29

Temposonics

®

R-Series SSI

Operation Manual

Temposonics

®

R-Series SSI

Operation Manual

4.5.1 Installation of RT4 with threaded flange

Fix the sensor rod via threaded flange M18×1.5-6g or ¾"-16 UNF-3A.

Hydraulics sealing

There are two ways to seal the flange contact surface (Fig. 27):

1. A sealing by using an O-ring (e.g. 22.4 × 2.65 mm (0.88 × 0.1 in.),

25.07 × 2.62 mm (0.99 × 0.1 in.)) in a cylinder end cap groove.

2. A sealing by using an O-ring in the undercut.

For threaded flange (¾"-16 UNF-3A) »D« / »T«:

O-ring 16.4 × 2.2 mm (0.65 × 0.09 in.) (part no. 560 315)

For threaded flange (M18×1.5-6g) »M«:

O-ring 15.3 × 2.2 mm (0.60 × 0.09 in.) (part no. 401 133)

In this case, a screw hole based on ISO 6149-1 must be provided

(Fig. 28). See ISO 6149-1 for further information.

• Note the fastening torque of 50 Nm.

• Seat the flange contact surface completely on the cylinder mounting

surface.

• The cylinder manufacturer determines the pressure-resistant gasket

(copper gasket, O-ring, etc.).

• The position magnet should not grind on the sensor rod.

• The piston rod drilling (≥ Ø 13 mm (≥ Ø 0.51 in.)) depends on the

pressure and piston speed.

• Adhere to the information relating to operating pressure.

• Protect the sensor rod against wear.

Notice for metric threaded flanges

Fig. 26: Mounting example of threaded flange »D« / M« & »T«

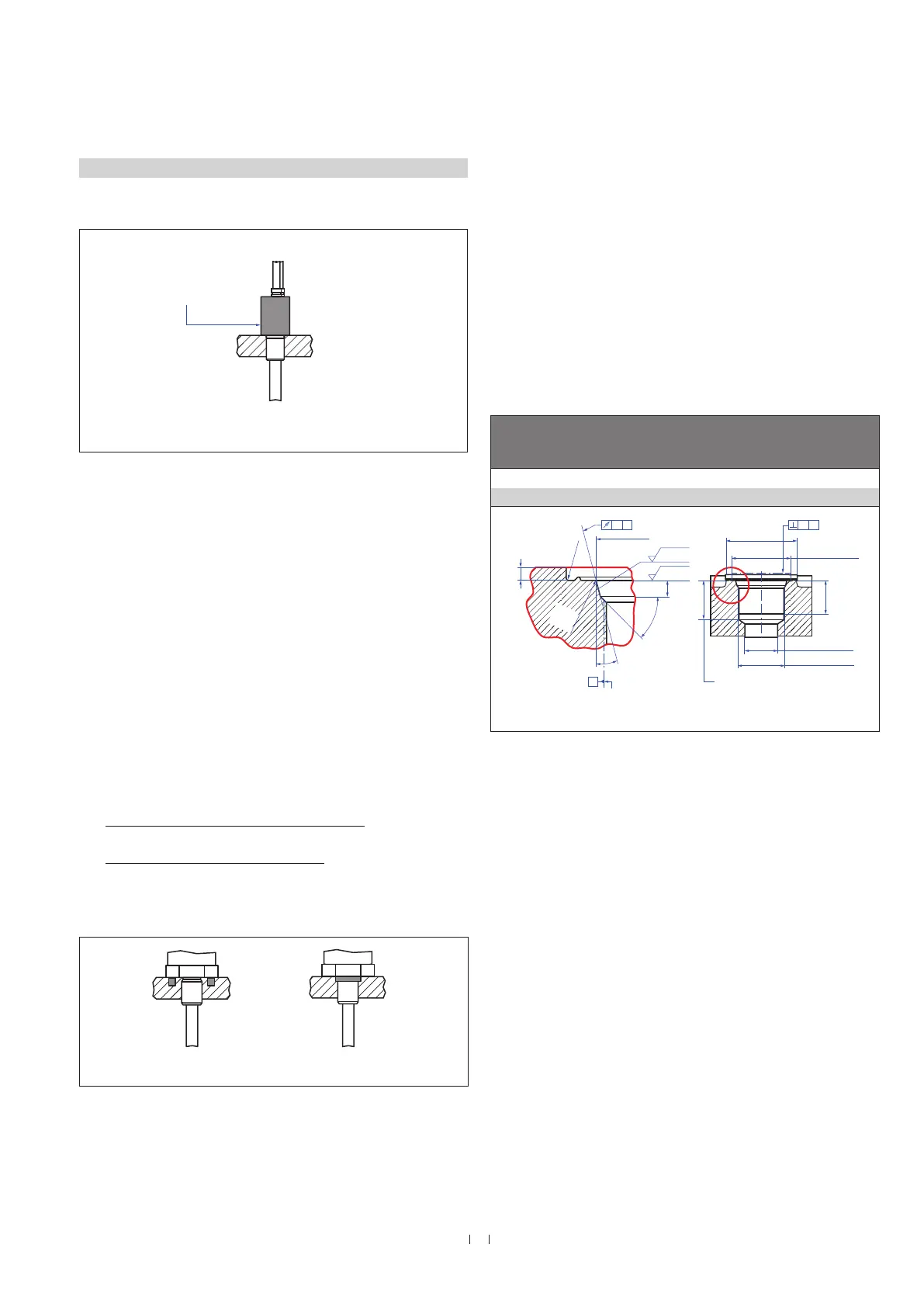

Fig. 27: Possibilities of sealing

Fig. 28: Notice for metric threaded flange M18×1.5-6g based on DIN ISO 6149-1

Controlling design dimensions are in millimeters

Thread

(d

1

×P)

d

2

d

3

d

4

d

5

+0.1

0

L

1

+0.4

0

L

2

L

3

L

4

Z°

±1°

RT4-M

M18×1.5-6g 55 13 24.5 19.8 2.4 28.5 2 26 15°

Ød

5

Ra 3.2

Ra 3.2

Pitch diameter

A

A

Thread

(d

1

× P)

Ød

3

(Reference)

A

Ød

2

Ød

4

(Gauging)

This dimension applies when

tap drill cannot pass through

entire boss.

≤ R0.4

R0.3

R0.1

Z°

4

5

°

±

5

°

3

L

1

L

2

L

4

A0.1 A0.2

Installation of a rod-style sensor in a fluid cylinder

The rod-style version has been developed for direct stroke

measurement in a fluid cylinder. Mount the sensor via threaded flange

or a hex nut.

• Mounted on the face of the piston, the position magnet travels

over the rod without touching it and indicates the exact position

through the rod wall – independent of the hydraulic fluid.

• The pressure resistant sensor rod is installed into a bore in the

piston rod.

Threaded flange »D« / »M«, »T«

Fastening torque

50 Nm

Sealing via O-ring

Sealing via O-ring

in cylinder end cap groove

Loading...

Loading...