ENGINE – Crankshaft and Flywheel

11-72

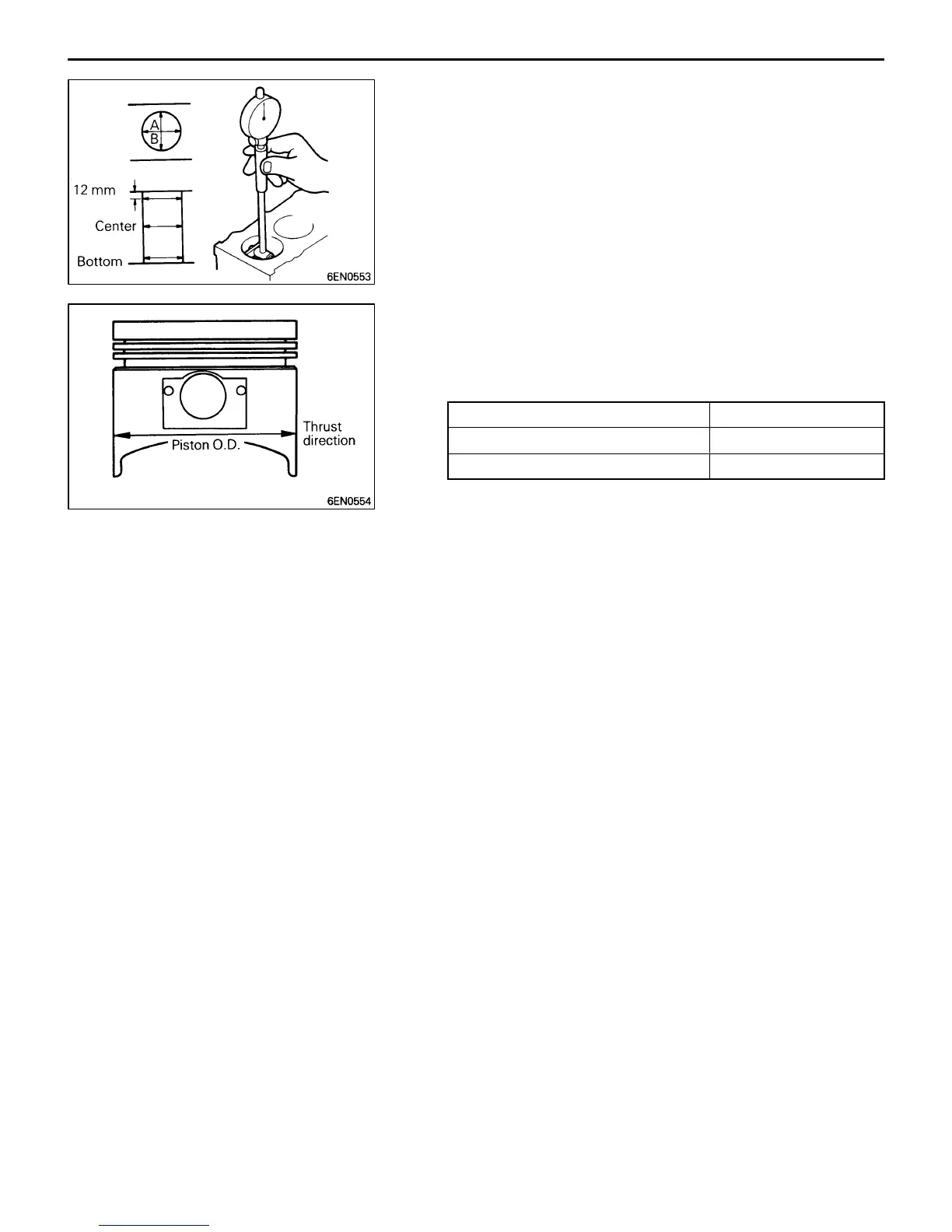

(5) Using cylinder gauge, measure the cylinder bore and

cylindricity. If worn badly, correct cylinder to an oversize

and replace piston and piston rings. Measure at the points

shown in illustration.

Standard value:

Cylinder I.D. 85.00 – 85.03 mm

Cylindricity 0.01 mm or less

BORING CYLINDER

(1) Oversize pistons to be used should be determined on

the basis of the largest bore cylinder.

Piston size identification

Size Identification mark

0.50 O.S. 50

1.00 O.S. 100

NOTE

Size mark is stamped on the piston top.

