Specification TWINsync module

16

4 Description of parameters

ID no.: CB08759-001Date: 03/2023

moog

4.1.5 Configuration of the process data in the extended-

mapping mode

The so-called extended-mapping mode can be selected via the operation mode

selector “TWIN_Setting”.

Depending on whether the axis is a TWINmaster or a TWINslave, this operation

mode is selected by choosing P2580 = EXT_MAP_MASTER for the master and

P2580

= EXT_MAP_SLAVE for the slave.

For more on this, see the corresponding chapter on selecting the operation modes

(chapter "TWINsync operation modes" on page 19).

4.1.6 Scaling of the process data

In order to be able to transmit the three

most commonly used variables, torque,

speed and position, via the TWINsync interface simultaneously, a corresponding

scaling of the torque and speed variables from the 4-byte floating-point format used

internally to a scaled 2-byte integer format has been implemented. The references

used for scaling the “local” torque and speed values (sent data) are specified using

the parameter (P2602) MPRO_TWIN_LocalScaling. The references used for

descaling the torque and speed values received from the external drive (“remote”)

are specified using the parameter (P2609) MPRO_TWIN_RemoteScaling (see the

next table).

The first field entry (SubID: 0) in P2602 / P2609 contains the value of the reference

to

rque in Nm. The second field entry (SubID: 1) contains the value of the reference

speed in rpm. The third field entry (Sub-ID: 2) contains the value of the reference

current in 100 mA (see P2697[2]). The scaling represents the value range between

the negative and positive reference value over the numerical range [-32768 ...

32767]. The position data are transferred in the format specified by the units

parametrization of the device (factor group) as a 32-bit integer.

NOTE:

Generally speaking, the references P2602 / P2609 and the factor-group

settings in the master and slave drives shou

ld be identical.

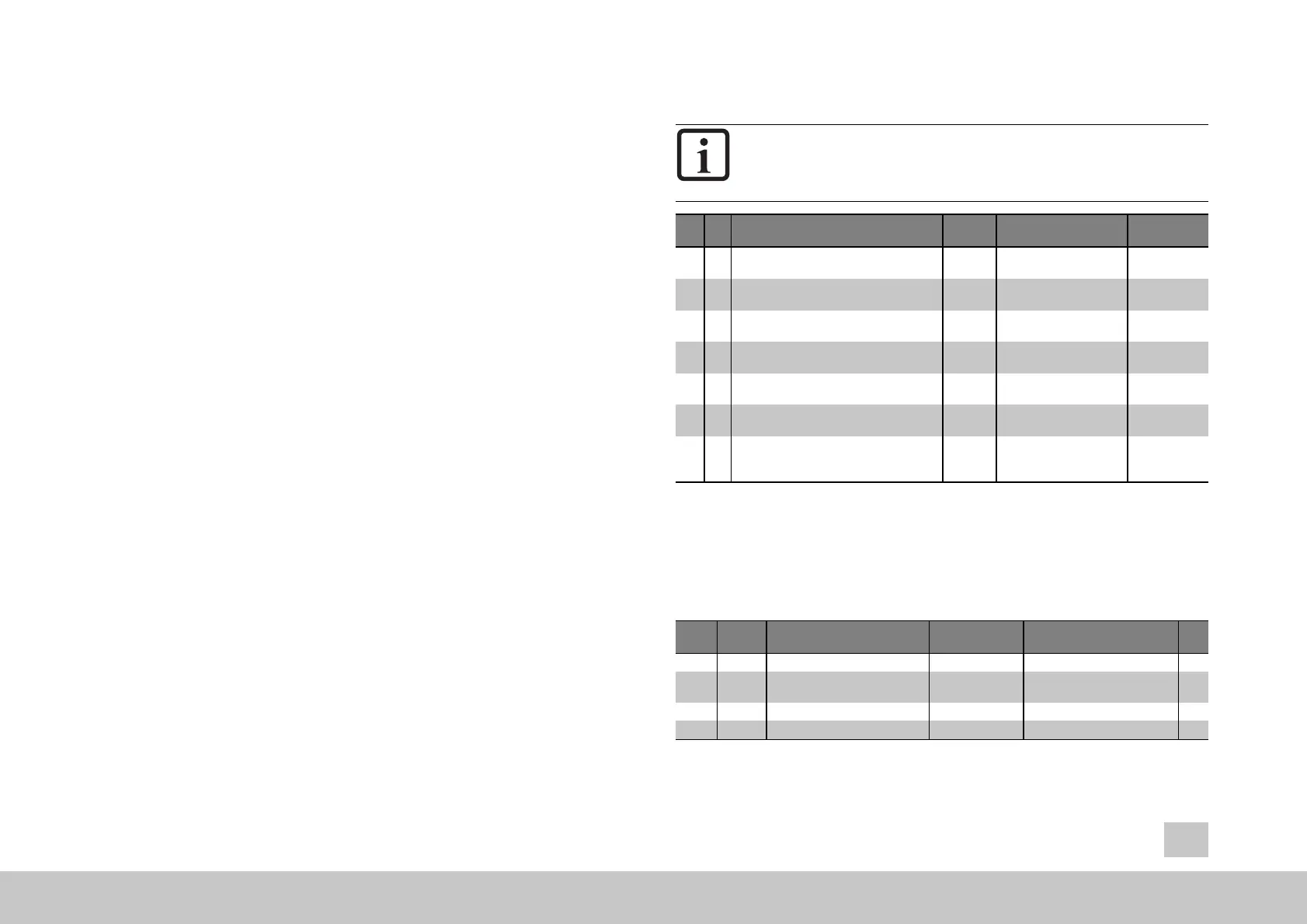

ID

I

S

D

ub

Name Unit Description Data type

P

2602

0 Nm Reference torque, local

drive

Float32

1 rpm Reference speed, local

drive

Float32

P

2609

0 Nm Reference torque,

external drive

Float32

1 rpm Reference speed, external

drive

Float32

2

MPRO_TWIN_LocalScaling

MPRO_TWIN_LocalScalingTorque

MPRO_TWIN_LocalScalingSpeed

MPRO_TWIN_RemoteScaling

MPRO_TWIN_RemoteScalingTorque

MPRO_TWIN_RemoteScalingSpeed

MPRO_TWIN_RemoteScaleCurrent 100 mA Reference current,

external drive (see P2697

[2])

