2-8

Installation

2Unpacking to Installation

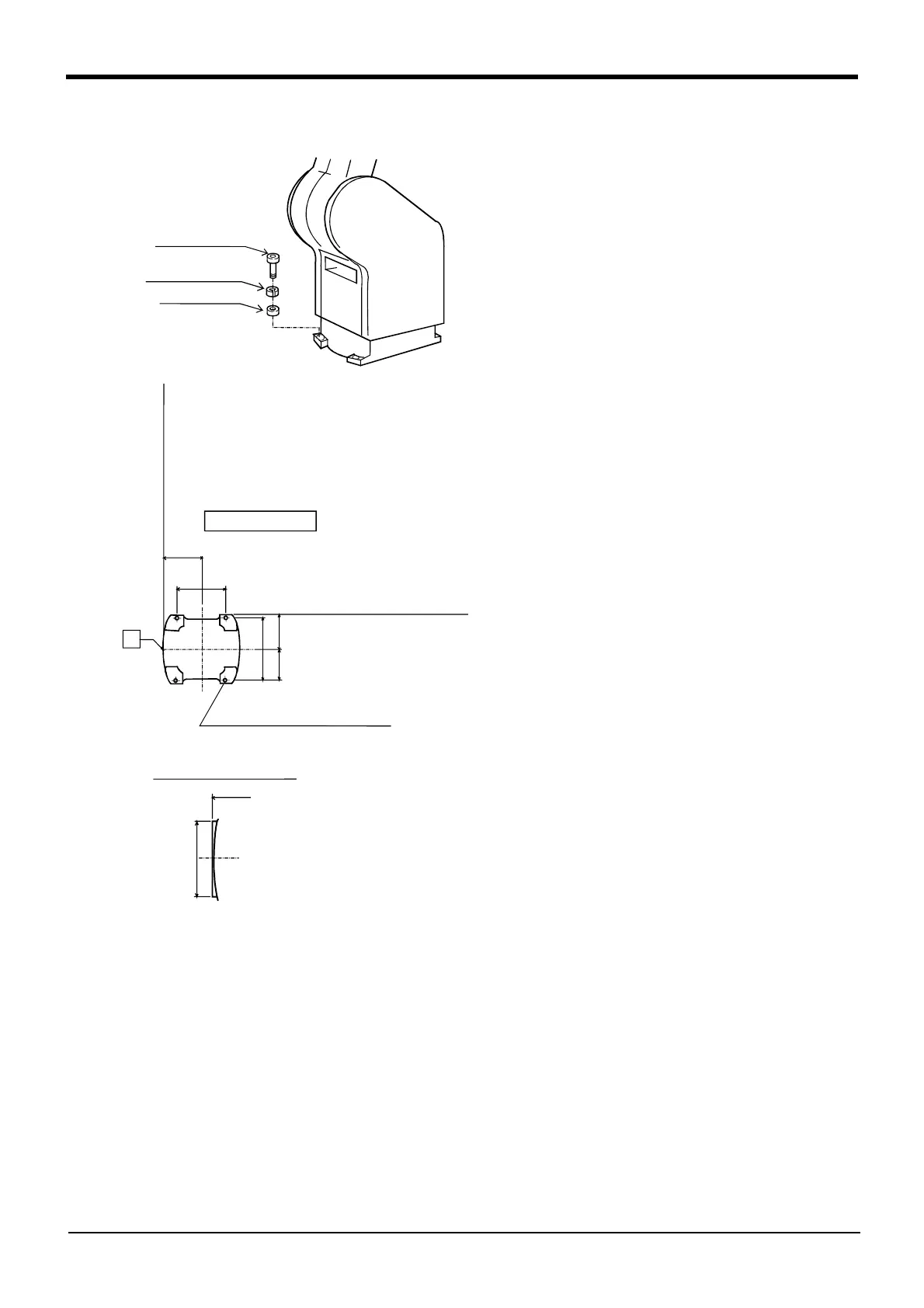

2.2.3 Installation procedures

1) The robot installation surface has been machine

finished. Use the installation holes (4-φ9 holes)

opened at the four corners of the base, and

securely fix the robot with the enclosed installa

-

tion bolts (M8 x 30 hexagon socket bolts).

2) Install the robot on a level surface.

3) It is recommended that the surface roughness of

the table onto which the robot is to be installed

by 6.3a or more. If the installation surface is

rough, the contact with the table will be poor, and

positional deviation could occur when the robot

moves.

4) When installing, use a common table to prevent

the position of the devices and jigs subject to

robot work from deviating.

