NICE5000 User Manual 5 System Commissioning and Functions

- 85 -

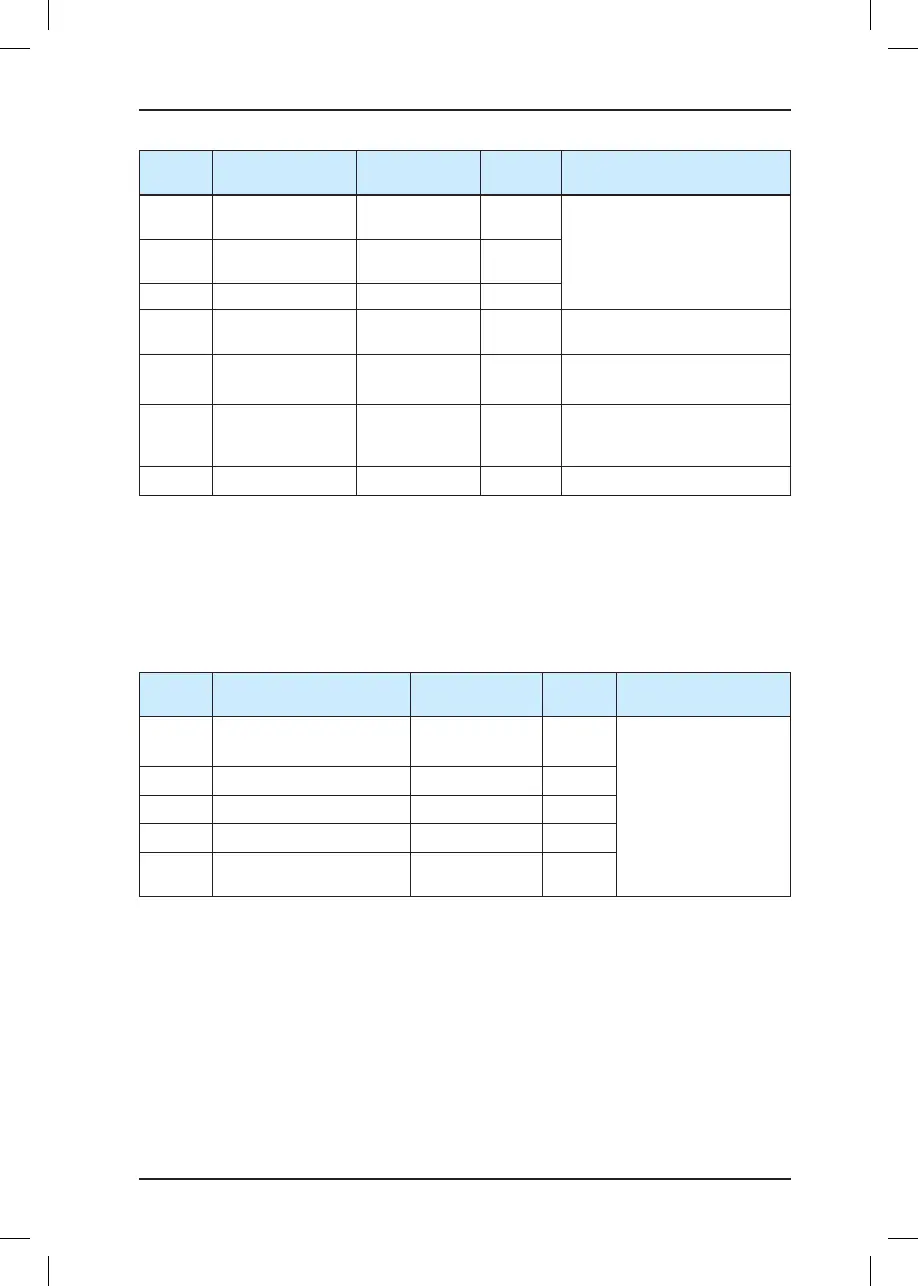

Function

Code

Parameter Name Setting Range Default Description

F2-22

Startup acceleration

time

0.000–1.500s 0.000s

It can reduce the terrace

feeling at startup caused by the

breakout friction of the guide rail.

F3-00

Startup speed 0.000–0.030 m/s 0.000 m/s

F3-01

Startup holding time 0.000–0.500s 0.000s

F3-18

Zero-speed control

time at startup

0.000–1.000s 0.200s

It species the zero speed

holding time before brake output.

F3-19

Brake release delay 0.000–2.000s

0.200s

0.600s

It species the brake release

time.

F3-20

Zero-speed control

time at end

0.000–1.000s 0.300s

It species the zero speed

holding time after the brake is

applied.

F3-21

Brake apply delay 0.200–1.500s 0.200s It species the brake apply time.

For details on these parameters, see the running time sequence in Figure 7-3.

