5 Assembly and Installation

24

Meritor Maintenance Manual MM-15103 (Issued 07-17)

5 Assembly an d Installation

Hazard Alert Messages

Read and observe all Caution and Warning safety alerts below and

those that precede instructions or procedures you will perform.

To prevent serious eye injury, always wear safe eye protection

when you perform vehicle maintenance or service.

Take care when you use Loctite

adhesive to avoid serious

personal injury. Read the manufacturer’s instructions before

using this product. Follow the instructions carefully to prevent

irritation to the eyes and skin. If Loctite

adhesive material

gets into your eyes, follow the manufacturer’s emergency

procedures. Have your eyes checked by a physician as soon as

possible.

Observe all warnings and cautions provided by the press

manufacturer to avoid damage to components and serious

personal injury.

To avoid serious personal injury and damage to components,

take care when using lifting devices during service and

maintenance procedures. Inspect a lifting strap to ensure that

it is not damaged. Do not subject the lifting straps to shocks or

drop-loading.

Installation

“Dry Fit” and “Final” Assembly and

Installation Procedures

Correct assembly of the carrier requires a “dry fit” installation of the

drive pinion and ring gear to determine the correct drive pinion shim

pack thickness. The carrier is then disassembled and reassembled

using the spacers and adjusted shim pack. If the drive pinion is

correctly adjusted, perform the “final” installation steps to complete

the installation.

Installing the Drive Pinion, Adjusting Pinion

Depth and Contact Pattern

The procedure in this manual is to perform a “dry fit” installation of

the pinion, bearings and calculated shim pack into the case

WITHOUT the two spacers. You must also install the ring gear and

set the backlash to 0.012-inch (0.3 mm). After you check and

adjust the tooth contact patterns to determine the correct pinion

position, remove the ring gear and drive pinion. You must then install

the drive pinion with the two spacers as well as the correct shims.

Once you’ve obtained the correct adjustments, continue a “final”

installation of the ring gear and adjust as necessary.

