5 Assembly and Installation

35

Meritor Maintenance Manual MM-15103 (Issued 07-17)

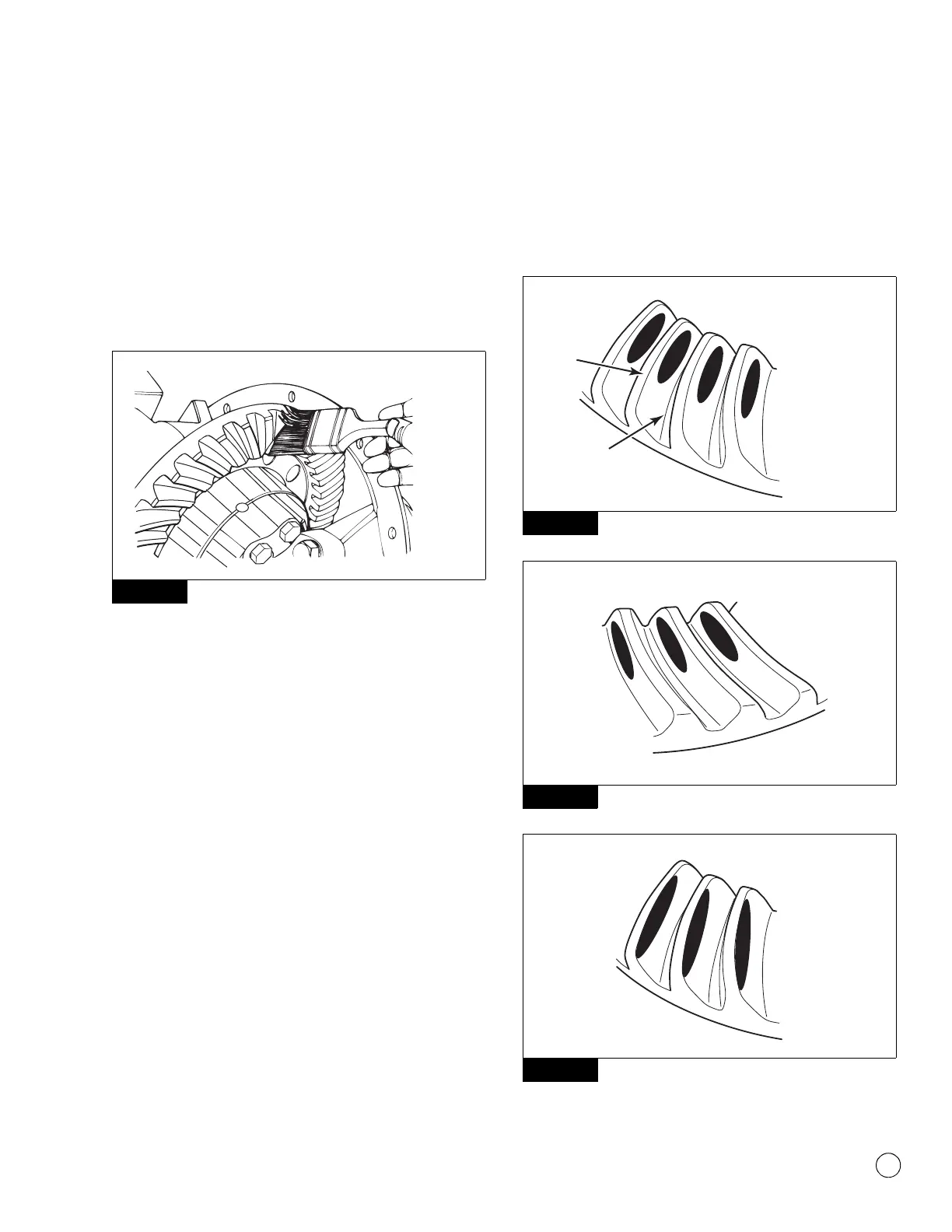

The drive side of a hypoid is the convex side of the ring gear teeth.

The drive side always takes precedence over the coast side; but the

coast side should be evaluated as well. Figure 5.37.

