5 Assembly and Installation

42

Meritor Maintenance Manual MM-15103 (Issued 07-17)

When you turn the adjusting rings, always use a tool that

engages two or more opposite notches in the ring. An

adjusting ring tool can be used for this purpose. If the tool does

not correctly fit into the notches, damage to the lugs will occur.

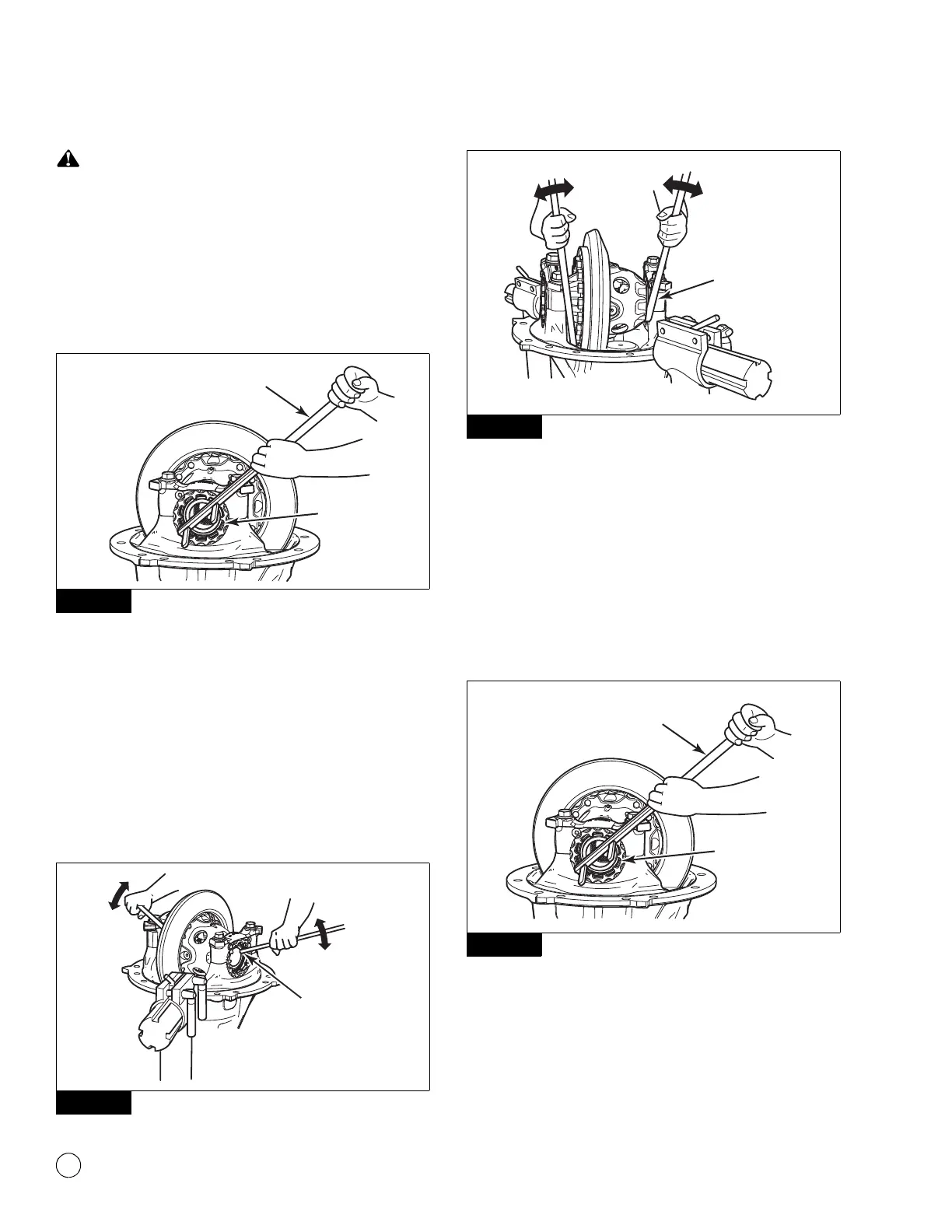

2. Use an adjusting ring tool to loosen the adjusting ring that is

opposite the ring gear. A small amount of end play will show on

the dial indicator. Figure 5.59.

Figure 5.59

3. Use one of the following methods to move the differential and

the ring gear carefully to the left and right while you read the

dial indicator.

