ENGINE

03-M-E3B, 03-M-DI-E3B, 03-M-E3BG, WSM

1-S97

(5) Cylinder

Cylinder Wear

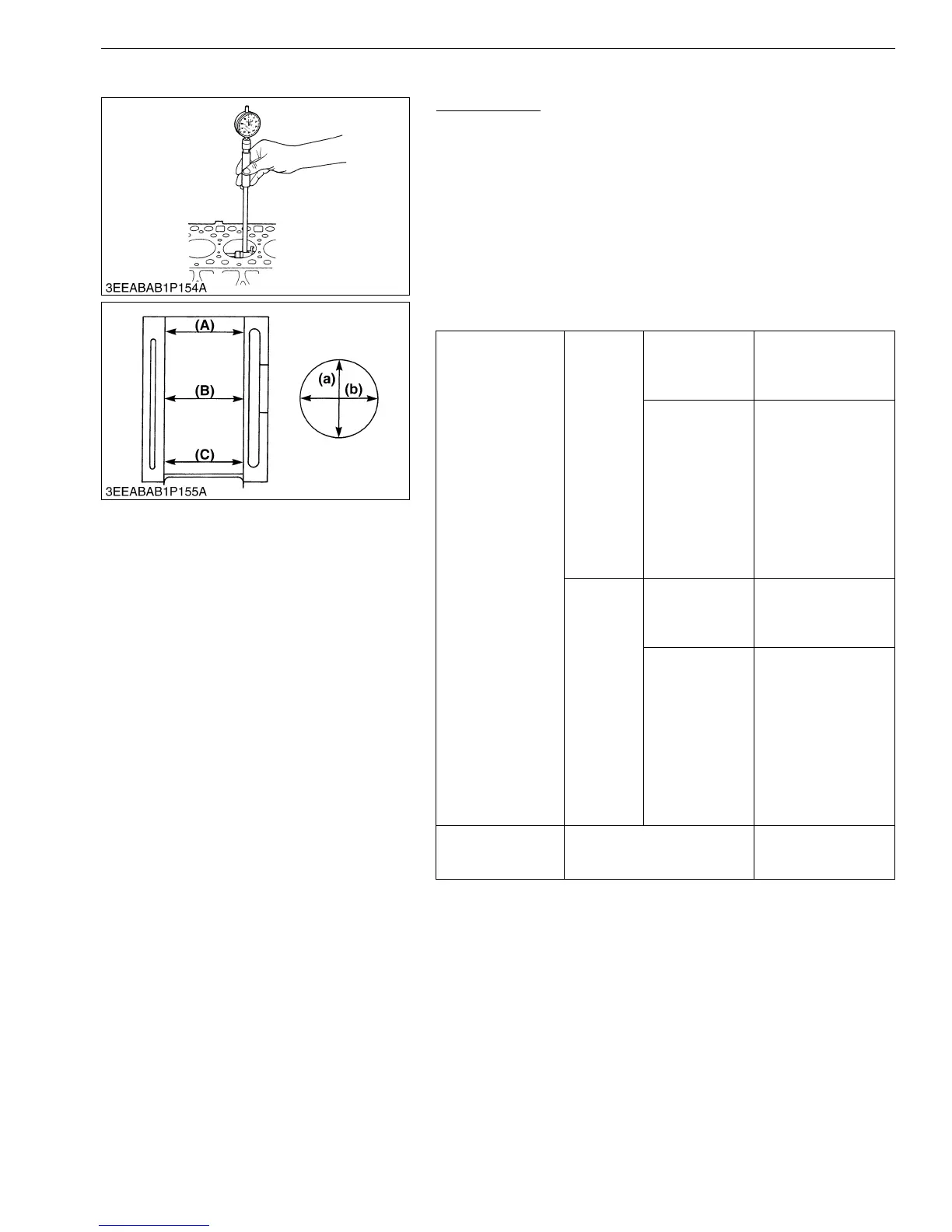

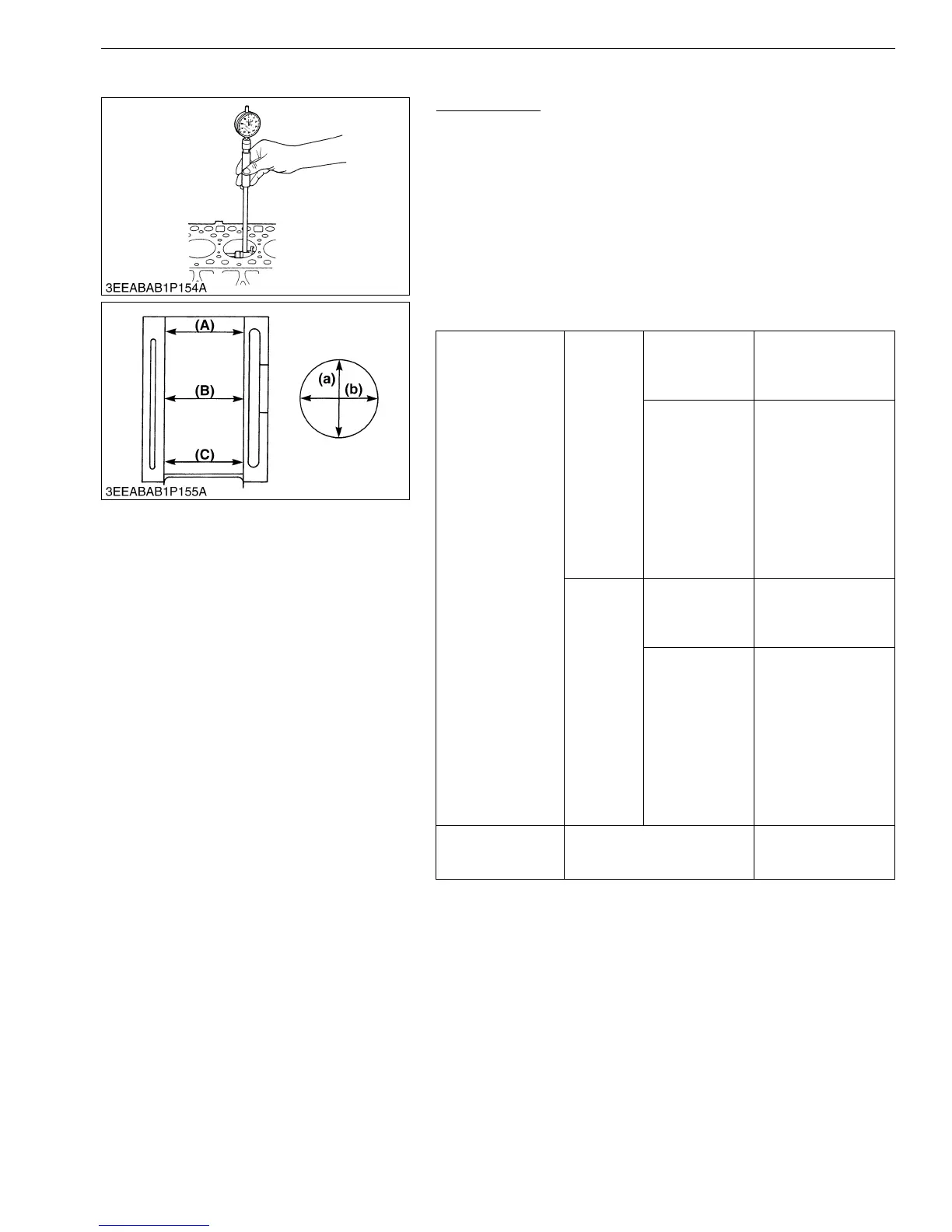

1. Measure the I.D. of the cylinder at the 6 positions (see figure)

with a cylinder gauge.

2. Find the maximum and minimum inner diameters.

3. Find the difference between the maximum and the minimum

inner diameters.

4. If the maximum I.D. or the difference is more than the allowable

limit, bore and hone it to the oversize dimension. (Refer to

"Cylinder Correction (Oversize)".).

5. Examine the cylinder wall for scratches. If you find deep

scratches, bore the cylinder. (Refer to "Cylinder Correction

(Oversize)".)

M00000003ENS0143US1

Cylinder I.D.

Factory

spec.

D1503-M

V2003-M

V2003-M-BG

V2003-M-T-BG

83.000 to 83.022 mm

3.2678 to 3.2685 in.

D1703-M

D1803-M

V2203-M

V2403-M

V2403-M-T

D1803-M-DI

V2403-M-DI

V2403-M-DI-T

D1703-M-BG

V2203-M-BG

V2403-M-BG

87.000 to 87.022 mm

3.4252 to 3.4260 in.

Allowable

limit

D1503-M

V2003-M

V2003-M-BG

V2003-M-T-BG

83.170 mm

3.2744 in.

D1703-M

D1803-M

V2203-M

V2403-M

V2403-M-T

D1803-M-DI

V2403-M-DI

V2403-M-DI-T

D1703-M-BG

V2203-M-BG

V2403-M-BG

87.170 mm

3.4319 in.

Difference between

maximum I.D. and

minimum I.D.

Allowable limit

0.15 mm

0.0059 in.

(A) Top

(B) Middle

(C) Bottom (Skirt)

(a) Right-angled to Piston Pin

(b) Piston Pin Direction

Loading...

Loading...