Specification TWINsync module

24

6 TWINsync operation modes

ID no.: CB08759-001Date: 03/2023

moog

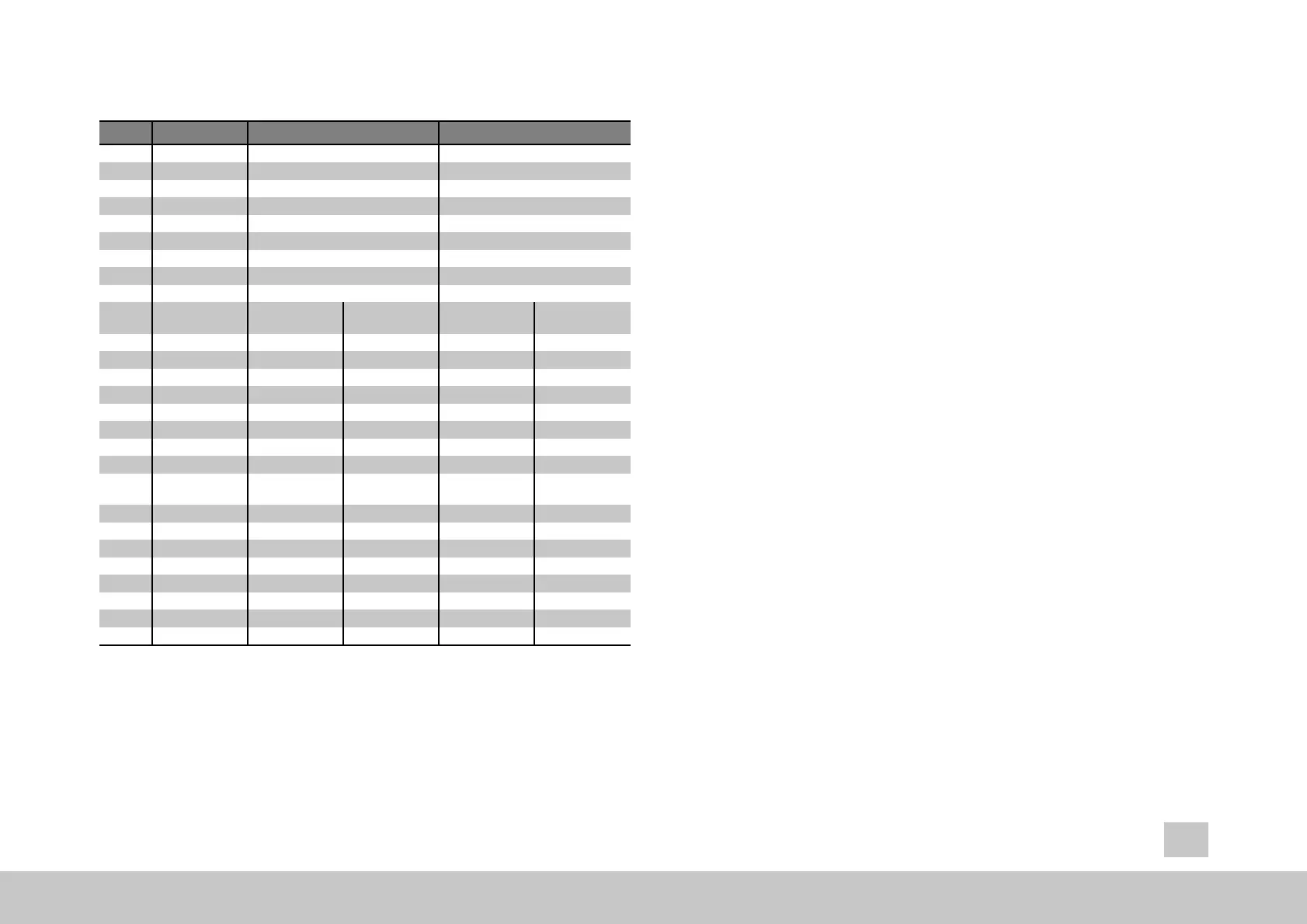

ID Parameters Setting in the master Setting in the slave

P2614 TWINdrive mode MASTER (2) SLAVE (1)

