■■■■■■■■■■■■■■■■■■■■■■

4 Operation and maintenance

858 Professional Sample Processor

■■■■■■■■

41

4 Operation and maintenance

4.1 General

Just like highly sensitive measuring instruments, Sample Processors require

proper care as well. Excess contamination of the instrument may result in

functional disruptions and a reduction in the lifetime of the otherwise

sturdy mechanics and electronics of the instrument.

Severe contamination can also have an influence on the measured results.

Regular cleaning of exposed parts can prevent this to a large extent.

Spilled chemicals and solvents must be removed immediately. In particular,

the connector strip (especially the power plug) should be protected from

contamination.

4.2 Injection valve

If the injection valve is blocked, then the channels of the valve can be

rinsed with water in the opposite direction. If this is not successful, then

the injection valve must be cleaned by a Metrohm service technician.

4.3 Filter

The 6.2821.130 filters (38-2) should be replaced every three months and

more frequently with higher backpressure.

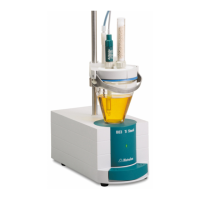

Figure 38

Pump tubing connection – Replacing the filter

1

Tubing olive

2

Filter (6.2821.130)

Pack contains 10 pieces.

3

Filter screw

Replacing the filter

1

Unscrewing the filter screw

■ Unscrew the filter screw from the tubing olive.

Loading...

Loading...