24

Temposonics

®

R-Series SSI

Operation Manual

Temposonics

®

R-Series SSI

Operation Manual

Controlling design dimensions are in millimeters and measurements in ( ) are in inches

4.4.1 Installation of RD4 with threaded flange

Fix the sensor rod via threaded flange M18×1.5-6g or ¾"-16 UNF-3A.

Hydraulics sealing

There are the following ways to seal the flange contact surface (Fig. 17):

For threaded flange »C« / »D«:

1. A sealing by using an O-ring (e.g. 22.4 × 2.65 mm (0.88 × 0.1 in.),

25.07 × 2.62 mm (0.99 × 0.1 in.)) in a cylinder end cap groove.

For threaded flange (¾"-16 UNF-3A) »D« / »T«:

2. A sealing by using an O-ring 16.4 × 2.2 mm (0.65 × 0.09 in.)

(part no. 560 315) in the undercut.

For threaded flange (M18×1.5-6g) »C« / »M« & »G«:

3. A sealing by using an O-ring 15.3 × 2.2 mm (0.6 × 0.09 in.)

(part no. 401 133) in the undercut. In this case, a screw hole based

on ISO 6149-1 (Fig. 18) must be provided. See ISO 6149-1 for further

information.

• Note the fastening torque of 50 Nm.

• Seat the flange contact surface completely on the cylinder mounting

surface.

• The cylinder manufacturer determines the pressure-resistant gasket

(copper gasket, O-ring, etc.).

• The position magnet should not grind on the sensor rod.

• The piston rod drilling (≥ Ø 13 mm (≥ Ø 0.51 in.)) depends on the

pressure and piston speed.

• Adhere to the information relating to operating pressure.

• Protect the sensor rod against wear.