P2580 TWIN_Setting USER(0) USER(0)

P0300 Control mode - - - - - -

P0159 Control selector - - - - - -

P0165 Setpoint selector - - - - - -

P0301 Setpoint mode - - - - - -

P2584 Speed-up - - - - - -

P2602 Local scaling - - - - - -

P2609 Remote scaling - - - - - -

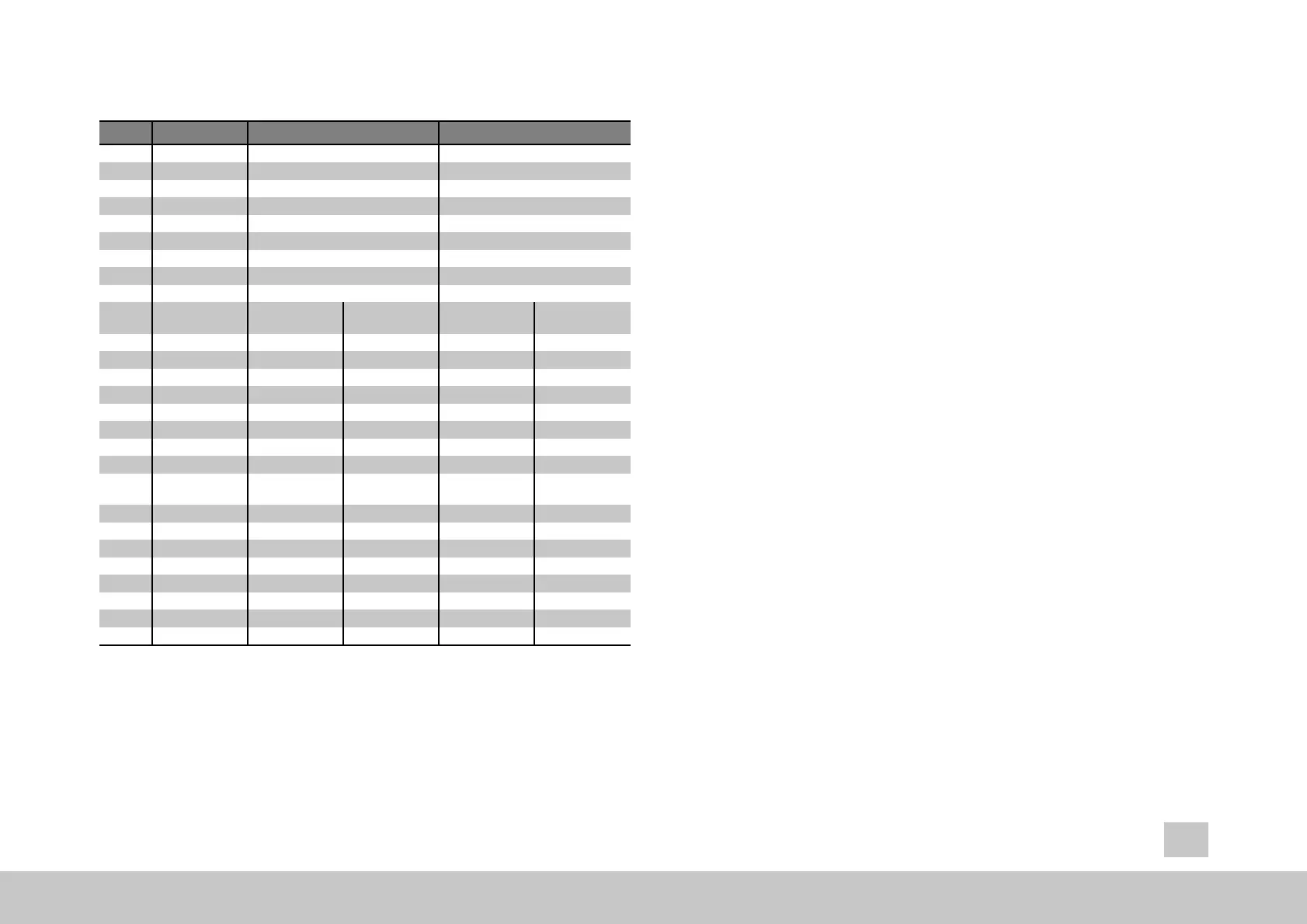

P2615 Mapping of the

sent data

Parameter value

(hex)

Meaning Parameter value

(hex)

Meaning

Sub-ID 0 0000.000x x objects (x = 0..7) 0000.000x x objects (x = 0..7)

Sub-ID 1 pppp.SSww 1. Object pppp.SSww 1. Object

Sub-ID 2 pppp.SSww 2. Object pppp.SSww 2. Object

Sub-ID 3 pppp.SSww 3. Object pppp.SSww 3. Object

Sub-ID 4 pppp.SSww 4. Object pppp.SSww 4. Object

Sub-ID 5 pppp.SSww 5. Object pppp.SSww 5. Object

Sub-ID 6 pppp.SSww 6. Object pppp.SSww 6. Object

Sub-ID 7 pppp.SSww 7. Object pppp.SSww 7. Object

P2616 Mapping of the

received data

Parameter value

(hex)

Meaning Parameter value

(hex)

Meaning

Sub-ID 0 0000.000x x objects (x = 0..7) 0000.000x x objects (x = 0..7)

Sub-ID 1 pppp.SSww 1. Object pppp.SSww 1. Object

Sub-ID 2 pppp.SSww 2. Object pppp.SSww 2. Object

Sub-ID 3 pppp.SSww 3. Object pppp.SSww 3. Object

Sub-ID 4 pppp.SSww 4. Object pppp.SSww 4. Object

Sub-ID 5 pppp.SSww 5. Object pppp.SSww 5. Object

Sub-ID 6 pppp.SSww 6. Object pppp.SSww 6. Object

Sub-ID 7 pppp.SSww 7. Object pppp.SSww 7. Object

Table 6.4: Parameters for the master and slave drives of the pre-set TWINsync

operation mode: User-specific mapping

pppp: Parameter ID in hex

SS: Parameter Sub-ID in hex

ww: 10 hex for 16 bit, 20 hex for 32 bit