5) The installation surface must have sufficient

strength to withstand the arm reaction during

operation, and resistance against deformation and

vibration caused by the static (dynamic) load of

the robot arm and peripheral devices, etc.

Fig.2-3 : Installation dimensions

Springwasher

Flatwasher

4‑M8X30

Hexagonsocket

headbolt

(4locations)

Frontofrobot

(Viewfrombottom)

4‑φ9installationholes

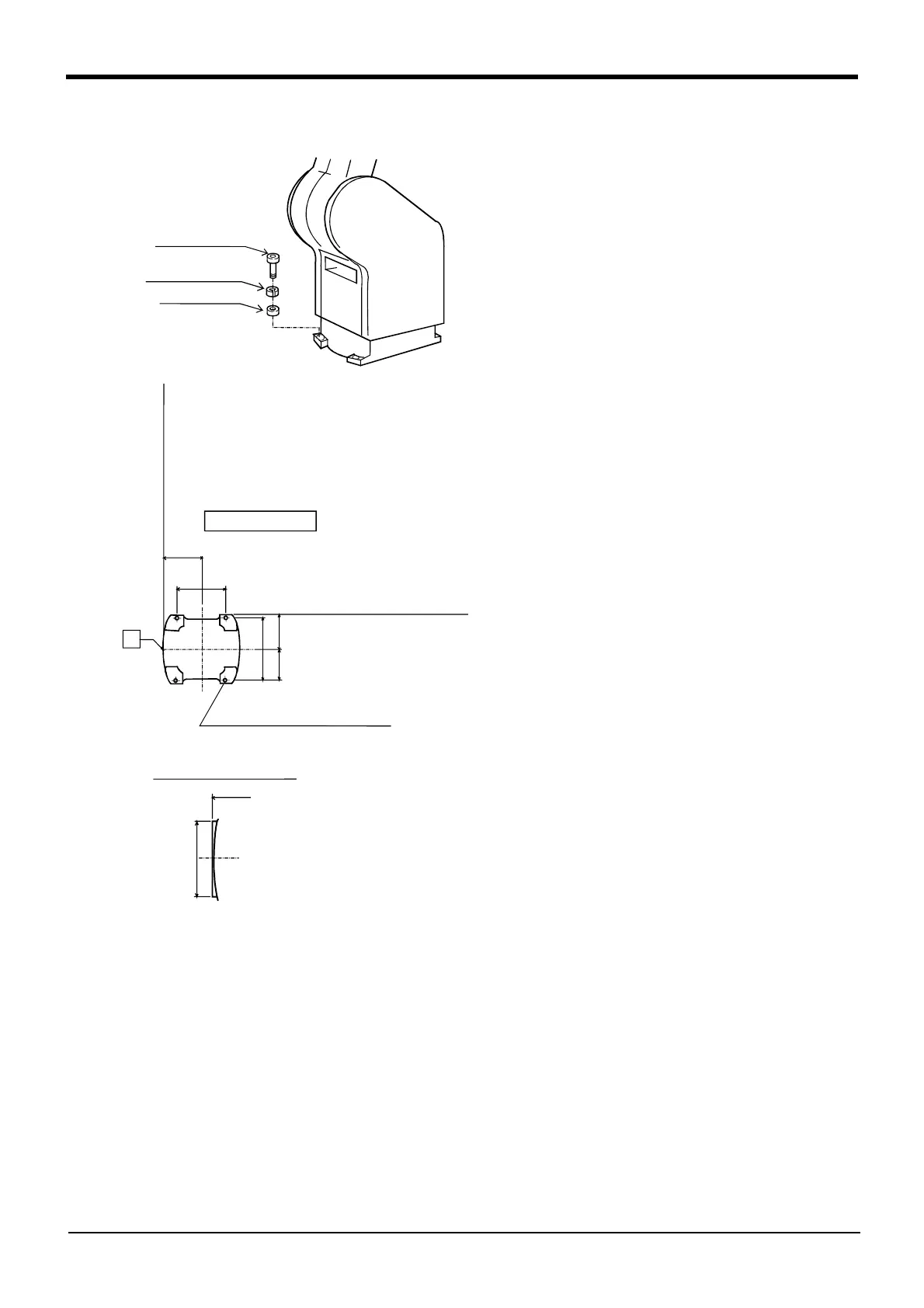

MagnifiedviewofC

122

160

115

122

C

6.3a(Installationstandardsid

205

102.5

50

6.3a(Installationstandardside

Loading...

Loading...