Specification TWINsync module

14

4 Description of parameters

ID no.: CB08759-001Date: 03/2023

moog

4.1.1 Master/Slave Selector (P 2614) TOPT_TWIN_

Mode

The TWINsync slave synchronizes wi

th the TWINsync master via the TWINsync

interface. This means that one of the drives must be parametrised as the TWINsync

master and one as the TWINsync slave. The parameter (P2614) TOPT_TWIN_Mode

is for defining the master/slave operation mode.

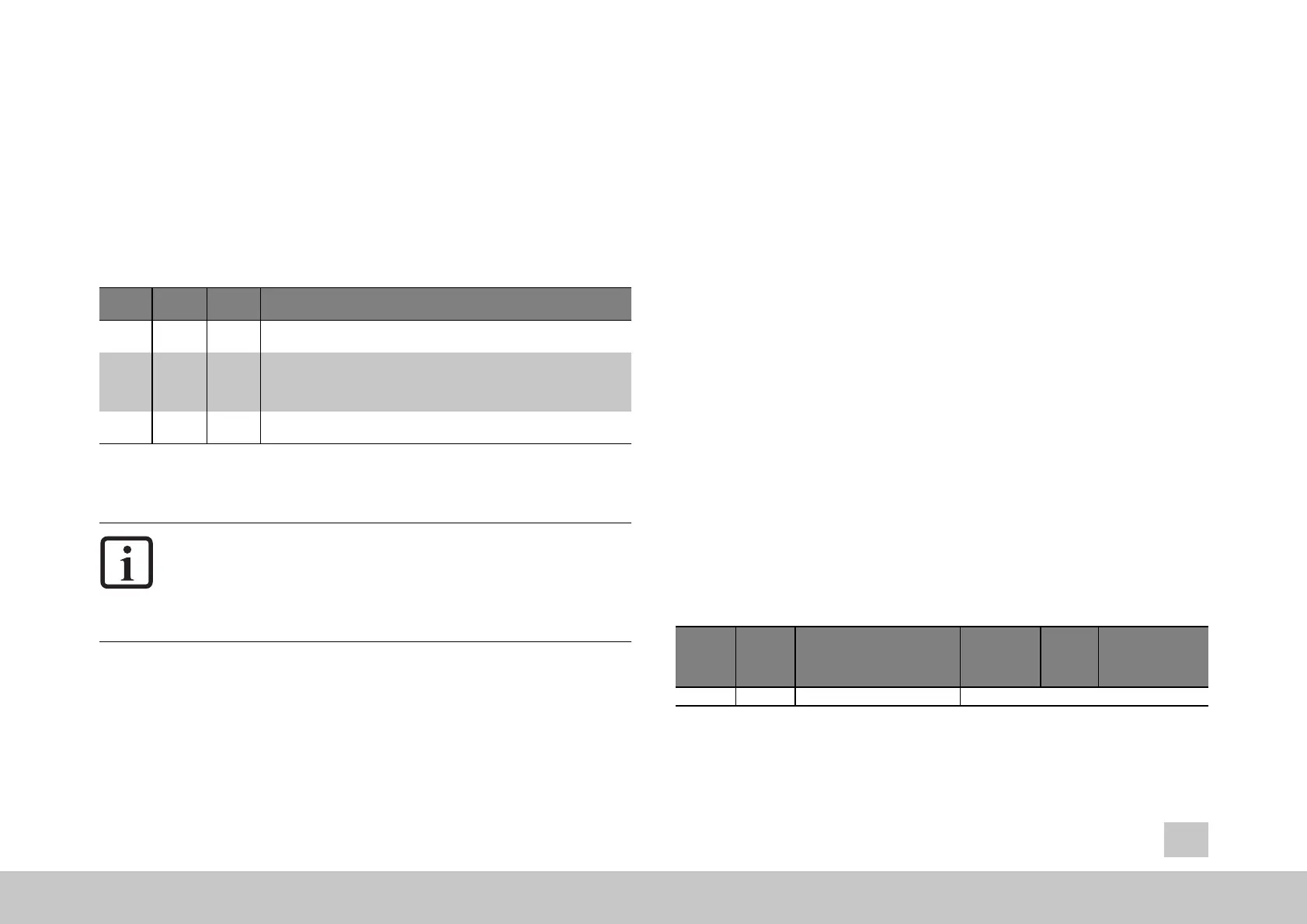

ID

Selection

text

Value Description

P 2614 OFF 0 The selection OFF disables the TWINsync interface. In the OFF state, no

process data are sent and no SYNC OUT signal is generated.

SLAVE 1

The selection SLAVE puts the MSD Servo Drive into the TWINsync slave

mode. The slave drive synchronizes its controller cycle with the incoming

SYNC

IN signals. If the SYNC IN signal remains absent for a configurable

time, a communication error is reported (see the next section).

MASTER 2

The selection MASTER puts the MSD Servo Drive into the TWINsync master

mode. SYNC OUT signals are generated for the slave.

Table 4.2: Setting options for (P2614) TOPT_TWIN_Mode

NOTE:

It is mandatory for the synchronization that both dri

ves be set for the same

switching frequency because this is used for the synchronization. This

means that the parameter (P0302) CON_SwitchFreq must be set to the

same value for both axes.

4.1.2 Timeout monitoring for the communication

A communication interface fault is recognized as follows:

l The MSD Servo Drive receives invalid data (CRC monitoring)

l The TWINsync master synchronization signal is not sent.

