4 Prepare Parts for Assembly

17

Meritor Maintenance Manual MM-15103 (Issued 07-17)

Bearings

Use soft, clean paper or cloth rags to dry bearings immediately

after cleaning. Do not use compressed air, which can damage

the bearings when they are rotated and dried.

Use soft, clean paper or cloth rags to dry bearings immediately after

cleaning. Do not use compressed air.

Corrosion Protection

Prevent Corrosion on Cleaned Parts

1. Apply axle lubricant to cleaned and dried parts that are not

damaged and are to be assembled.

2. To store parts, apply a special material that prevents corrosion

to all surfaces. Wrap cleaned parts in a special paper that will

protect the parts from moisture and prevent corrosion.

Inspection

Inspect Parts

It is very important to inspect all parts carefully and completely

before the axle or carrier is assembled. Check all parts for wear and

replace damaged parts.

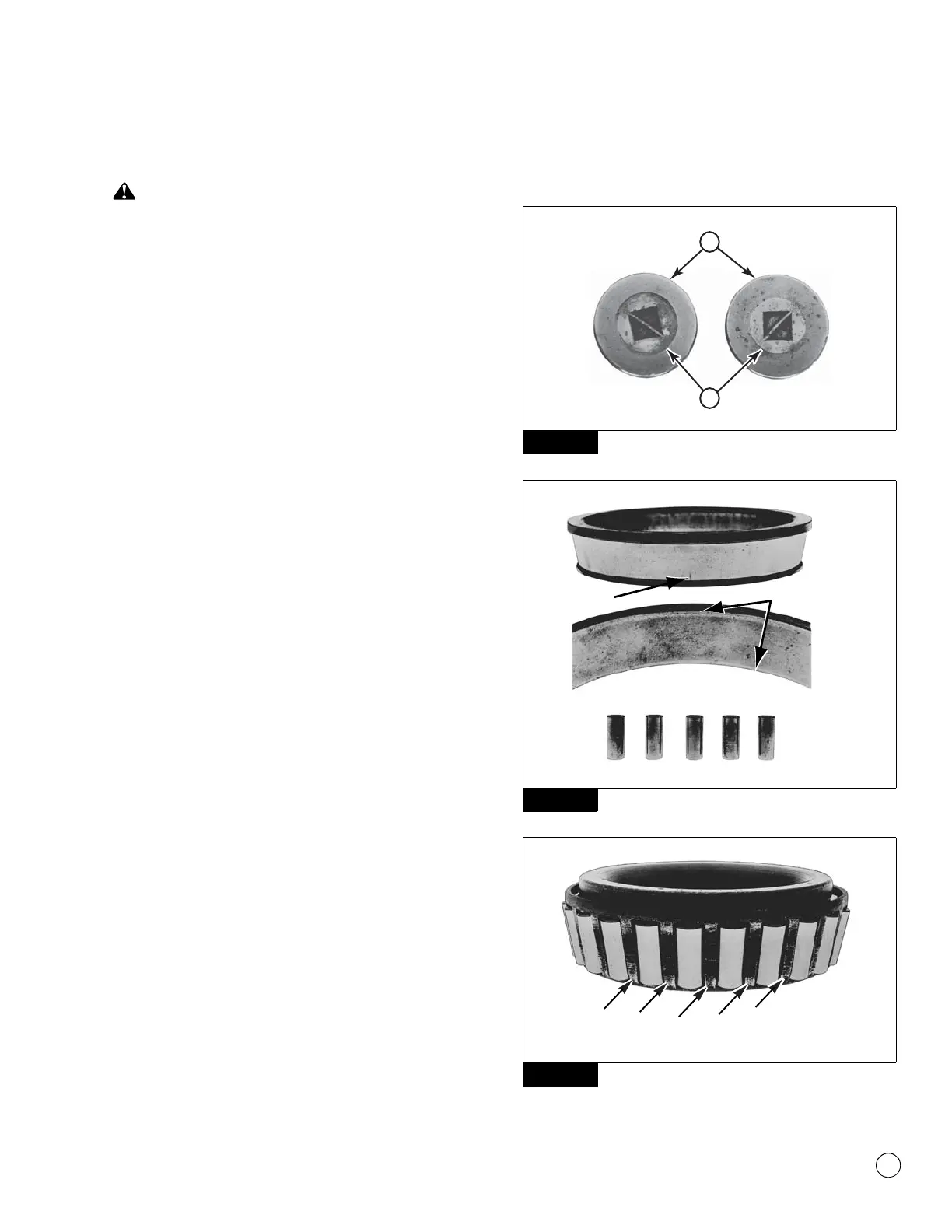

1. Inspect the cup, cone, rollers and cage of all tapered roller

bearings in the assembly. If any of the following conditions

exist, replace the bearing.

