Do you have a question about the Miller Dimension 650 and is the answer not in the manual?

Explains symbols used for warnings and instructions in the manual.

Details potential hazards associated with arc welding processes.

Covers hazards like fumes, gases, arc rays, fire, flying metal, and EMF.

Provides additional symbols for installation, operation, and maintenance.

Lists chemicals known to cause birth defects or cancer.

References key industry safety standards for welding and cutting.

Explains electromagnetic fields and their potential impact on medical devices.

Defines specific safety symbols found on CE products.

Lists and defines various symbols used throughout the manual.

Highlights key features and operational benefits of the welding unit.

Describes controls that influence arc characteristics like DIG and Inductance.

Location and importance of the unit's serial and rating information.

Provides detailed technical data on input, output, and ratings.

Physical dimensions and weight of the welding power source.

Details IP rating and guidelines for operating environment.

Explains duty cycle limitations and overheating protection.

Describes the output characteristics for different welding processes.

Guidance on choosing a suitable location for the welding unit.

Recommendations for choosing appropriate weld cable sizes.

Identification of positive and negative weld output terminals.

Instructions for properly connecting weld output cables.

Details on the Remote 14 receptacle and its socket functions.

Information on the supplementary protectors for unit circuits.

Guidance on electrical service requirements for the unit.

Step-by-step instructions for connecting the unit's input power.

Description of the front panel controls and displays.

Details on different mode switch positions and their functions.

Information on optional low OCV operation modes.

Explains how to view and change alternate machine configurations.

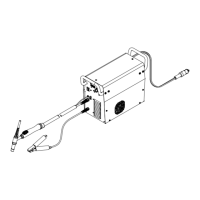

Illustrates the typical connection setup for GTAW welding.

Details on operating the unit in TIG Remote welding mode.

Instructions for using the Lift-Arc TIG welding mode.

Typical connection for a remote control feeder in GMAW/FCAW.

Details on operating the unit in MIG Remote welding mode.

Typical connection for a voltage-sensing feeder in GMAW/FCAW.

Instructions for MIG welding with gas output.

Instructions for MIG welding without gas.

Typical connection setup for SMAW and CAC-A processes.

Details on operating the unit in Stick Remote welding mode.

Instructions for operating the unit in Stick-Output-On mode.

Instructions for operating the unit in Gouge mode.

Illustrates the typical connection setup for SAW welding.

Details on operating the unit in Subarc welding mode.

Schedule and procedures for routine maintenance of the unit.

Instructions for cleaning internal components by blowing out dust.

Explanation of 'HELP' codes displayed by the unit.

Lists common problems and their recommended solutions.

Exploded view and part numbers for the main assembly.

List of parts for the front panel assembly.

List of parts for the right-side wind tunnel assembly.

List of parts for the left-side wind tunnel assembly.

List of parts for the rear panel assembly.

| Input Frequency | 50/60 Hz |

|---|---|

| Input Phase | 1/3-Phase |

| Rated Output | 650 A |

| Duty Cycle | 60% |

| Welding Processes | MIG, TIG, Stick |

| Open-Circuit Voltage (OCV) | 80V |