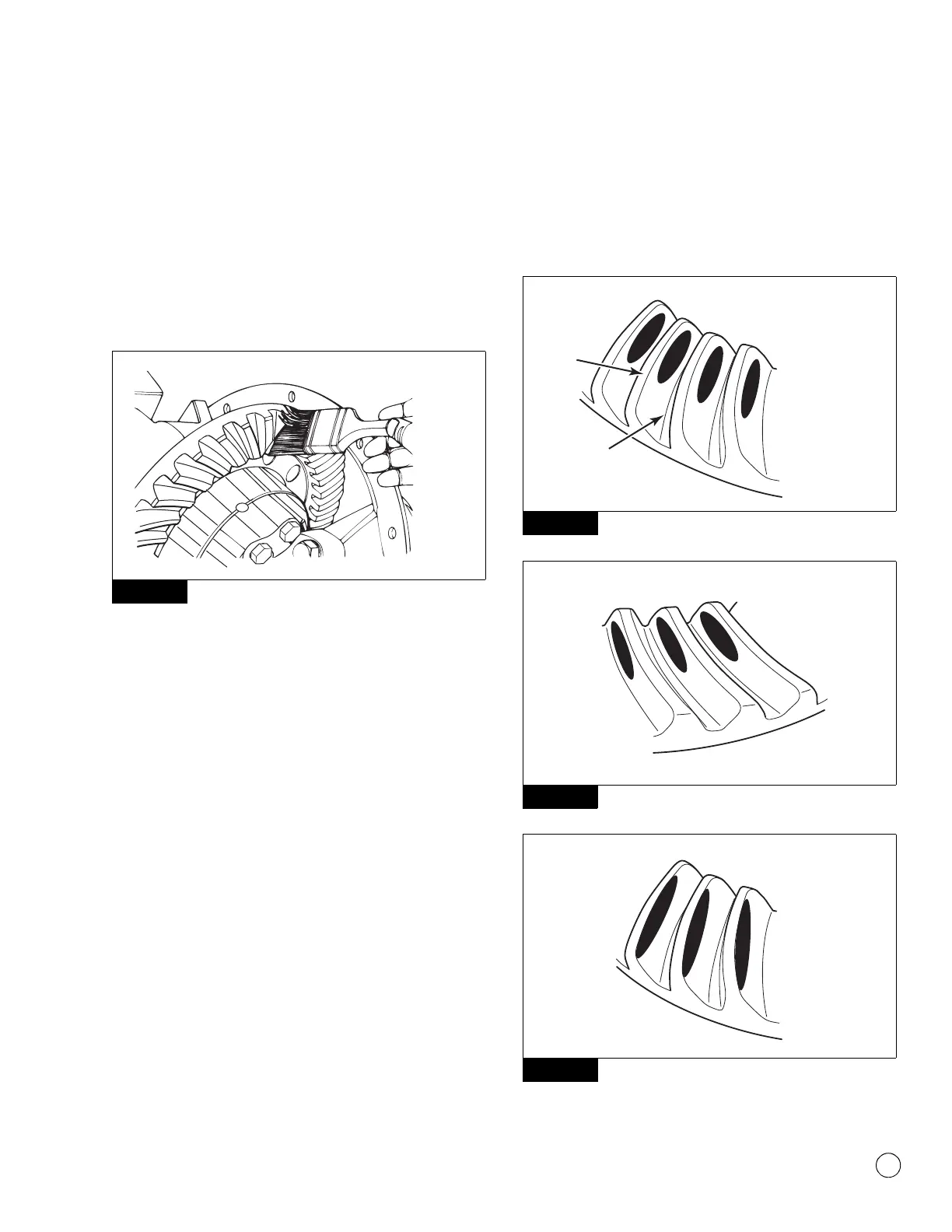

Check Gear Set Tooth Contact Patterns

1. Apply a marking compound, Multan

Gear Mark™ 39SY201

or equivalent, onto approximately 12 gear teeth of the ring

gear. Rotate the ring gear so that the 12 gear teeth are next to

the drive pinion. Figure 5.36.

Figure 5.36

2. Rotate the ring gear FORWARD and BACKWARD so that the 12

gear teeth go past the drive pinion six times to get the contact

patterns. Repeat if needed to get a more clear pattern.

3. Look at the contact patterns on the ring gear teeth. Compare

the patterns to Figure 5.37, Figure 5.38, Figure 5.39,

Figure 5.40, Figure 5.41, Figure 5.42, Figure 5.43 and

Figure 5.44.

The toe-to-heel position of the contact pattern on a good

hand-rolled gear set is toe to toe-center on both sides.

Figure 5.37 and Figure 5.38.

NOTE: When the carrier is in operation under load, a good

contact pattern will extend approximately the full length of the

gear tooth. The top of the pattern will be near the top of the

gear tooth. Figure 5.45 and Figure 5.46.

The location of a good hand-rolled contact pattern for a used

gear set will generally follow the new criteria, although the

pattern may be narrower or the center may not be filled in.

A high-contact pattern indicates that the drive pinion was not

installed deep enough into the carrier. A low-contact pattern

indicates that the drive pinion was installed too deep in the

carrier.

앫 If the contact patterns require adjustment: Continue by

following Step 4 to move the contact patterns between the

top and root of the gear teeth.

앫 If the contact patterns are centered top to root of the

gear teeth: Proceed to Step 5.

Figure 5.37

Figure 5.38

Figure 5.39

Figure 5.36

Figure 5.37

Figure 5.38

Figure 5.39

4012515a

GOOD HAND-ROLLED

PATTERN

CONCAVE

ROOT

TOP

4008132a

GOOD HAND-ROLLED

PATTERN

CONVEX

4008133a

HIGH PATTERN (BAD)

CONCAVE

Loading...

Loading...