■■■■■■■■■■■■■■■■■■■■■■

4 Operation and maintenance

858 Professional Sample Processor

■■■■■■■■

43

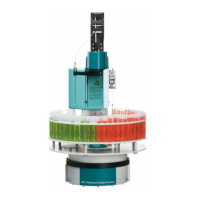

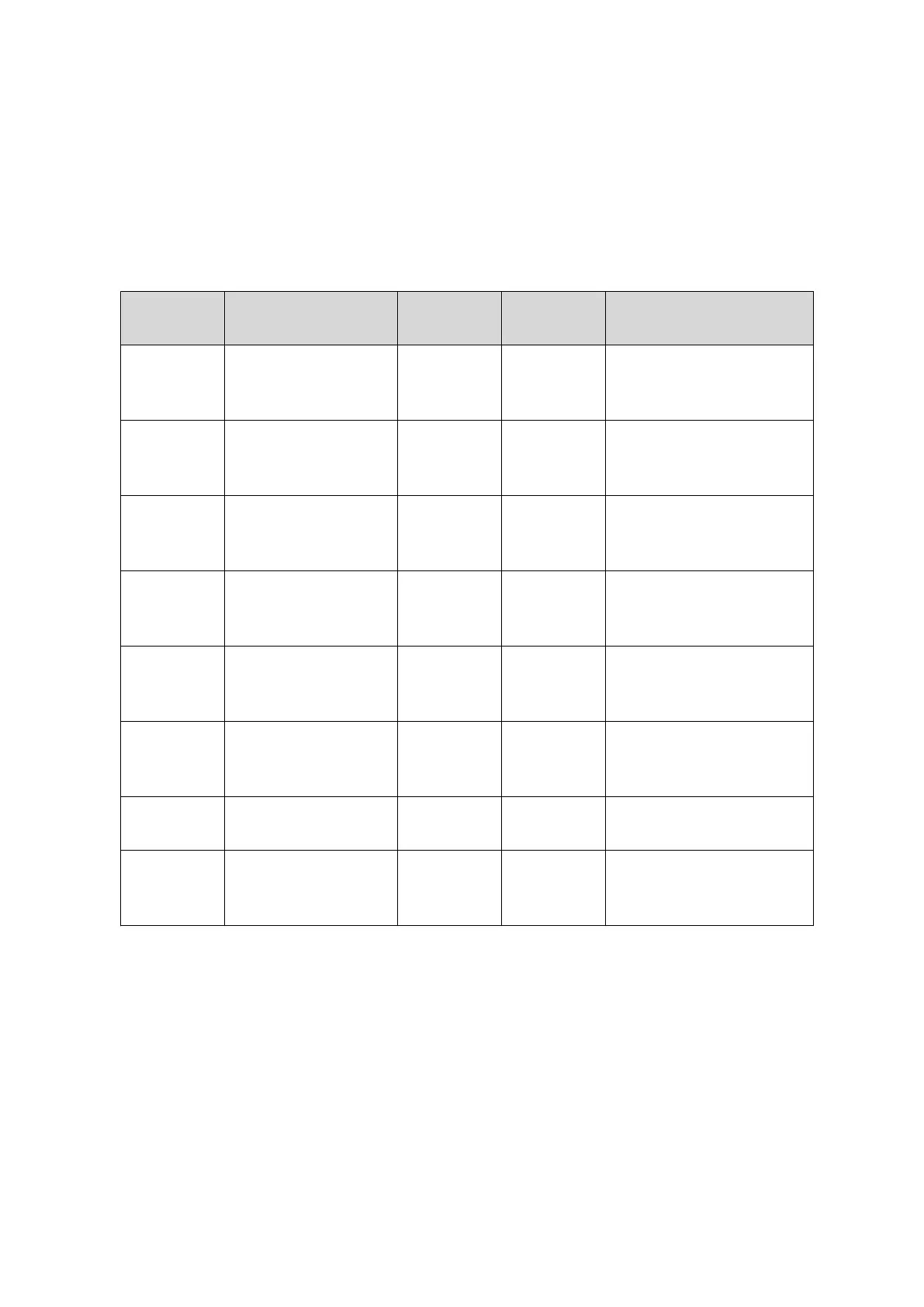

Pump tubing selection

Pump tubing can differ in terms of material, diameter and thus flow rate.

Different pump tubing is used depending on the application.

The following table shows the properties and areas of application of the

pump tubings:

Table 2 Pump tubings

Order

number

Name Material Inner

diameter

Use

6.1826.020 Pump tubing (blue/

blue), 2 stoppers

PVC

(Tygon

®

ST)

1.65 mm Pump tubing for online IC

instruments and automa-

tion in voltammetry.

6.1826.310 Pump tubing LFL

(orange/green), 3

stoppers

PVC

(Tygon

®

)

0.38 mm Pump tubing for bromate

determination using the

triiodide method.

6.1826.320 Pump tubing LFL

(orange/yellow), 3

stoppers

PVC

(Tygon

®

)

0.48 mm For acceptor solutions for

Inline Dialysis and for Inline

Ultrafiltration.

6.1826.330 Pump tubing LFL

(orange/white), 3

stoppers

PVC

(Tygon

®

)

0.64 mm No special applications.

6.1826.340 Pump tubing LFL

(black/black), 3 stop-

pers

PVC

(Tygon

®

)

0.76 mm For sample solution in

Inline Dialysis.

6.1826.360 Pump tubing LFL

(white/white), 3 stop-

pers

PVC

(Tygon

®

)

1.02 mm For sample transfer.

6.1826.380 Pump tubing LFL

(gray/gray), 3 stoppers

PVC

(Tygon

®

)

1.25 mm For Inline Dilution.

6.1826.390 Pump tubing LFL (yel-

low/yellow), 3 stop-

pers

PVC

(Tygon

®

)

1.37 mm For sample solution in

Inline Ultrafiltration.

Loading...

Loading...