ENGINE

03-M-E3B, 03-M-DI-E3B, 03-M-E3BG, WSM

1-S100

Commutator and Mica

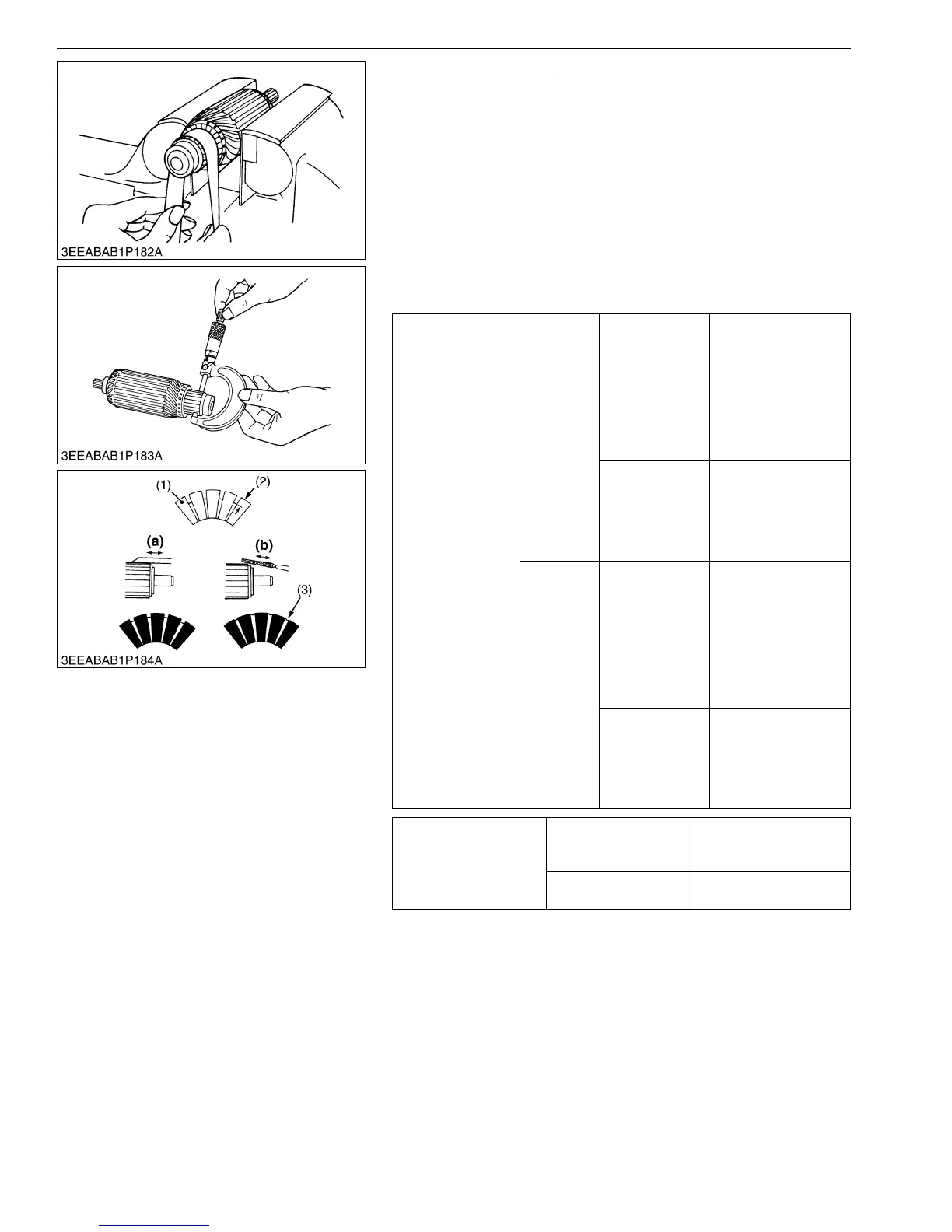

1. Examine the contact of the commutator for wear, and grind the

commutator with emery paper if it is lightly worn.

2. Measure the commutator O.D. with an external micrometer at

some points.

3. If the minimum O.D. is less than the allowable limit, replace the

armature assembly.

4. Calculate the difference of the outer diameters. If it is more than

the allowable limit, correct the commutator on a lathe to the

factory specification.

