5 Assembly and Installation

37

Meritor Maintenance Manual MM-15103 (Issued 07-17)

Figure 5.46

4. Change the thickness of the shim pack under the inner pinion

bearing cup to move the contact patterns between the top and

root of the gear teeth. Use the following procedure.

NOTE: If the shim pack is changed, the bearing preload must

be rechecked.

A. Remove the drive pinion, inner bearing cup and shims

from the carrier. Refer to Section 3.

앫 To correct a high-contact pattern: Increase the

thickness of the shim pack under the inner bearing

cup, which moves the drive pinion TOWARD the ring

gear. This also moves the convex contact pattern

towards the heel and concave pattern towards the toe.

Figure 5.38 and Figure 5.47.

앫 To correct a low-contact pattern: Decrease the

thickness of shim pack under the inner bearing cup,

which moves the drive pinion AWAY from the ring gear.

This also moves the convex contact pattern towards

the toe and concave pattern towards the heel.

Figure 5.48.

B. Install the drive pinion, inner bearing cup and shims into

the carrier. The pinion cone number can be either 100ths

of a millimeter or 1,000ths of an inch.

C. Repeat Step 1 through Step 4 until the contact patterns

are in the center between the top and bottom of the gear

teeth.

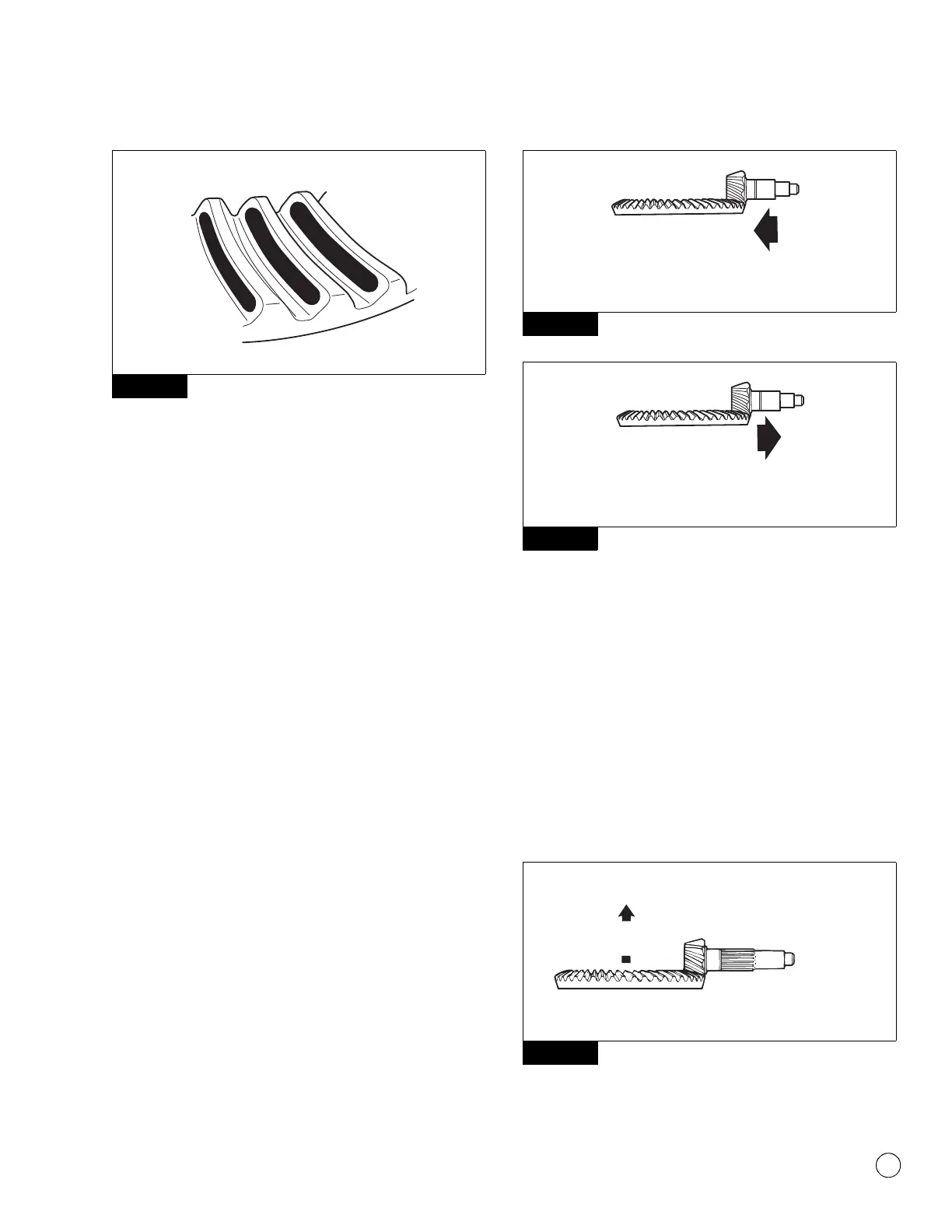

Figure 5.47

Figure 5.48

5. Adjust ring gear backlash within the correct specification to

move the contact patterns to the correct location in the length

of the gear teeth. Refer to Ring Gear Tooth Contact Pattern,

Backlash in this section.

A. Decrease the backlash to move the convex pattern toward

the toe and concave pattern toward the heel. Figure 5.49.

B. Increase the backlash to move the convex pattern toward

the heel and the concave pattern toward the toe.

Figure 5.50.

C. Repeat Step 1 through Step 3 and Step 5 until the contact

patterns are at the correct location in the length of the

gear teeth.

Figure 5.49

Figure 5.46

4008139a

SATISFACTORY PATTERN IN OPERATION

CONVEX

Figure 5.47

Figure 5.48

Figure 5.49

1003102f

Increase shim pack.

1003101f

Decrease shim pack.

Decrease

backlash.

Move pattern toward

toe, loosen adjusting

ring this side.

Tighten adjusting

ring this side.

1002804b

Loading...

Loading...