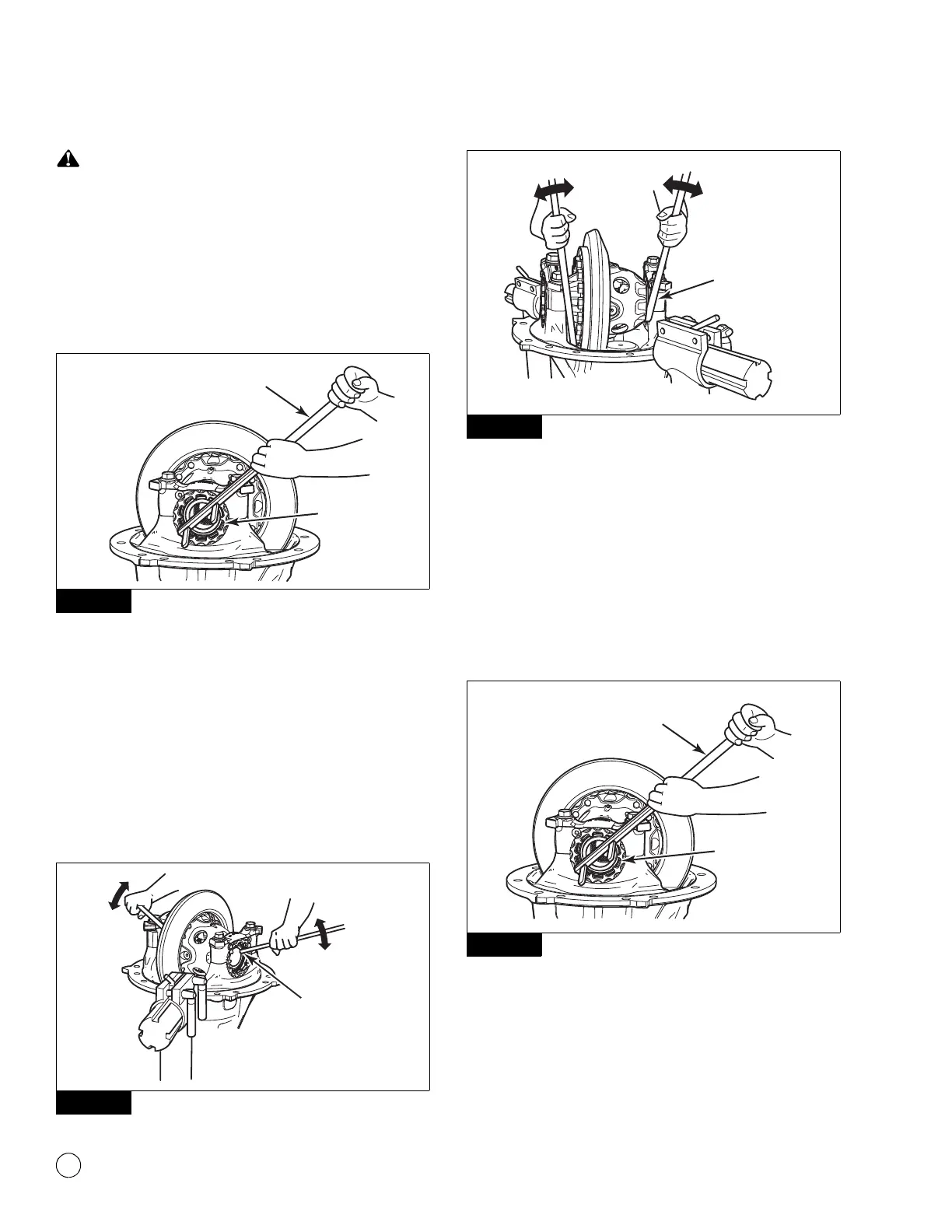

A. Insert two pry bars between the bearing adjusting rings

and the ends of the differential case. The pry bars must

not touch the differential bearings. Figure 5.60.

B. Insert two pry bars between the differential case or the

ring gear and the carrier at locations other than described

in Step A. The pry bars must not touch the differential

bearings. Figure 5.61.

Figure 5.60

Figure 5.61

4. Tighten the bearing adjusting ring until the dial indicator reads

ZERO end play. Move the differential and ring gear to the left

and right as needed. If necessary, repeat Step A or Step B.

5. Tighten each bearing adjusting ring one notch from ZERO. The

side bearings of the differential should have a preload of

15-35 lb-in (1.7-3.5 N폷m). Figure 5.62.

@

This procedure should expand the caps 0.002-0.009-inch

(0.05-0.23 mm), and place the correct preload on the bearings

when they are installed into the banjo housing.

Figure 5.62

6. Proceed to check ring gear runout.

Figure 5.59

Figure 5.60

4011993a

ADJUSTING

RING

ADJUSTING

RING TOOL

Bars must not

touch bearings.

4012325a

Figure 5.61

Figure 5.62

4012312a

Pry bars must

not touch

bearings.

4012327a

Tighten each

ring one notch.

ADJUSTING

RING TOOL

Loading...

Loading...