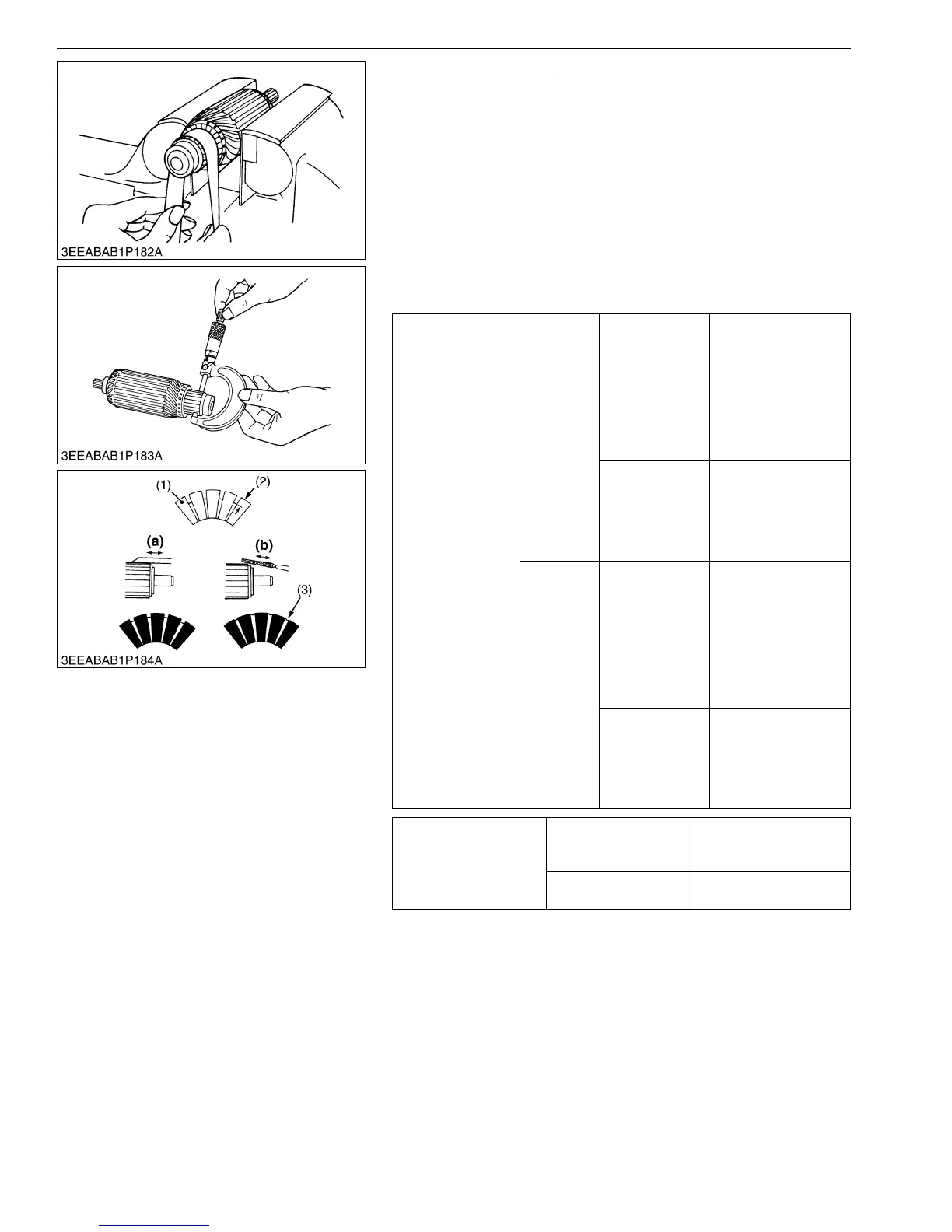

5. Measure the mica undercut.

6. If the undercut is less than the allowable limit, correct it with a

saw blade and chamfer the segment edges.

(To be continued)

Commutator O.D.

Factory

spec.

D1503-M,

D1703-M,

V2003-M,

V2203-M,

D1803-M-DI,

D1703-M-BG,

V2003-M-BG,

V2003-M-T-BG,

V2203-M-BG

30.0 mm

1.18 in.

D1803-M,

V2403-M,

V2403-M-T,

V2403-M-DI,

V2403-M-DI-T,

V2403-M-BG

35.0 mm

1.38 in.

Allowable

limit

D1503-M,

D1703-M,

V2003-M,

V2203-M,

D1803-M-DI,

D1703-M-BG,

V2003-M-BG,

V2003-M-T-BG,

V2203-M-BG

29.0 mm

1.14 in.

D1803-M,

V2403-M,

V2403-M-T,

V2403-M-DI,

V2403-M-DI-T,

V2403-M-BG

34.0 mm

1.34 in.

Difference of outer

diameters

Factory spec.

Less than

0.02 mm

0.0008 in.

Allowable limit

0.05 mm

0.002 in.

Loading...

Loading...