5 Assembly and Installation

39

Meritor Maintenance Manual MM-15103 (Issued 07-17)

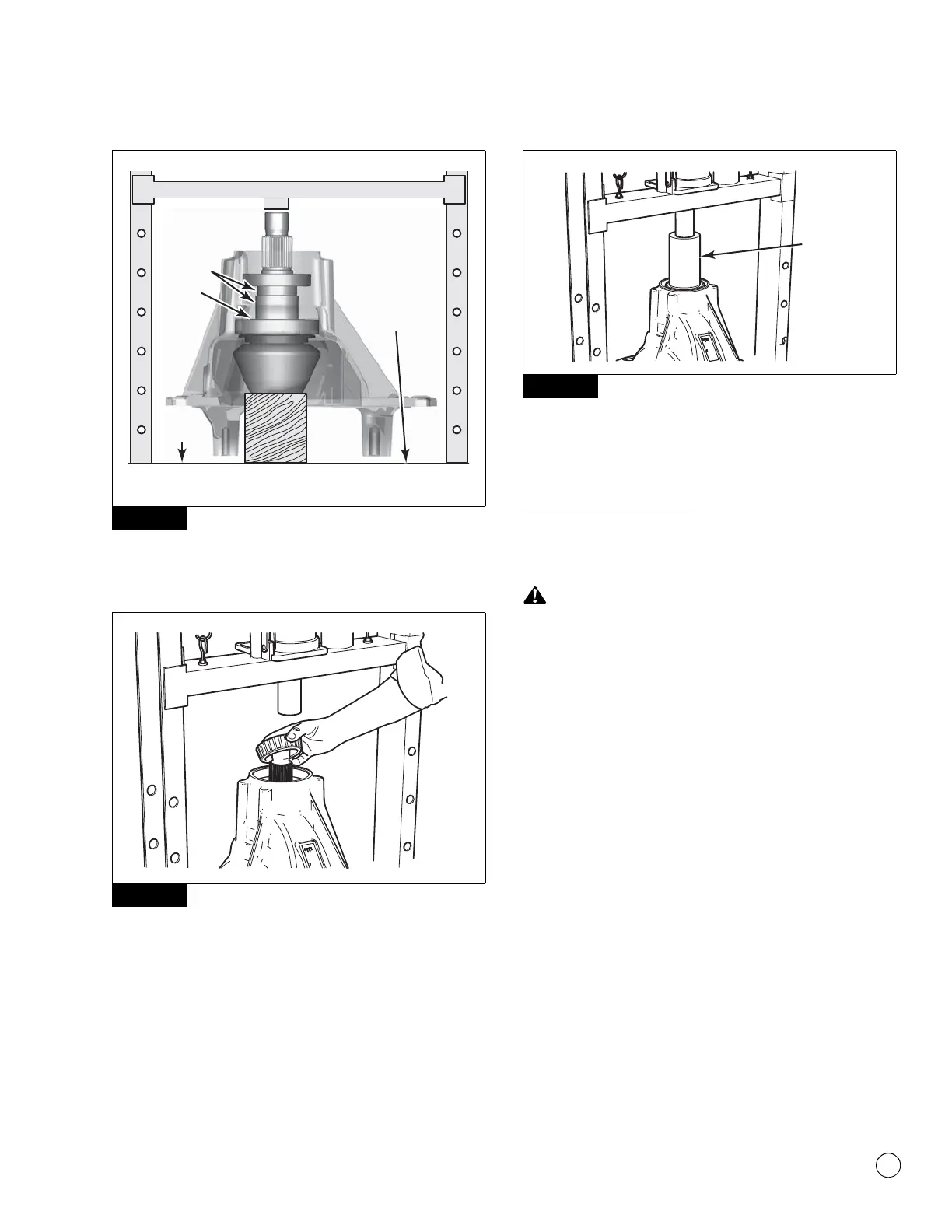

Figure 5.52

7. Install the outer bearing cone onto the pinion stem.

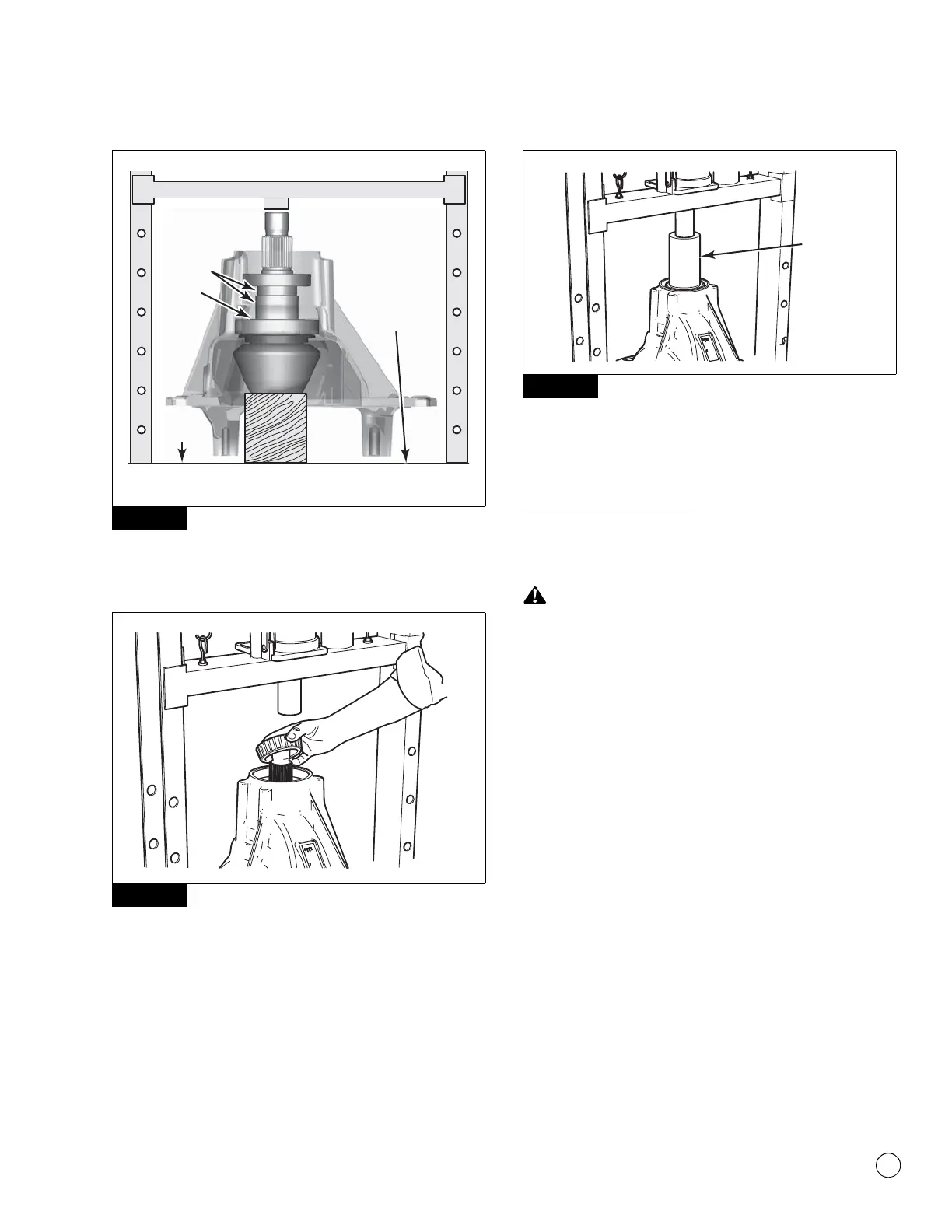

Figure 5.53.

Figure 5.53

8. Using a sleeve that is the same size as the bearing cone, press

the bearing onto the pinion shaft until it is fully seated in the

carrier. Figure 5.54.

Figure 5.54

Check Pinion Bearing Preload

Table C: Specifications

Do not install tight-fitting yokes or flanges on the shafts using

a hammer or mallet. A hammer or mallet will damage the yoke

or flange.

1. For the purpose of gauging preload, install a used yoke or

flange that fits loosely on the shaft. Do not install the intended

service yoke or flange for this procedure. Align the splines of

the test yoke or flange with the shaft splines. Slide the yoke or

flange over the shaft splines until seated.

2. Install the nut onto the drive pinion.

3. Fasten a yoke or flange bar to the input yoke or flange. The bar

will hold the drive pinion in position when the nut is tightened.

4. Tighten the nut onto the drive pinion to the correct torque

value. Refer to Table H in Section 7.

5. Remove the yoke bar.

6. Attach a torque wrench onto the drive pinion nut. Rotate the

drive pinion and read the value indicated on the torque wrench.

7. If the preload or torque of the pinion bearings is not within

specification, remove the drive pinion assembly from the

carrier. Replace the variable spacer to increase or decrease

preload. Refer to the procedure in this section. Repeat Steps 1

through Step 6 to recheck preload.

Figure 5.52

Figure 5.53

4011978b

Carrier should

not touch

the surface

of the press.

SPACERS

BLOCK OF WOOD

SUPPORTING PINION

SHIMS

PRESS

SURFACE

Figure 5.54

New pinion bearings 30-60 lb-in (3-6 N폷m)

Used pinion bearings in good

condition

20-50 lb-in (2.25-5.65 N폷m)

4011980a

SLEEVE

Loading...

Loading...