6.2.2 TWin Drive profile “TWD”

(speed)

... with virtual encoder!

The "TWin Drive profile TWD" (speed) operation mode is suitable for speed

synchronization of mechanically coupled axes, for example, of travel or lift drives

with a double drive. The master sends its actual speed value and its actual torque

value to the TWINsync slave via the TWINsync interface. The TWINsync slave then

processes these two variables and passes them on to its internal control structure.

6.2.2.1 TWD_MASTER_V1 / TWD_SLAVE_V1, 1+2

This operation mode is selected by choosing P2580 = TWD_MASTER_V1 for the

master and P2580 = TWD_SLAVE_V1 for the slave. In this operating mode, the

master sends its torque actual

value (P2597) and its speed actual value (P2599) to

the slave. The received

data, which the master expects via TWINsync, are interpreted

as current error number (P2650[0]) and current error location (P2650[1]) of the slave

drive.

In this operating mode, the speed actual value of the master drive is used as th

e

main speed setpoint (main setpoint) of the slave drive. An additional setpoint value

is added to the main setpoint value which is proportional to the main setpoint value and

which is specified as a percentage of parameter P2584. If the additional setpoint value

calculated in this way goes below the threshold value specified in parameter P2585

(speed-up minimum), then this threshold value is used as the additional setpoint value.

The sign of the additional setpoint value corresponds to the sign of the torque actual

value of the master drive.

Loading...

Loading...