maxPAC Hardware Reference Guide

Metso Automation MAX Controls Inc. • 277596 •

11-12

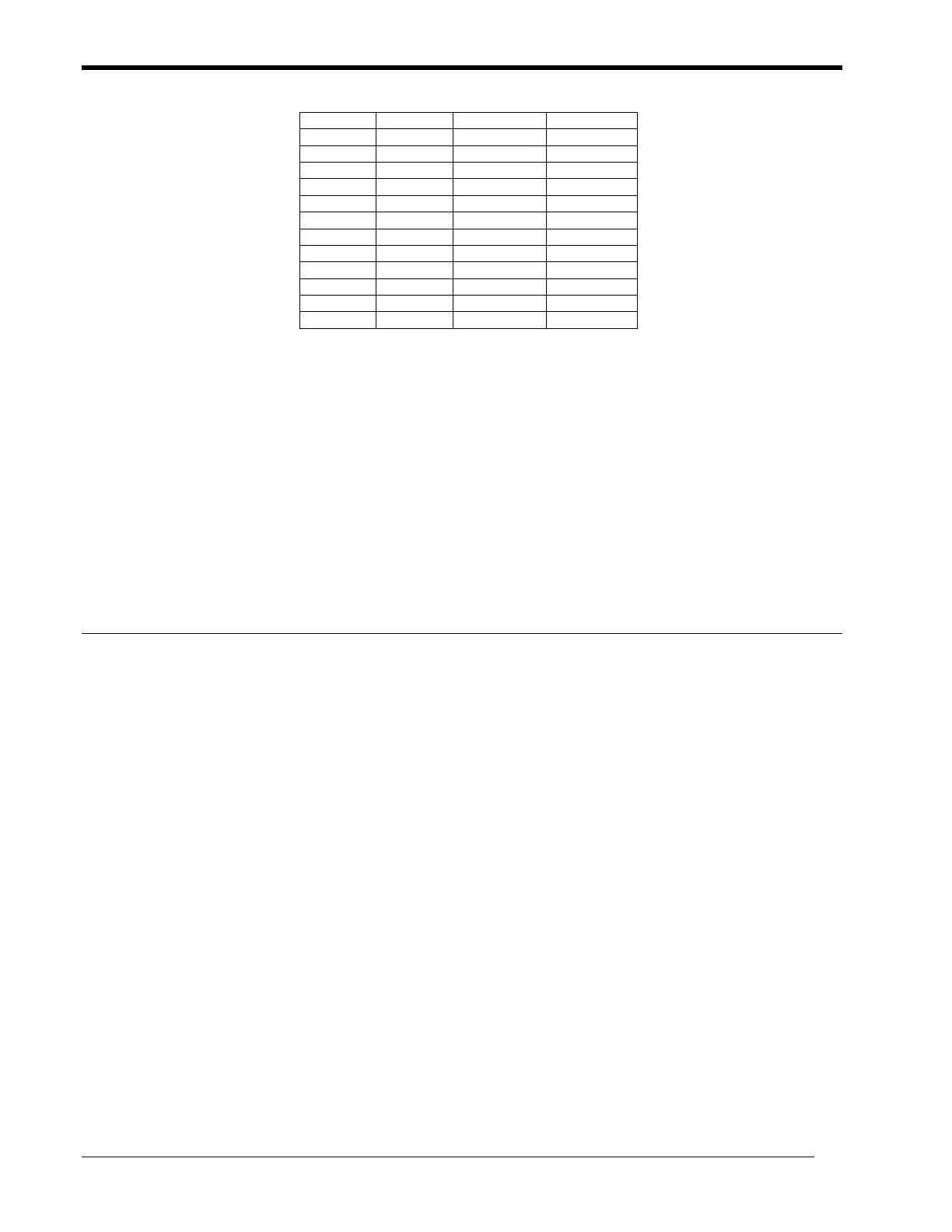

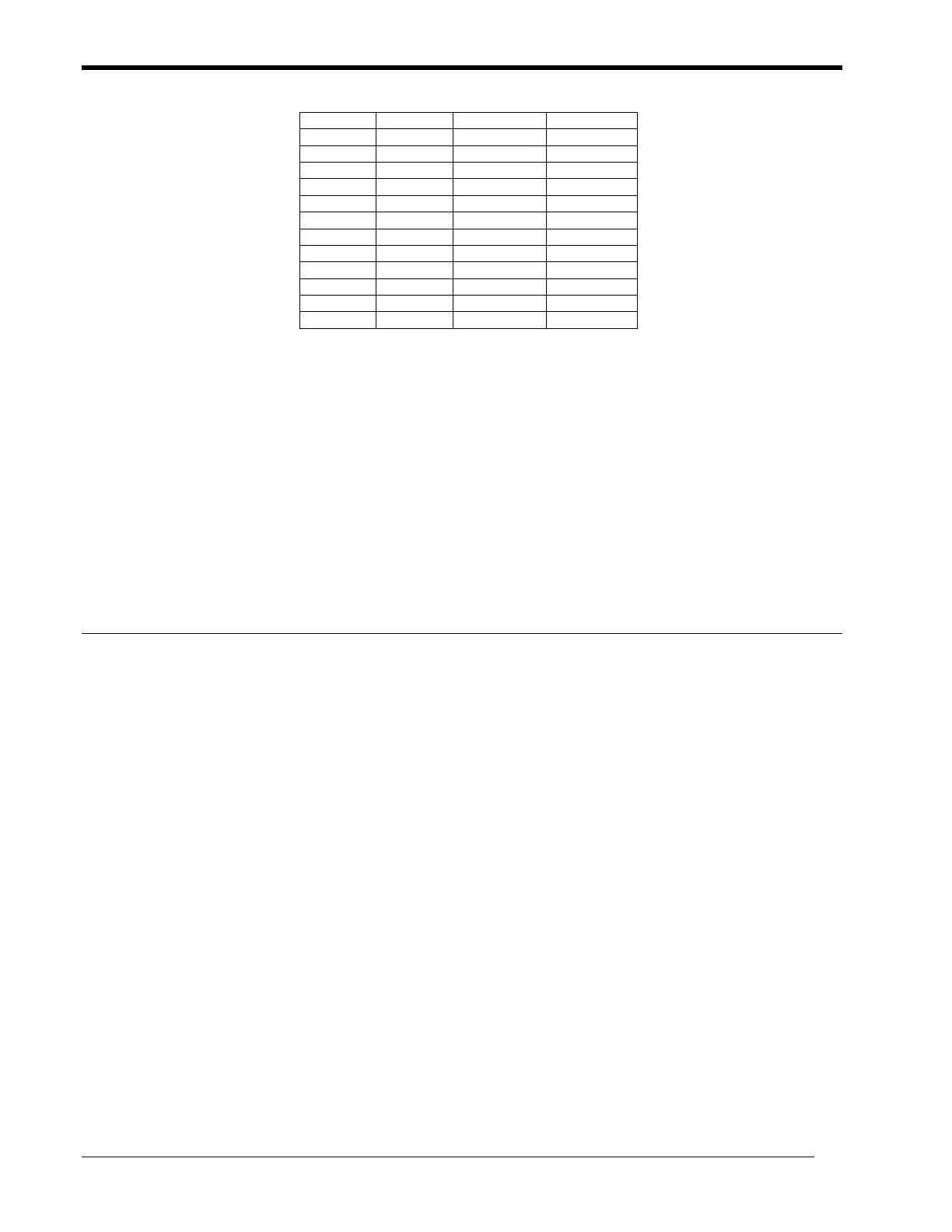

229 750 16 22

305 1000 14 20

457 1500 12 17

610 2000 10 15

762 2500 9 14

914 3000 8 13

1067 3500 7 12

1219 4000 6 11

1372 4500 6 10

1524 5000 5 9

1676 5500 4 9

1829 6000 4 8

2000 6500 4 8

Links can be in series or in parallel, the preferred configuration approach. In

a parallel link, a star approach, each remote location's BEM is connected to a

BEM located on the electrical bus with the DPU.

In a series link, the links can be configured such that one BEM and DPU

connects to a remote's BEM and its rack. This rack then contains another

BEM, which is then connected to a second remote's rack with its BEM. This

configuration approach introduces time delays, which will limit the number

of supported modules. Consult the factory if more than two links are on one

DPU.

Ensuring Link Availability

To ensure link availability, installations may include multiple levels of

redundancy. In configurations using only a single DPU, redundant cables

ensure availability. The loss of either cable pair will automatically route the

signal to the alternate cable pair. Only a momentary loss of the remote I/O,

(milliseconds), will occur while the Extender switches over to the inactive

cable.

To ensure optimal availability, each cable pair should be routed separately to

minimize the probability of damage to both cables. With separate cables, in

the event a cable should break or fail, a second cable is still available.

In configurations using redundant DPUs, each DPU can have its own bus

Extender to the remote location. Any single failure of the Extender or cable

will not result in loss of operation, and the replacement of the failed

component can occur without loss of service.

A failure in the remote location will only affect the remote I/O modules

associated with the remote Extender.

Refer to the front-panel LEDs and a digital output to identify fault conditions

detected by the link, specifically loss of lock and receive error.

Loading...

Loading...