3 Removal and Disassembly

6

Meritor Maintenance Manual MM-15103 (Issued 07-17)

3 Rem oval and D isassembl y

Hazard Alert Messages

Read and observe all Warning and Caution hazard alert messages in

this publication. They provide information that can help prevent

serious personal injury, damage to components, or both.

To prevent serious eye injury, always wear safe eye protection

when you perform vehicle maintenance or service.

Park the vehicle on a level surface. Block the wheels to

prevent the vehicle from moving. Support the vehicle with

safety stands. Do not work under a vehicle supported only by

jacks. Jacks can slip and fall over. Serious personal injury and

damage to components can result.

Use a brass or synthetic mallet for assembly and disassembly

procedures. Do not hit steel parts with a steel hammer. Pieces

of a part can break off. Serious personal injury and damage to

components can result.

Removal

Fasteners Secured with Adhesive

If it’s difficult to remove fasteners secured with Dri-Loc

, Meritor

specification 2297-T-4180 or Loctite

277 adhesive, use the

following procedure.

When you remove fasteners secured with adhesive, slowly

heat the fastener to 350°F (177°C). Do not exceed this

temperature, or heat fasteners quickly. Damage to

components can result.

1. Heat a fastener for three to five seconds only. Try to loosen the

fastener with a wrench. Do not use an impact wrench or hit the

fastener with a hammer.

2. Repeat Step 1 until you can remove the fastener.

Axle Shafts

1. Wear safe eye protection.

2. Park the vehicle on a level surface and block the wheels to

prevent the vehicle from moving.