Drive Pinion Shim Pack Thickness

NOTE: If the original gear set and shim pack are being installed, go

to the “dry fit” drive pinion assembly procedure in this section. If the

pinion depth shims are misplaced during carrier repair, use

0.030-inch (0.76 mm) for the initial pinion position and continue to

the “dry fit” drive pinion assembly procedure in this section. In all

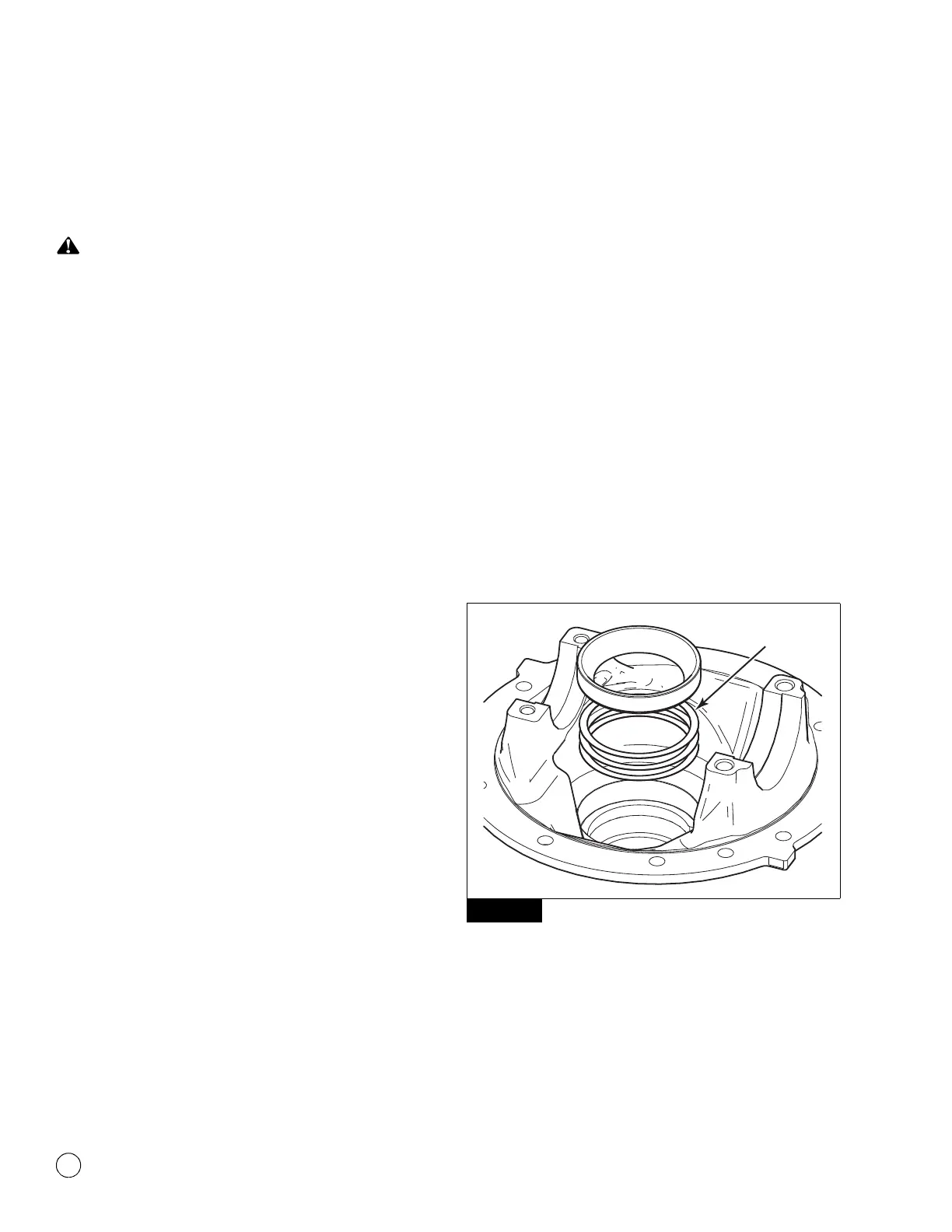

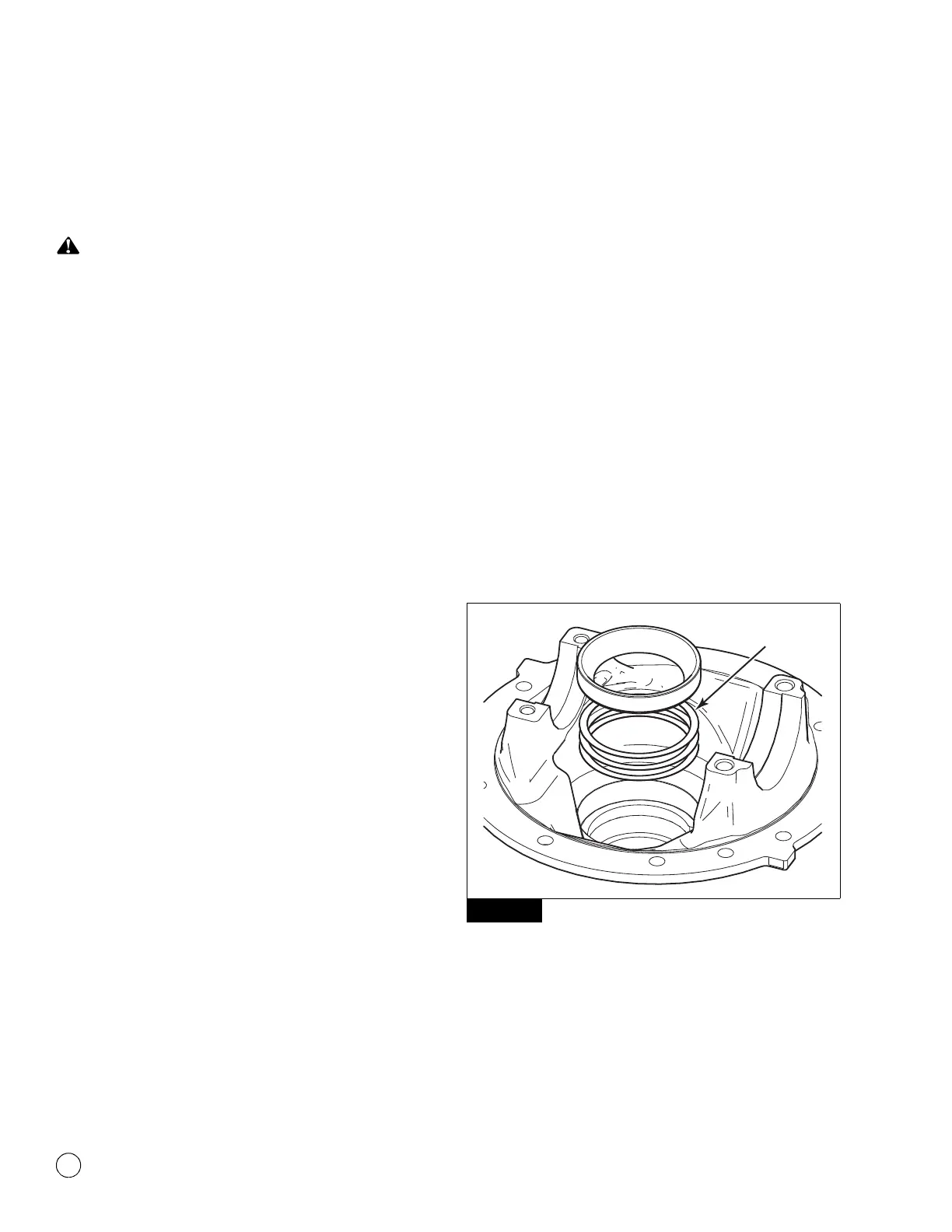

other cases, continue with the following procedure. Figure 5.1.

Figure 5.1

1. Use a micrometer to measure the thickness of the shim pack

that was removed from the differential carrier. Record the

measurement. Figure 5.2.

Figure 5.1

4011974a

SHIMS

Loading...

Loading...