If one of these error occurs, it is assumed that the transmission channel is

malfunctioning. The parameter (P2613) TOPT_TWIN_MaxFaultTime specifies for

w

hat time interval (in ms) the channel can be considered to be malfunctioning

without an error being reported. This monitoring is not enabled in the extended

mapping mode. The monitoring of valid frames can be performed in this use case

with the corresponding scope signals, for example in the MSD PLC. If there is a fault,

the last correctly received data are frozen. The error messages are documented in

the chapter " Monitoring functions / Error messages" on page 41.

For commissioning, it is therefore recommended that ma

ster and slave be

configured and then an initialization be forced, or a restart of the devices be carried

out (P0149) MPRO_DRVCOM_Init). It is possible to check for valid or invalid

communication by means of scope variables ID-5709 (TWIN_FrameValid) or ID-

5710 (TWIN_FrameErrorCounter).

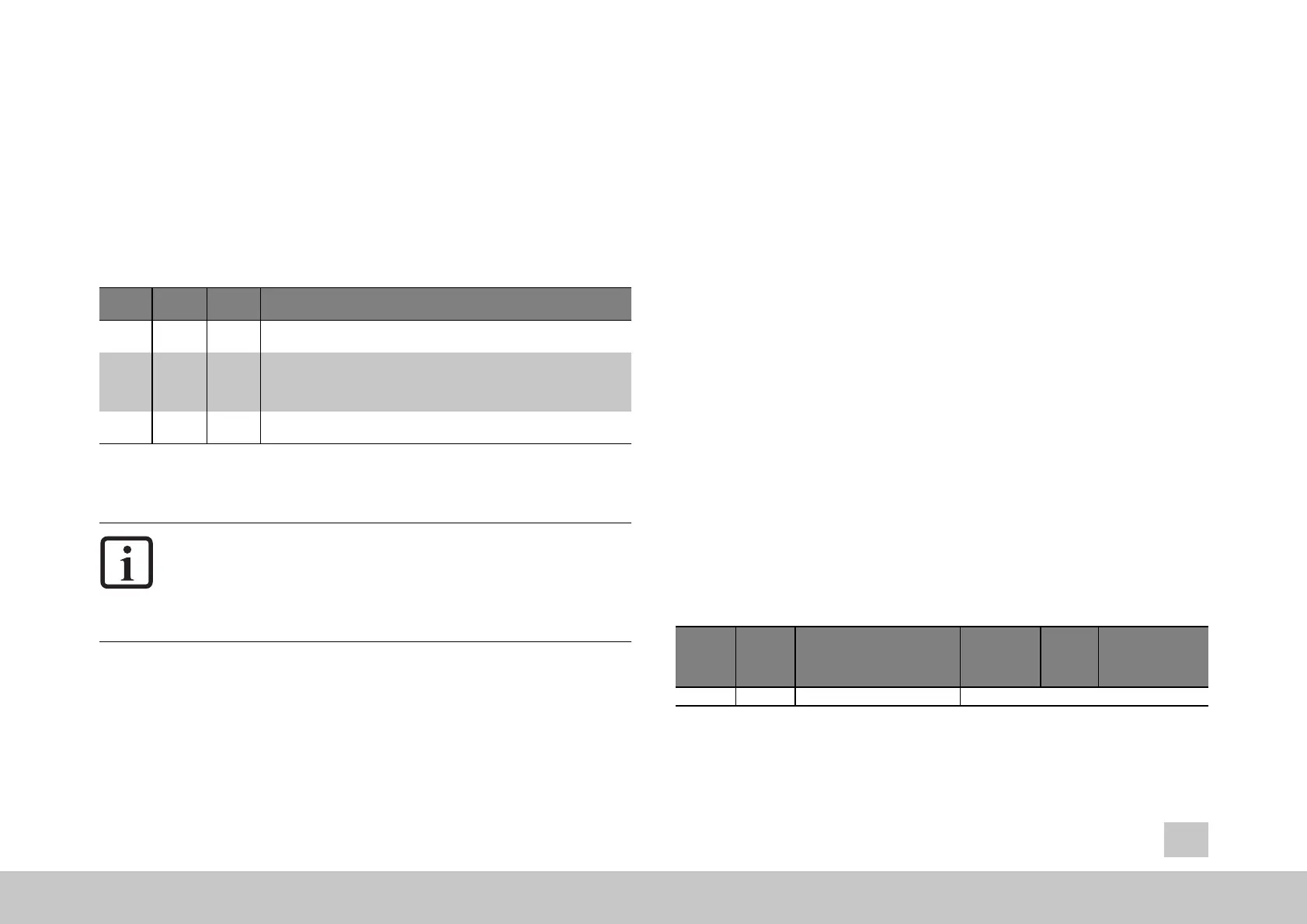

4.1.3 Structure of a TWINsync data telegram

A TWINsync data telegram in the standard-mapping mode is structured

as shown in

the table below. It consists of 3x2 bytes of fixed data (16-bit CRC, 16-bit TWINsync

status word and a control word or status word for changing the slave device state)

followed by a variable number of bytes of process data, or PDOs (process data

objects). The TWINsync data telegram example in the table is shown with 10 bytes

for PDO data for a total frame length of 16 bytes. This is accomplished with the setting

parameter Framesize = 0 (== (P2709) TOPT_TWIN_PhyLinkConfig[1]).

Checksum

(fixed)

TWINsync

status

word

(fixed)

PDO1 (con-

figurable)

...

PDOn (con-

figurable)

2 bytes 2 bytes

Control or status word

(DRIVECOM) (fixed)

2 bytes 10 bytes

Table 4.3: TWINsync data telegram (standard mapping)

Loading...

Loading...