3 Removal and Disassembly

9

Meritor Maintenance Manual MM-15103 (Issued 07-17)

When you use a pry bar, be careful not to damage the carrier

or housing flange. Damage to these surfaces will cause oil

leaks.

6. Carefully remove the carrier from the axle housing using the

hydraulic roller jack. Use a pry bar that has a round end to help

remove the carrier from the housing. Take care that you don’t

damage the carrier or housing flange with the pry bar.

NOTE: A carrier stand is available from SPX Kent-Moore. To obtain

this tool, refer to the Service Notes page on the front inside cover of

this manual.

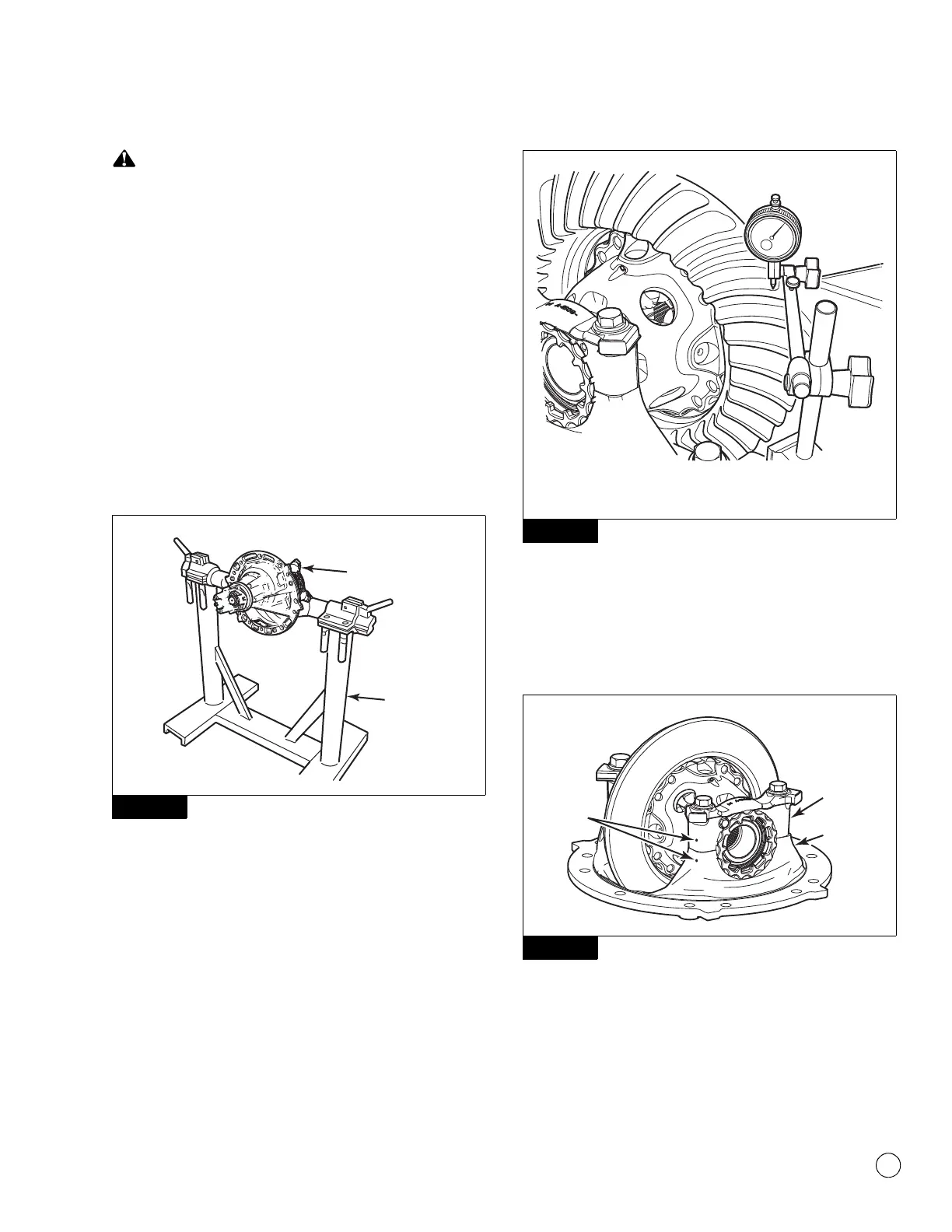

7. Use a lifting tool to lift the differential carrier by the input yoke

or flange. Do not lift the carrier by hand. Place the assembly in

a carrier stand. Figure 3.7. Refer to Section 9 to build a stand.

Figure 3.7

Differential and Ring Gear from the Carrier

1. Before you begin service procedures on the differential carrier,

inspect the gear set for damage.

앫 If the gear set isn’t damaged: You can reuse the gear set.