Float32

Table 4.7: References for scaling the local

and the

external torque and speed

signals

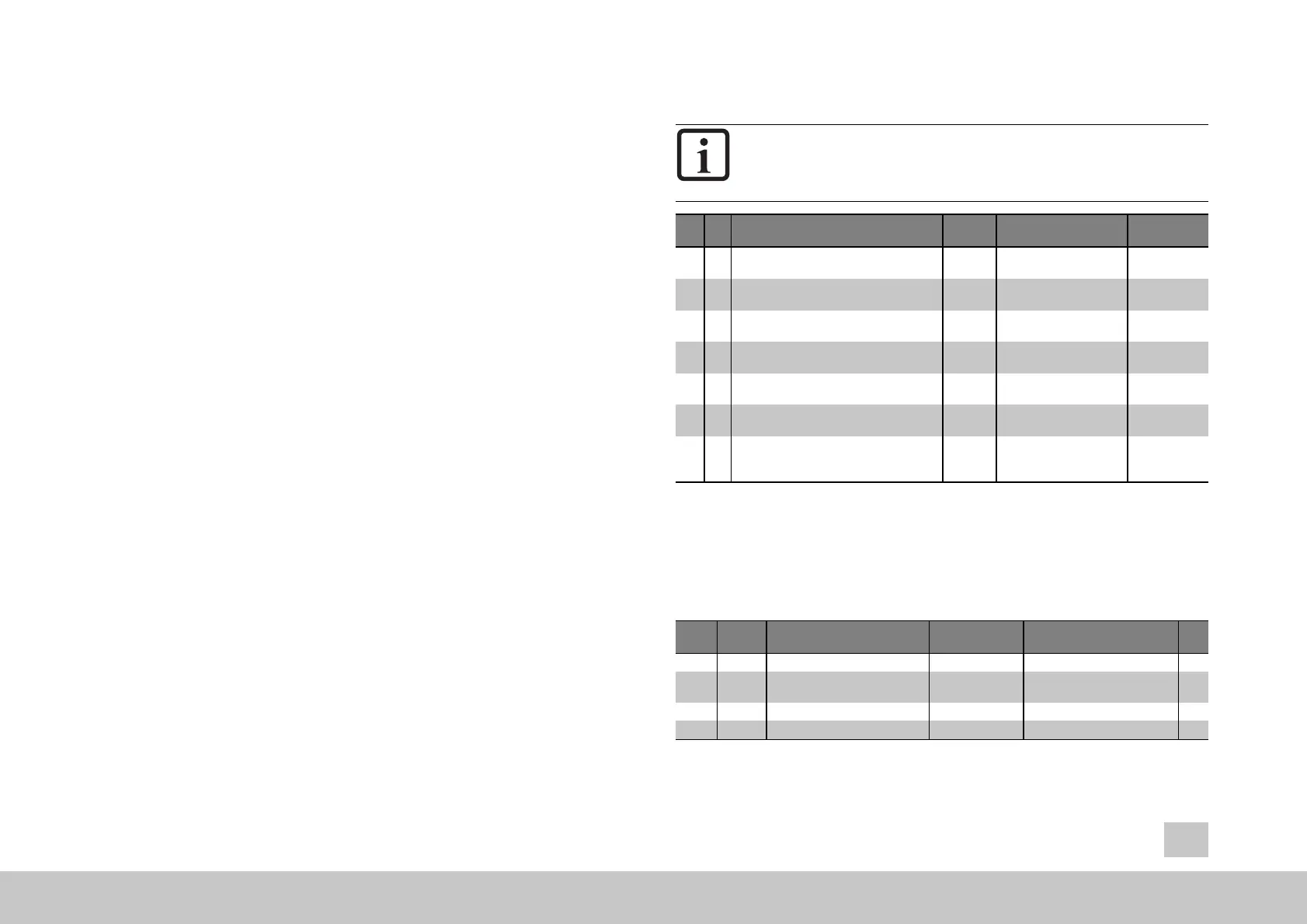

The following table shows the parameters typically used for the process data which

are to be sent. The parameters

P2596 - P2601 describe the “local” setpoint and

actual values for torque, speed and position.

ID Sub ID Name Unit Description

Data

type

P 2596 0 scaled Int16

P 2597 0

MPRO_TWIN_LocalRefTorque

MPRO_TWIN_LocalActTorque scaled Int16

P 2598 0 scaled Int16

P 2599 0

MPRO_TWIN_LocalRefSpeed

MPRO_TWIN_LocalActSpeed scaled

scaled torque setpoint (local)

scaled torque actual value

(local)

scaled speed setpoint (local)

scaled speed actual value Int16

Table 4.8: Frequently used parameters for transmitting process data

Loading...

Loading...