) shim is ADDED to the shim pack

to INCREASE the depth of the drive pinion: A 0.003-inch

(0.076 mm) larger spacer must be installed to keep the preload

on the bearings.

앫 If a 0.003-inch (0.076-mm) shim is REMOVED from the shim

pack to DECREASE the depth of the drive pinion: A

0.003-inch (0.076 mm) smaller spacer must be installed to keep

the preload on the bearings.

Install the Drive Pinion

1. Apply axle lubricant to the pinion bearing cups and cones.

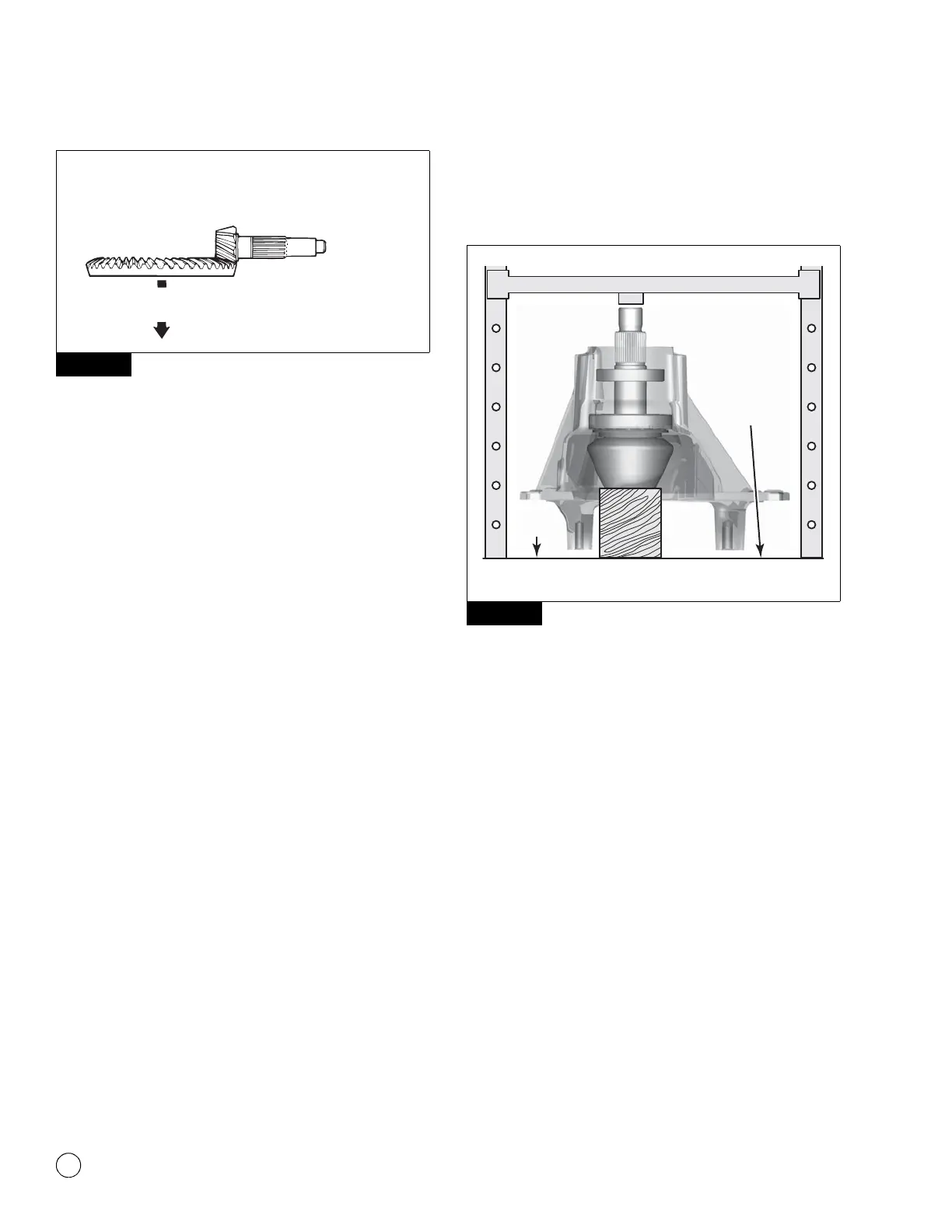

2. Place the carrier into a press. Figure 5.51.

Figure 5.51

3. Install the pinion shaft assembly into the carrier. Seat the inner

bearing cone fully against the inner bearing cup. Figure 5.51.

4. Support the pinion shaft with blocks of wood so that the inner

bearing cone remains in contact with the inner bearing cup.

Figure 5.51.

5. Install the fixed spacer onto the pinion stem.

6. Install the variable spacer onto the pinion stem. If the depth of

the drive pinion has increased or decreased, select a variable

spacer with the same change in thickness. Figure 5.52.

Figure 5.50

Increase.

backlash.

Move pattern toward

toe, tighten adjusting

ring this side.

Loosen adjusting

ring this side.

1002805b

Figure 5.51

4011978c

Carrier should

not touch

the surface

of the press.

BLOCK OF WOOD

SUPPORTING PINION

PRESS

SURFACE

Loading...

Loading...