5 Assembly and Installation

45

Meritor Maintenance Manual MM-15103 (Issued 07-17)

If a yoke is removed after it has been partially or fully installed,

the unitized pinion seal will be damaged. Remove and discard

the original unitized pinion seal and replace it with a new one.

If a yoke has been installed into the unitized pinion seal and

then removed, the inner sleeve of the seal will be damaged.

Install a new seal.

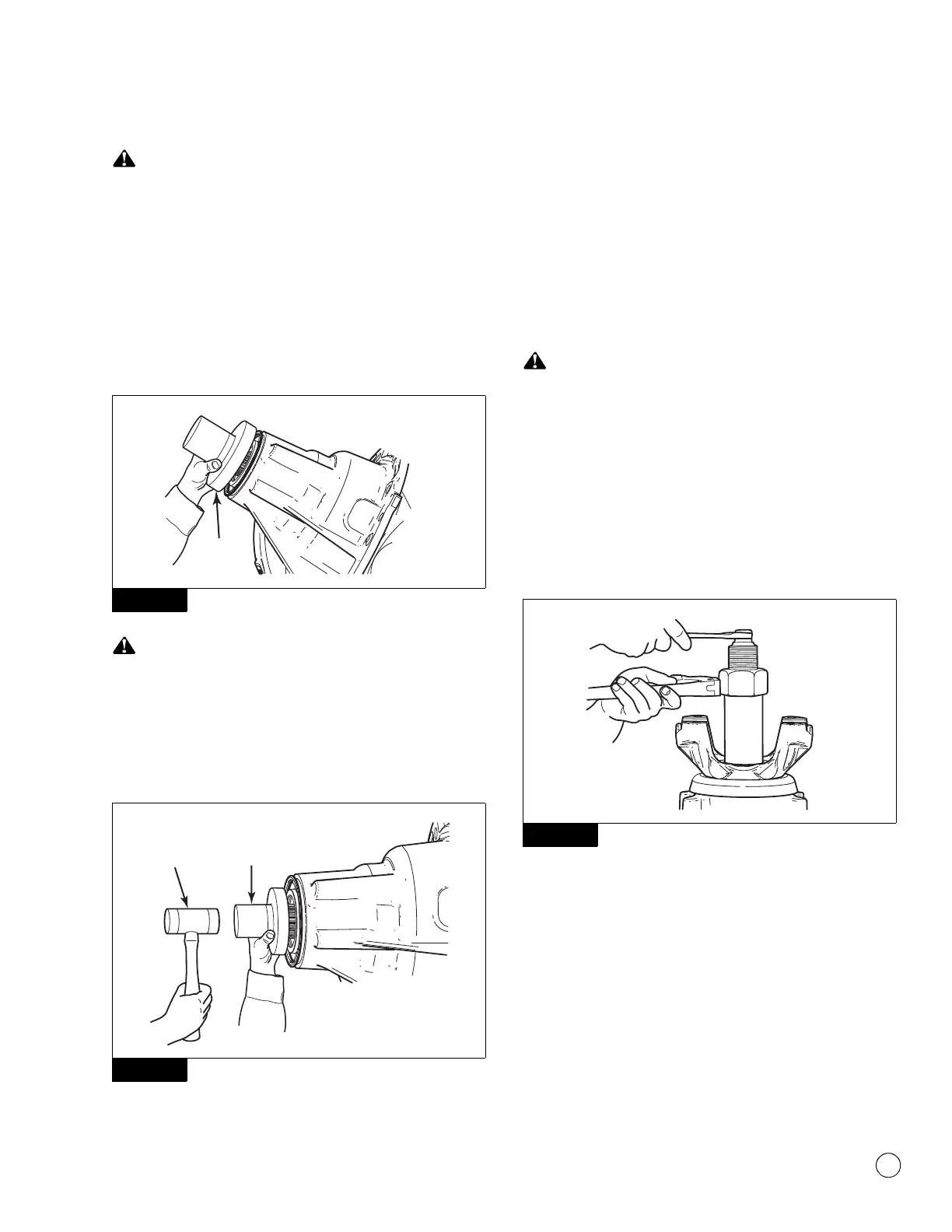

5. Place the seal, part number A1-1205Z2730, and seal driver,

tool number 2730T1, in position on the carrier. Figure 5.68.

Figure 5.68

Use a rubber mallet to install the seal. Do not use a steel, brass

or plastic hammer. Using a steel, brass or plastic hammer can

damage the seal and driver tool.

6. Use a rubber mallet to drive the seal into or against the carrier.

The seal must fully seat into or against the carrier. Figure 5.69.

Figure 5.69

7. Visually inspect the seal to verify that it is seated correctly.

8. Use a feeler gauge to check the seal gap. The seal is correctly

installed if the gap is less than 0.010-inch (0.25 mm) around

the circumference of the seal flange. If necessary, continue to

drive the seal in until the correct gap is obtained.