앫 If the gear set is damaged: Replace it with a new gear

set.

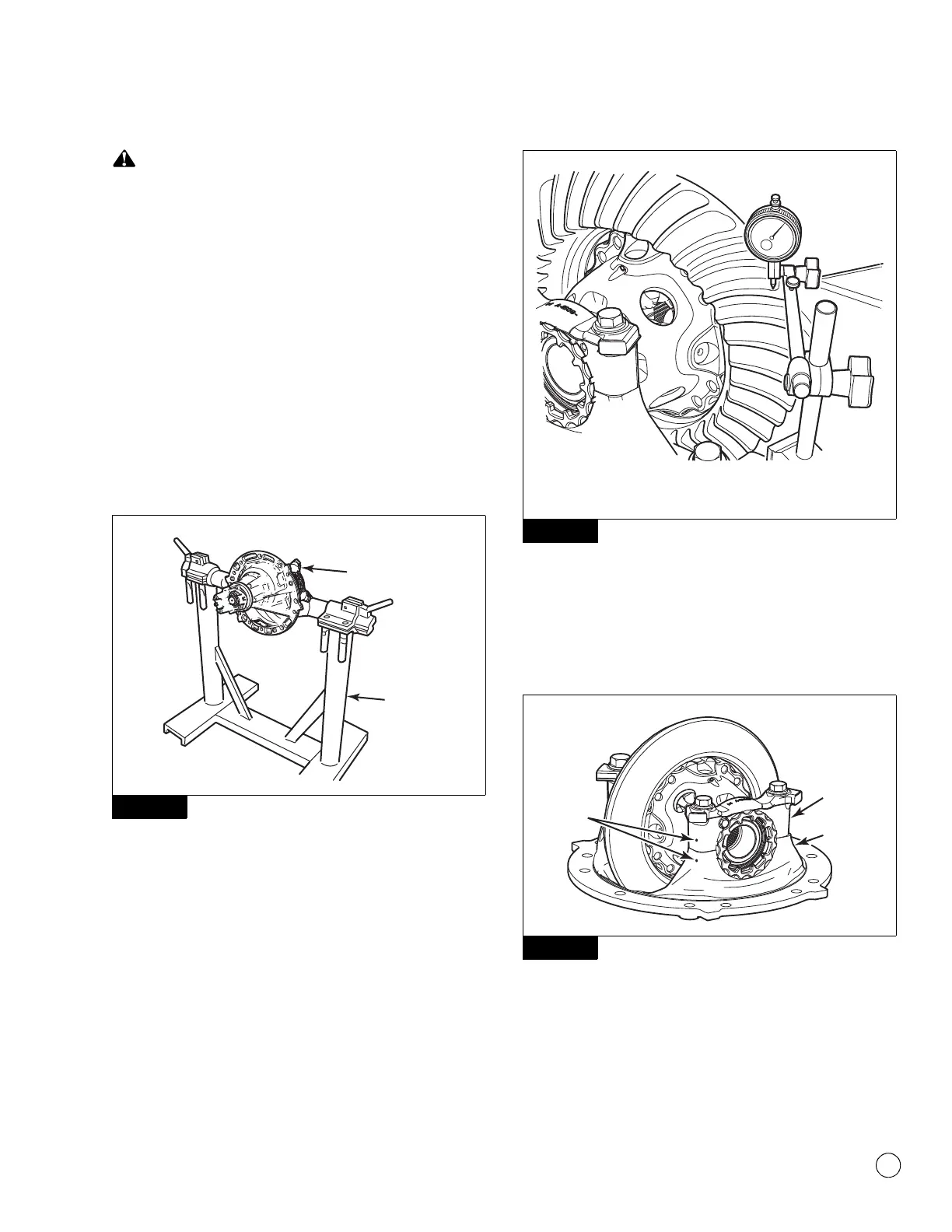

2. Measure and record gear set backlash. Figure 3.8. Refer to

Step 1 through Step 4 under Ring Gear Tooth Contact Pattern,

Backlash in Section 5 for instructions. Adjust backlash to the

original dimension when you install the gear set into the carrier

during assembly procedures.

Figure 3.8

3. Rotate the differential carrier in the repair stand until the ring

gear is at the TOP of the assembly.

4. Use a center punch and hammer to mark one carrier leg and

bearing cap to correctly match the parts during carrier

assembly. Figure 3.9.

Figure 3.9

5. Remove the capscrews and washers that secure the bearing

adjusting rings in position. Figure 3.10.

Figure 3.7

REPAIR

STAND

DIFFERENTIAL

CARRIER

4011957a

Figure 3.8

Figure 3.9

4011960a

CARRIER

CAP

CARRIER

LEG

MATCH

MARKS

Loading...

Loading...