The release time of the brakes varies according to the types and the response time of the

brakes is greatly inuenced by the ambient temperature. A very high brake coil temperature

slows the brake responsiveness. Thus, when the riding comfort at startup or stop cannot

be improved by adjusting position lock or load cell compensation parameters, appropriately

increase the values of F3-19 and F3-21 to check whether the brake release time inuences

the riding comfort.

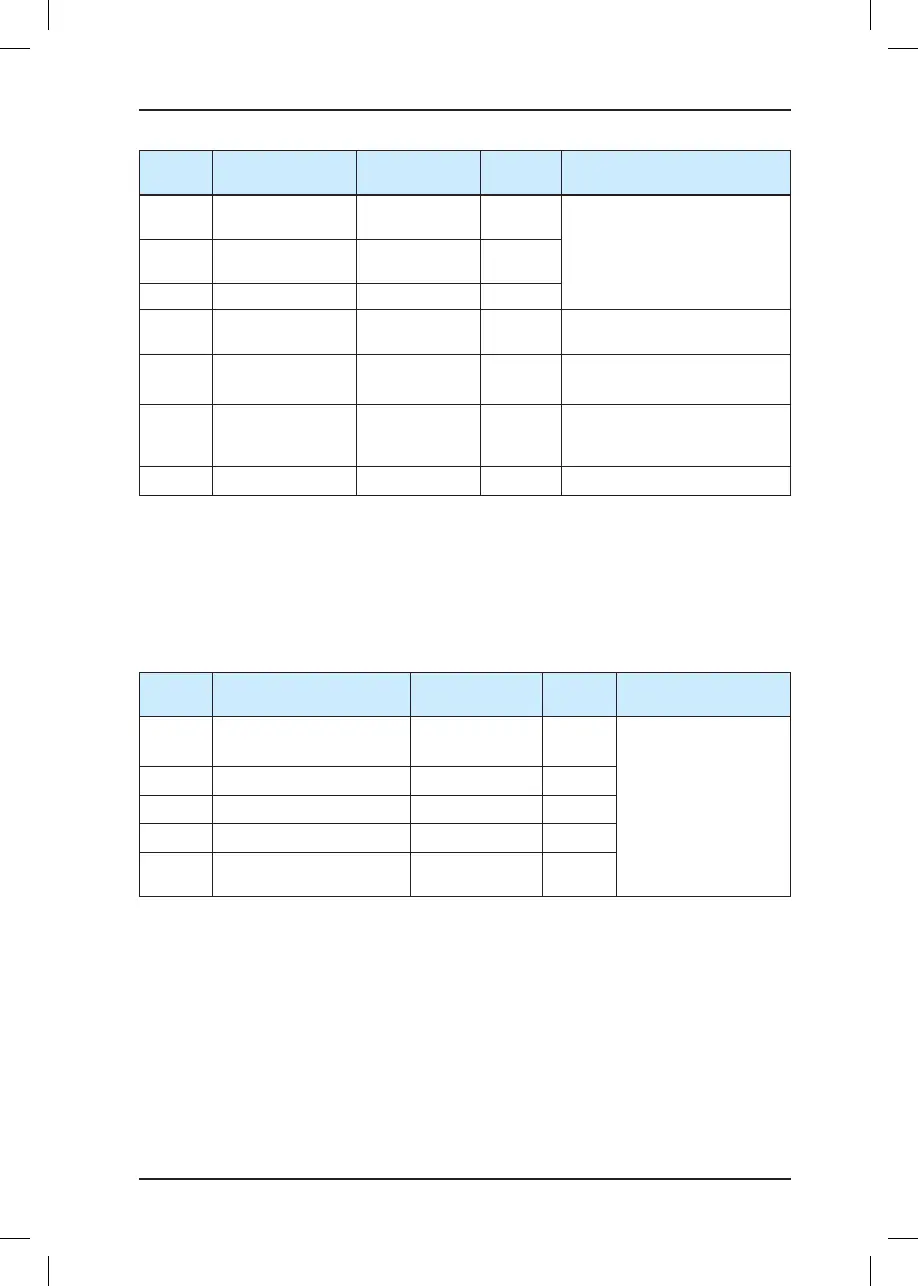

Function

Code

Parameter Name Setting Range Default Remarks

F2-11

No-load-cell startup

0: Invalid

1: Valid

0

These are position lock

regulating parameters

when automatic pre-

torque compensation is

used (F8-01 = 1).

F2-12

Position lock speed Kp 0.00–2.00 0.50

F2-13

Position lock speed Ki 0.00–2.00 0.60

F2-14

Position lock current KP1 10–1000 60

F2-15

Position lock current loop

KI1

10–1000 30

When automatic pre-torque compensation is used (applicable to all types of encoder, but

best effect for ERN1387) the system automatically adjusts the compensated torque at

startup.

a. Set F2-11 to 1 to enable no-load-cell startup.

b. Gradually increase F2-12 (Position lock current coefcient) but ensure that the motor

does not oscillate.

c. Gradually increase F2-13 if increasing F2-12 cannot meet the torque compensation

requirement.

Loading...

Loading...