9. Apply clean axle lubricant around the end of the yoke or flange.

10. Align the yoke or flange splines with the shaft splines. Slide the

yoke or flange over the shaft splines.

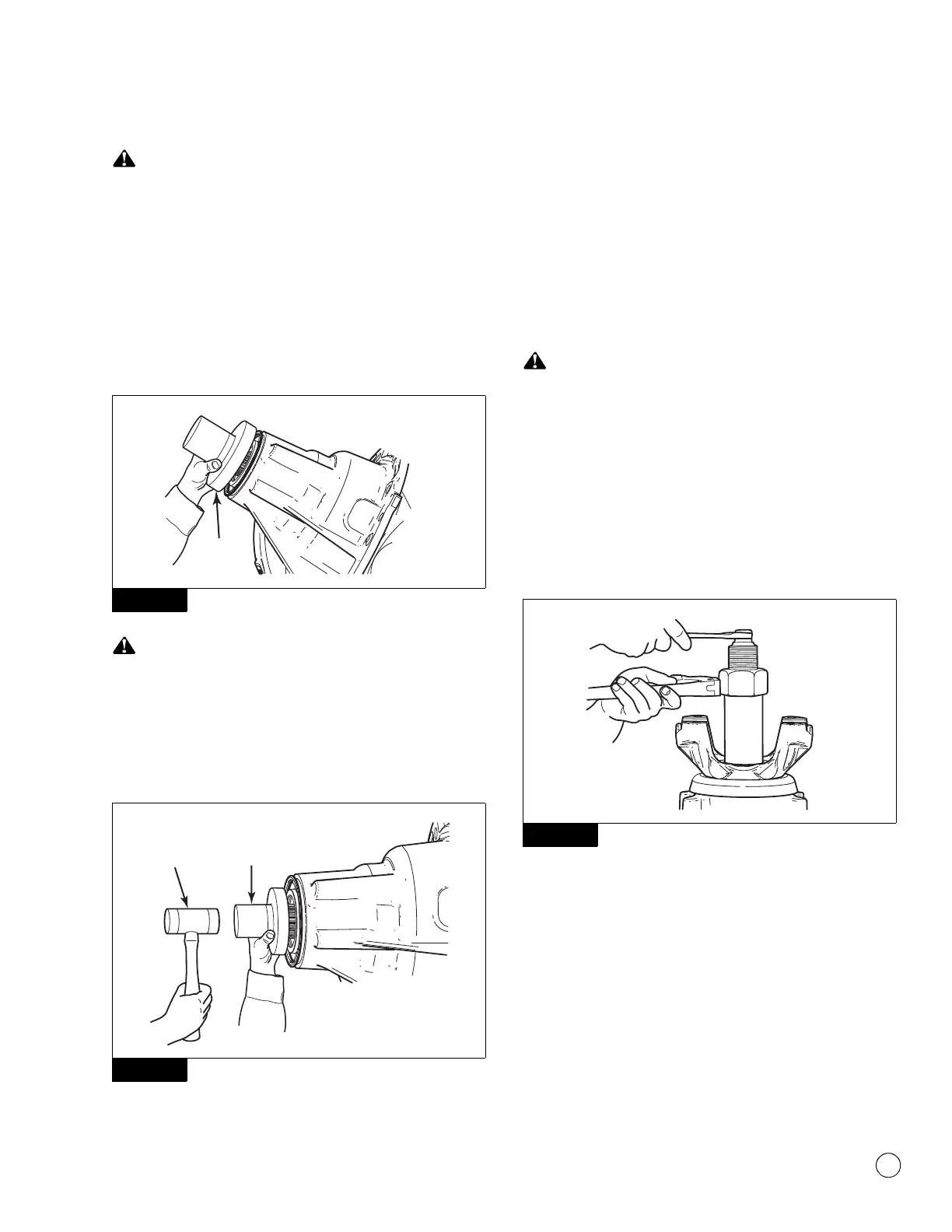

Use a press and a sleeve or yoke installation tool to install the

yoke or flange. Do not use a hammer or mallet. Using a

hammer or mallet can damage the bearings, yoke or flange.

11. Use a press and a sleeve or special yoke/flange driver tool,

Meritor part number MST-YT114, SPX Kent-Moore part

number J 48718, to install the yoke or flange. Do not use the

nut to draw on the yoke or flange. The yoke or flange must be

seated against the outer bearing. If a press and sleeve are

used, verify that the drive pinion is well supported. Figure 5.70.

Figure 5.70

12. Install the washer and nut onto the drive pinion.

13. Fasten a yoke or flange bar to the input yoke or flange. The bar

will hold the drive pinion in position when the nut is tightened.

Figure 5.71.

Figure 5.68

Figure 5.69

4012315a

SEAL

DRIVER

The seal must be fully

seated in or against

the carrier.

SEAL

DRIVER

RUBBER

MALLET

4012316a

Figure 5.70

4012317a

Loading...

Loading...