앫 The outer ring of the large-diameter end of the rollers is

worn level with or below the center surface. Figure 4.1.

앫 The radius at the large-diameter end of the rollers is worn

to a sharp edge. Figure 4.1.

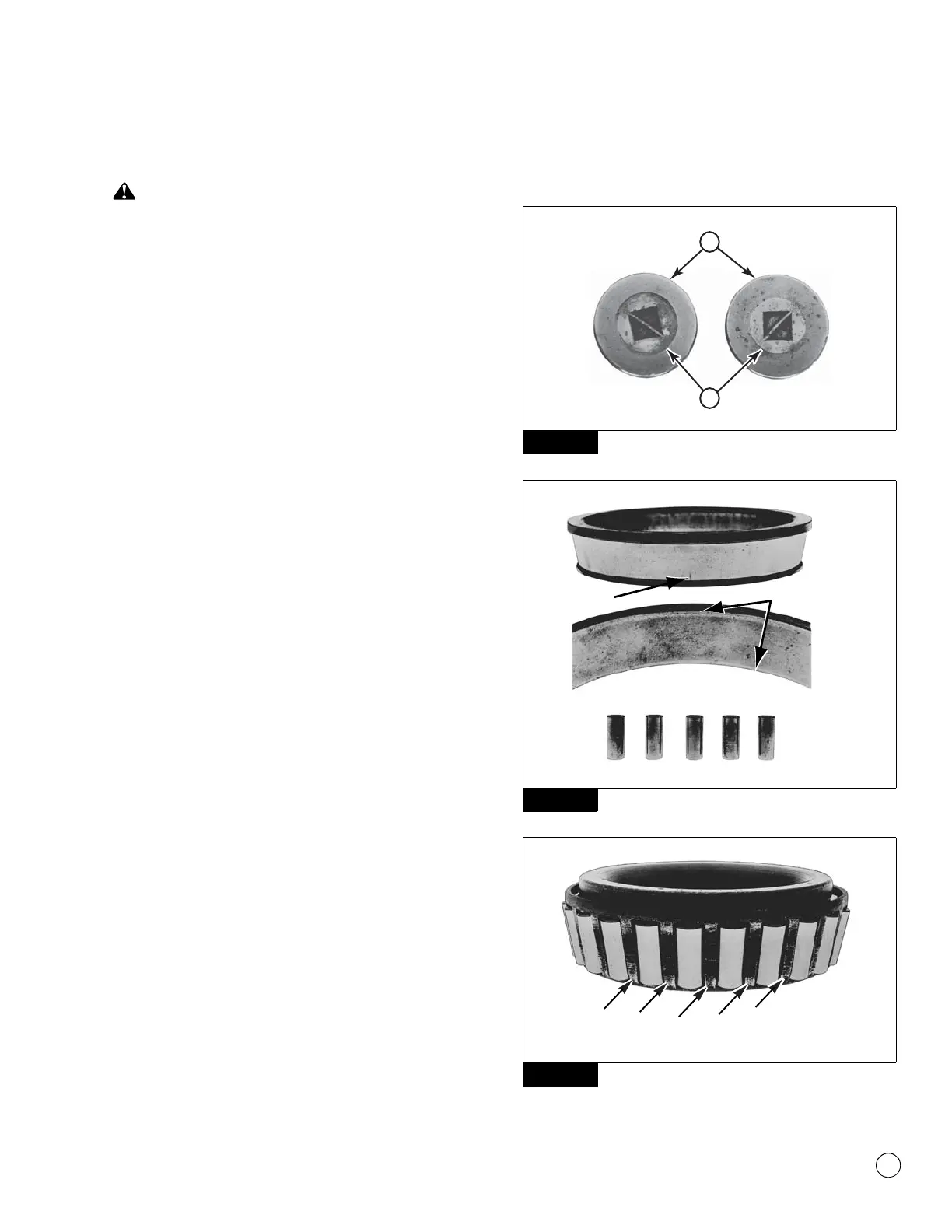

앫 There is a visible roller groove in the cup or cone inner race

surfaces. The groove can be seen at the small- or

large-diameter end of both parts. Figure 4.2.

앫 There are deep cracks or breaks in the cup, cone inner race

or roller surfaces. Figure 4.2.

앫 There are bright wear marks on the outer surface of the

roller cage. Figure 4.3.

앫 There is damage on the rollers and on the surfaces of the

cup and cone inner race that touch the rollers. Figure 4.4.

앫 There is damage on the cup and cone inner race surfaces

that touch the rollers. Figure 4.5.

Figure 4.1

Figure 4.2

Figure 4.3

Figure 4.1

Figure 4.2

Figure 4.3

1

2

1003017c

Loading...

Loading...