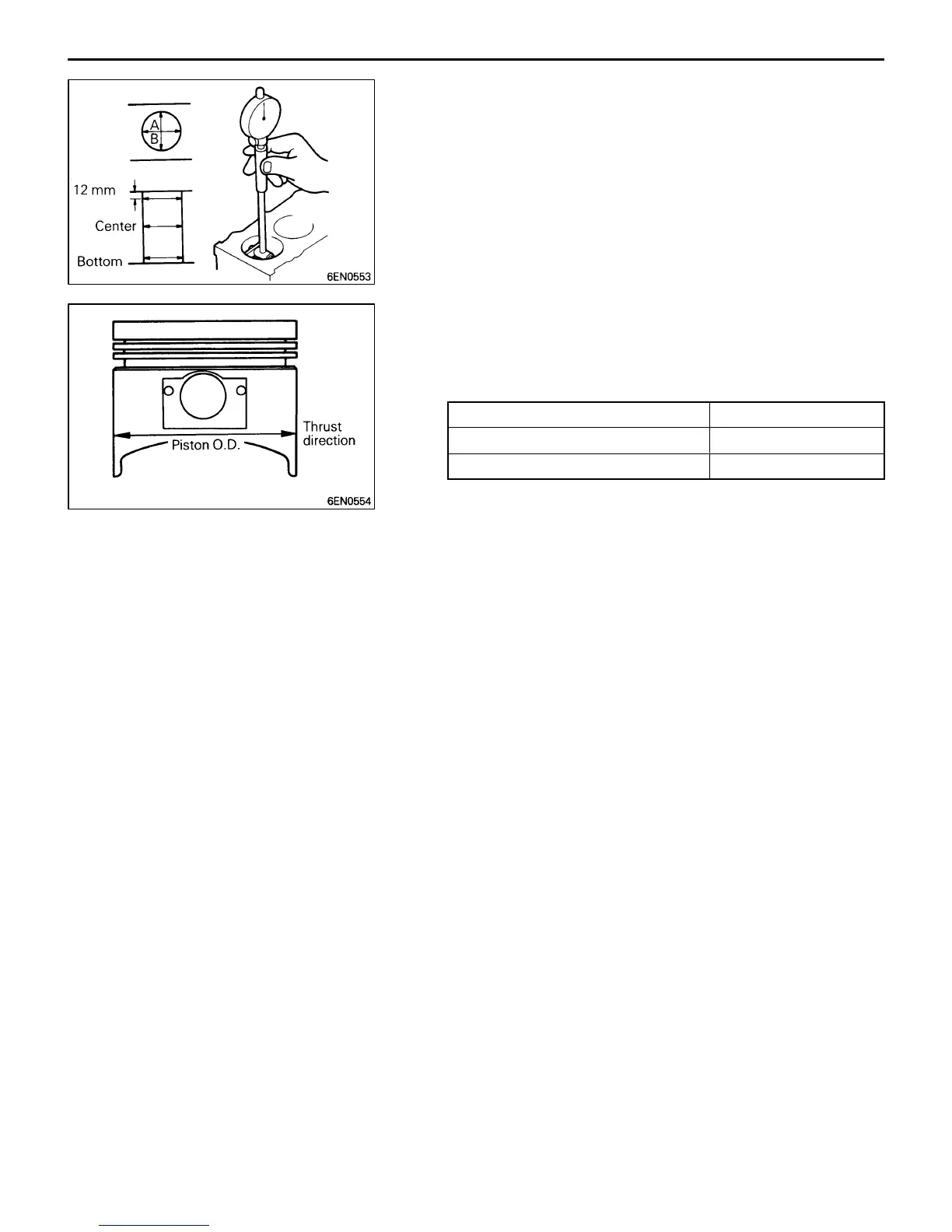

(2) Measure outside diameter of piston to be used. Measure

it in thrust direction as shown.

(3) Based on the measured piston O.D. calculate boring finish

dimension.

Boring finish dimension = Piston O.D. + (clearance

between piston O.D. and cylinder) – 0.02 mm

(honing margin)

(4) Bore all cylinders to the calculated boring finish dimension.

Caution

To prevent distortion that may result from temperature

rise during honing, bore cylinders, working from No.

2, No. 4, No. 1 to No. 3.

(5) Hone to final finish dimension (piston O.D. + clearance

between piston O.D. and cylinder).

(6) Check clearance between piston and cylinder.

Clearance between piston and cylinder:

0.02 – 0.04 mm

NOTE

When boring cylinders, finish all of four cylinders to same

oversize. Do not bore only one cylinder to an oversize.

Loading...

Loading...