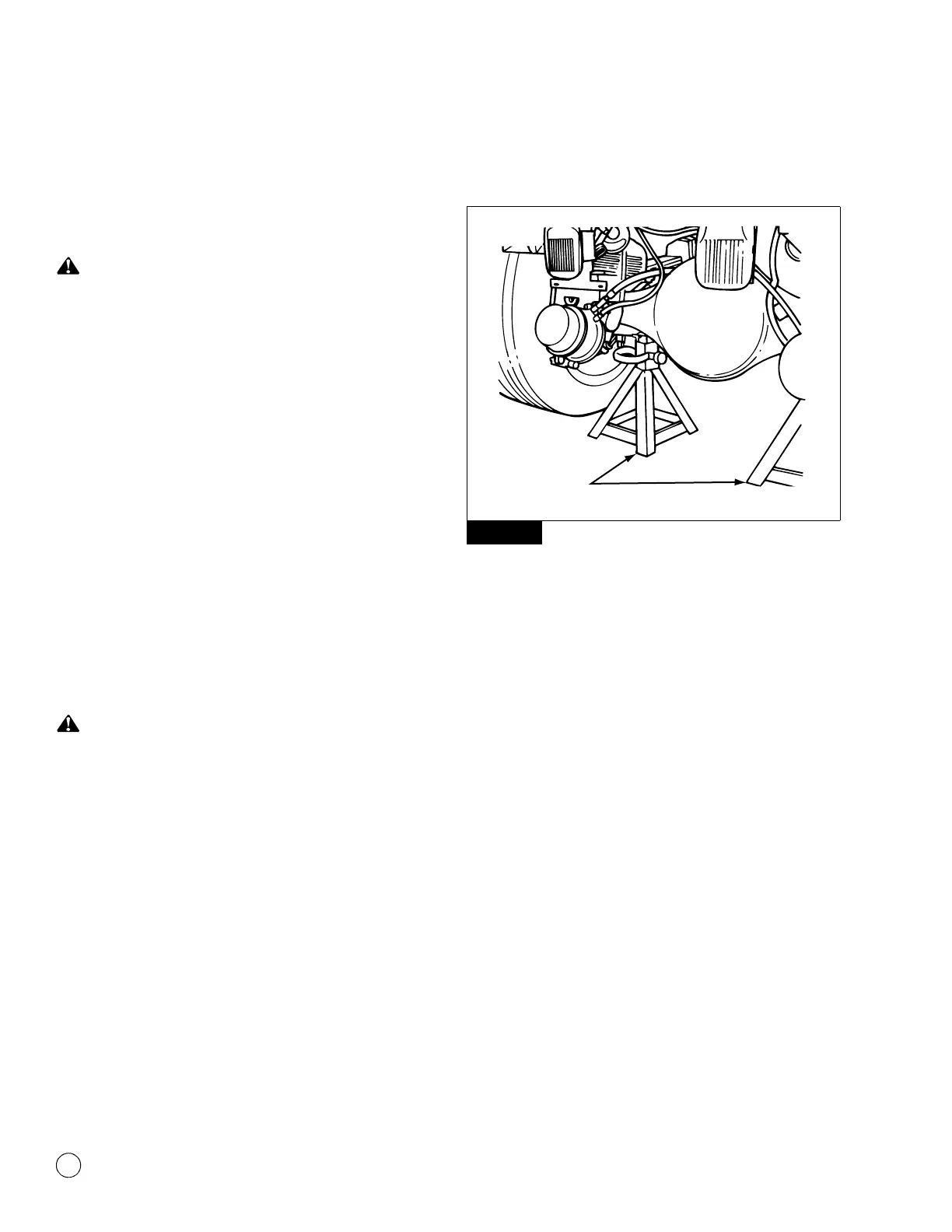

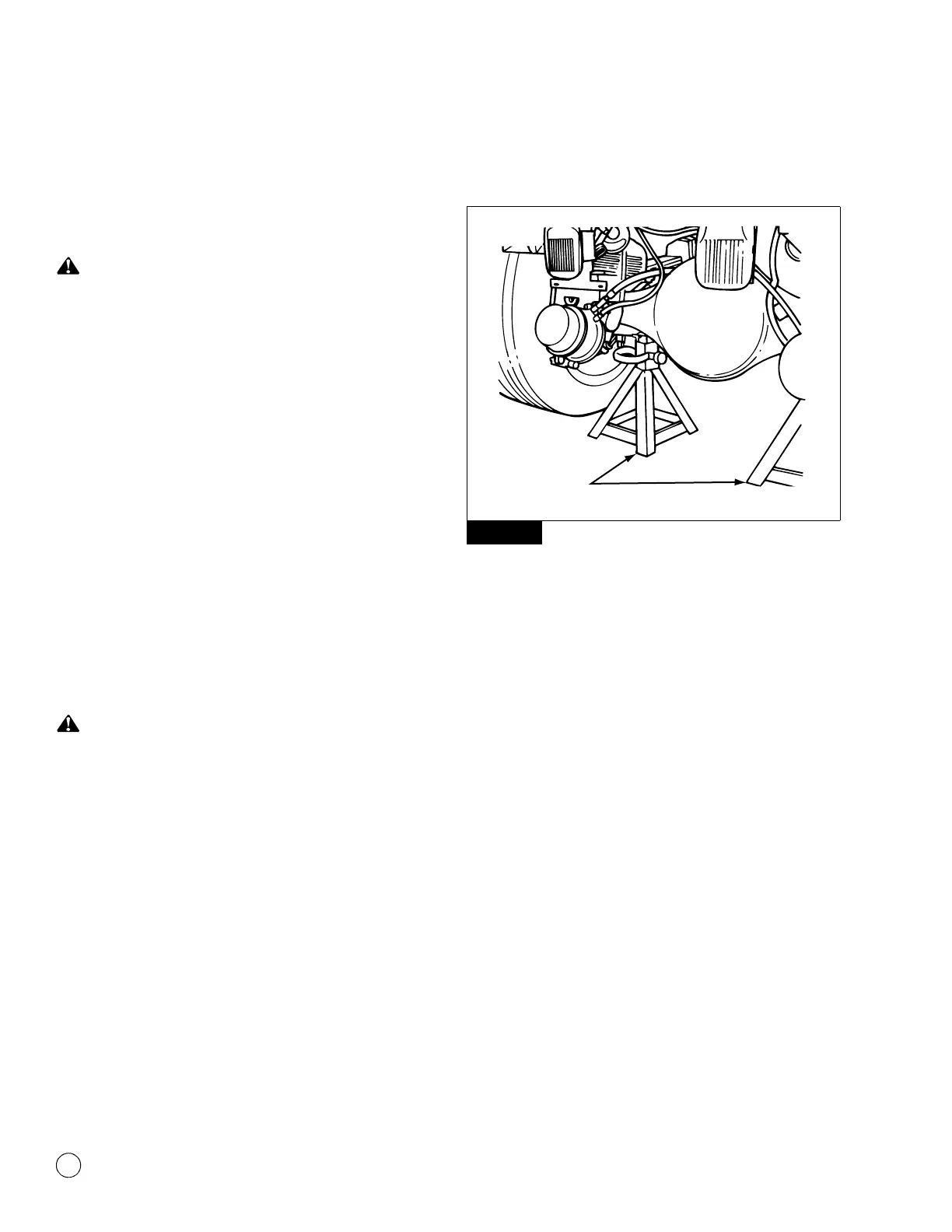

3. Raise the end of the vehicle where the axle is mounted. Use a

jack or other lifting tool, and place safety stands under each

side of the axle.

4. Place jackstands under each spring seat of the axle to hold the

vehicle in the raised position. Figure 3.1.

Figure 3.1

5. Remove the plug from the bottom of the axle housing and drain

the lubricant from the assembly.

6. Disconnect the driveline universal joint from the pinion input

yoke or flange on the carrier. Figure 3.2.

Figure 3.1

Loading...

Loading...