Fig. 16: Mounting example of threaded flange »C «/ »D«, »M« / »T« & »G«

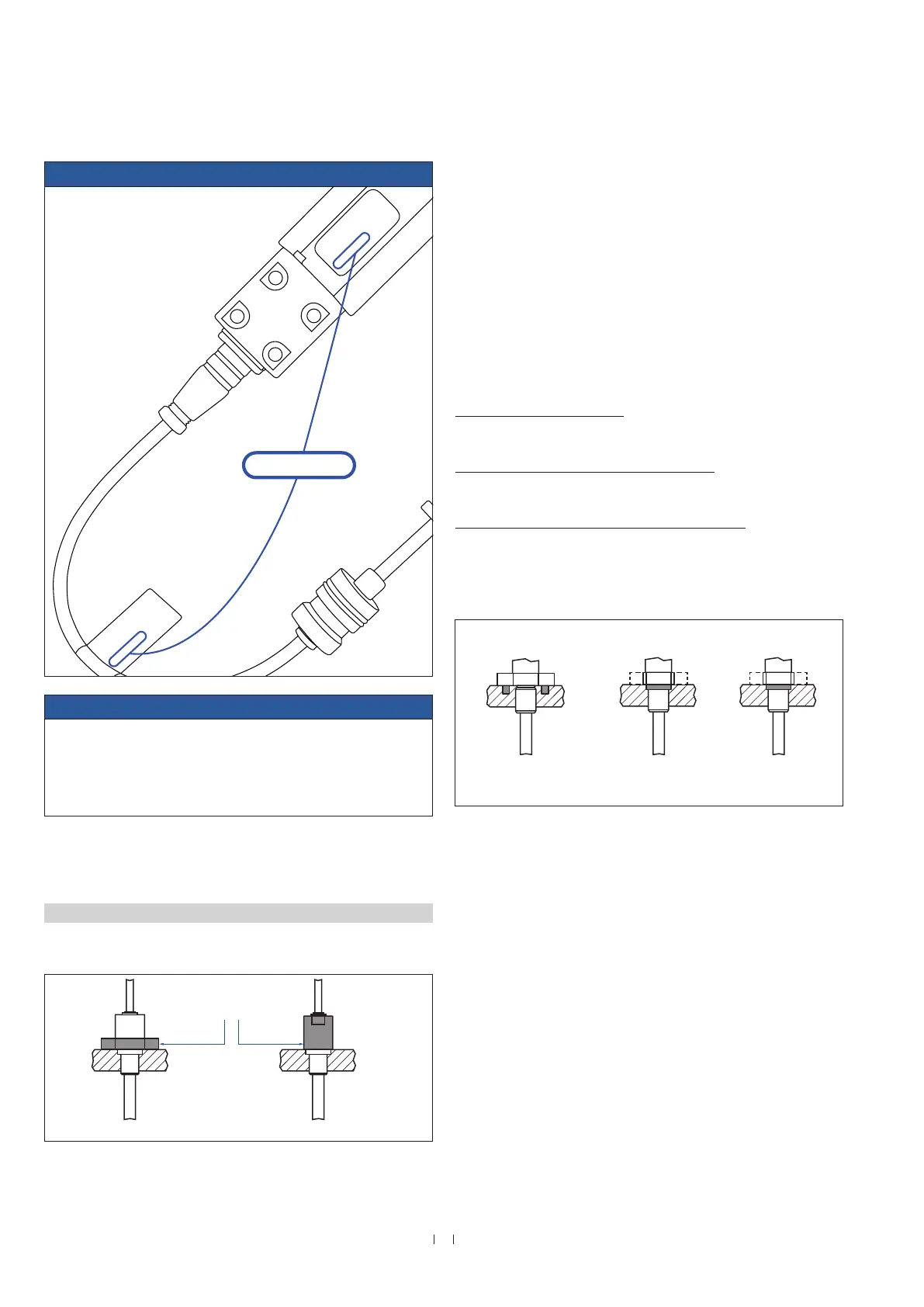

Fig. 17: Possibilities of sealing

NOTICE

RD4MD2S0150D70S1G2100

0.01 mm / 25 Bit gray

Grd.: 2797.14 m/s

FNr.: 1413 3950

14133950141339501413395014133950

RD4MD2S0150D70S1G2100

0.01 mm / 25 Bit gray

Grd.: 2797.14 m/s

FNr.: 1413 3950

14133950141339501413395014133950

FNr.: 1413 3950

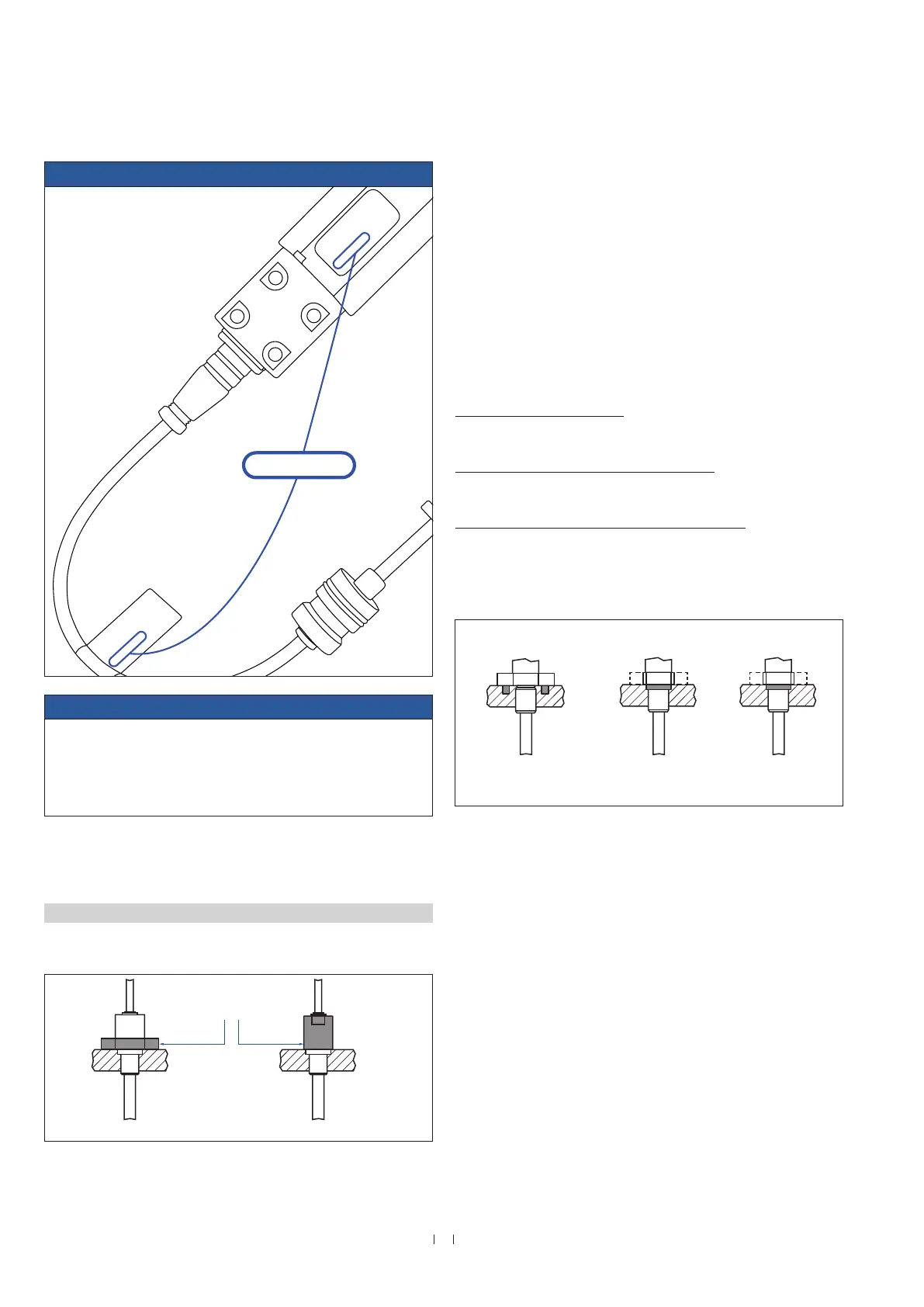

Note for installation respectively

for replacement

The serial numbers (FNr. / S/N) of

cable and sensor electronics housing

must match, so that the position

measurement is correct.

Serial number

example

NOTICE

Mount the sensor as follows:

1. Mount the flange with sensor rod

2. Mount the sensor electronics housing

3. Connect the cable between flange and the sensor electronics

housing

The steps mentioned above will be explained in chapter 4.4.1, chapter

4.4.2 and chapter 4.4.3.

Installation of a rod-style sensor in a fluid cylinder

The rod-style version has been developed for direct stroke

measurement in a fluid cylinder. Mount the sensor via threaded flange

or a hex nut.

• Mounted on the face of the piston, the position magnet travels

over the rod without touching it and indicates the exact position

through the rod wall – independent of the hydraulic fluid.

• The pressure resistant sensor rod is installed into a bore in the

piston rod.

Threaded flange »M« / »T«, »G«Threaded flange »C« / »D«

Fastening torque

50 Nm

Sealing via O-ring

e.g. 22.4 × 2.65 (0.88 × 0.1)

in cylinder end cap groove

For threaded flange

»C« / »D«

Sealing via O-ring

16.4 × 2.2 (0.65 × 0.09)

in the flange undercut

For threaded flange

»D« / »T«

Sealing via O-ring

15.3 × 2.2 (0.6 × 0.09)

in the flange undercut

For threaded flange

»C« / »M« & »G«

Loading...

Loading...