ENGINE

03-M-E3B, 03-M-DI-E3B, 03-M-E3BG, WSM

1-S69

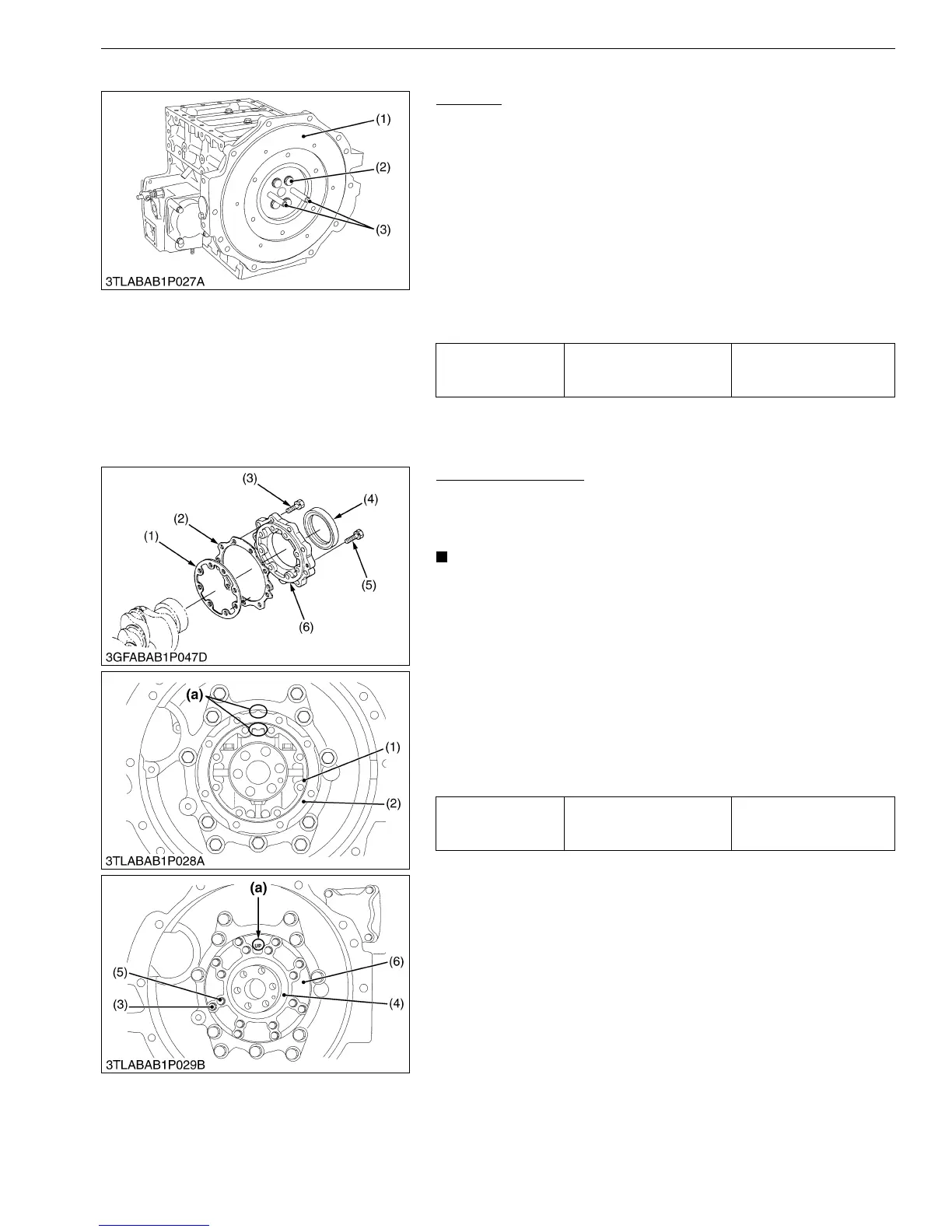

(6) Flywheel and Crankshaft

Flywheel

1. Attach the stopper to the flywheel (1).

2. Remove 2 flywheel screws (2).

3. Put the 2 flywheel guide screws (3) in the holes.

4. Remove all the flywheel screws (2).

5. Remove the flywheel (1) slowly along the flywheel guide screws

(3).

(When reassembling)

• Put in 2 flywheel guide screws (3).

• Examine that there are no metal particles that remain on the

flywheel mounting surfaces.

• Apply engine oil to the threads and the flange seat face of the

flywheel screw. Then attach the screw.

M00000003ENS0099US1

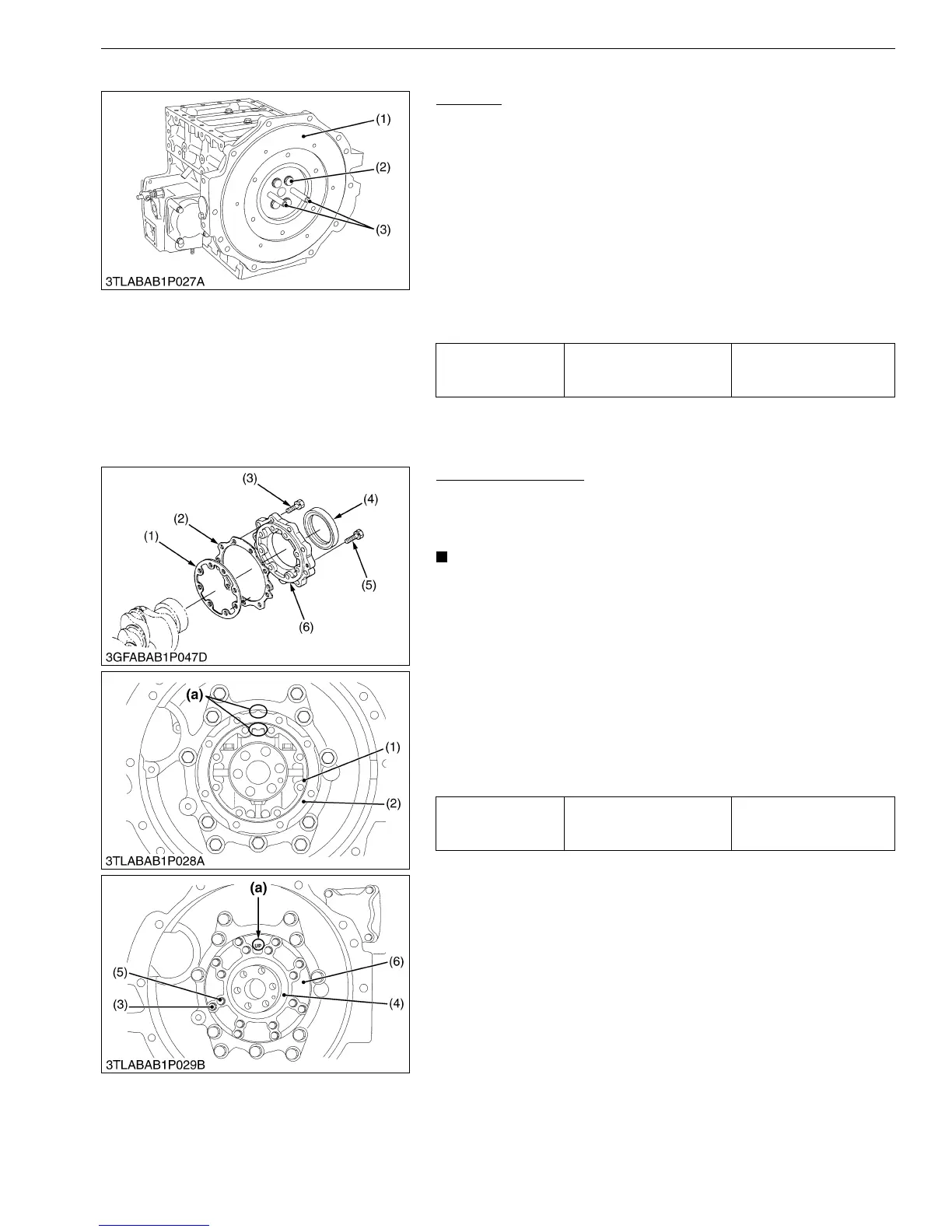

Bearing Case Cover

1. Remove the mounting screws of the bearing case cover. First,

remove inner screws (5) and then external screws (3).

2. Remove the bearing case cover (6).

• The length of inner screws (5) and external screws (3) are

different. Make sure that you use the correct one at the

correct position.

(When reassembling)

• Attach the bearing case gasket (1) and the bearing case cover

gasket (2) in the correct directions.

• Put the casting mark "UP" of the bearing case cover (6)

upward, then install the bearing case cover.

• Apply a thin layer of engine oil to the oil seal.

Then install the oil seal not to come off the lip.

• Tighten the mounting screws of the bearing case cover with an

equal force on the diagonal line.

M00000003ENS0100US1

Tightening torque Flywheel screw

98.1 to 107 N·m

10.0 to 11.0 kgf·m

72.4 to 79.5 lbf·ft

(1) Flywheel

(2) Flywheel Screw

(3) Flywheel Guide Screws

Tightening torque

Mounting screw of bearing

case cover

24 to 27 N·m

2.4 to 2.8 kgf·m

18 to 20 lbf·ft

(1) Bearing Case Gasket

(2) Bearing Case Cover Gasket

(3) Mounting Screw of Bearing Case

Cover

(4) Oil Seal

(5) Mounting Screw of Bearing Case

Cover

(6) Bearing Case Cover

(a) Upside

Loading...

Loading...