ENGINE

03-M-E3B, 03-M-DI-E3B, 03-M-E3BG, WSM

1-S22

4. CHECKING, DISASSEMBLING AND SERVICING

[1] CHECKING AND ADJUSTING

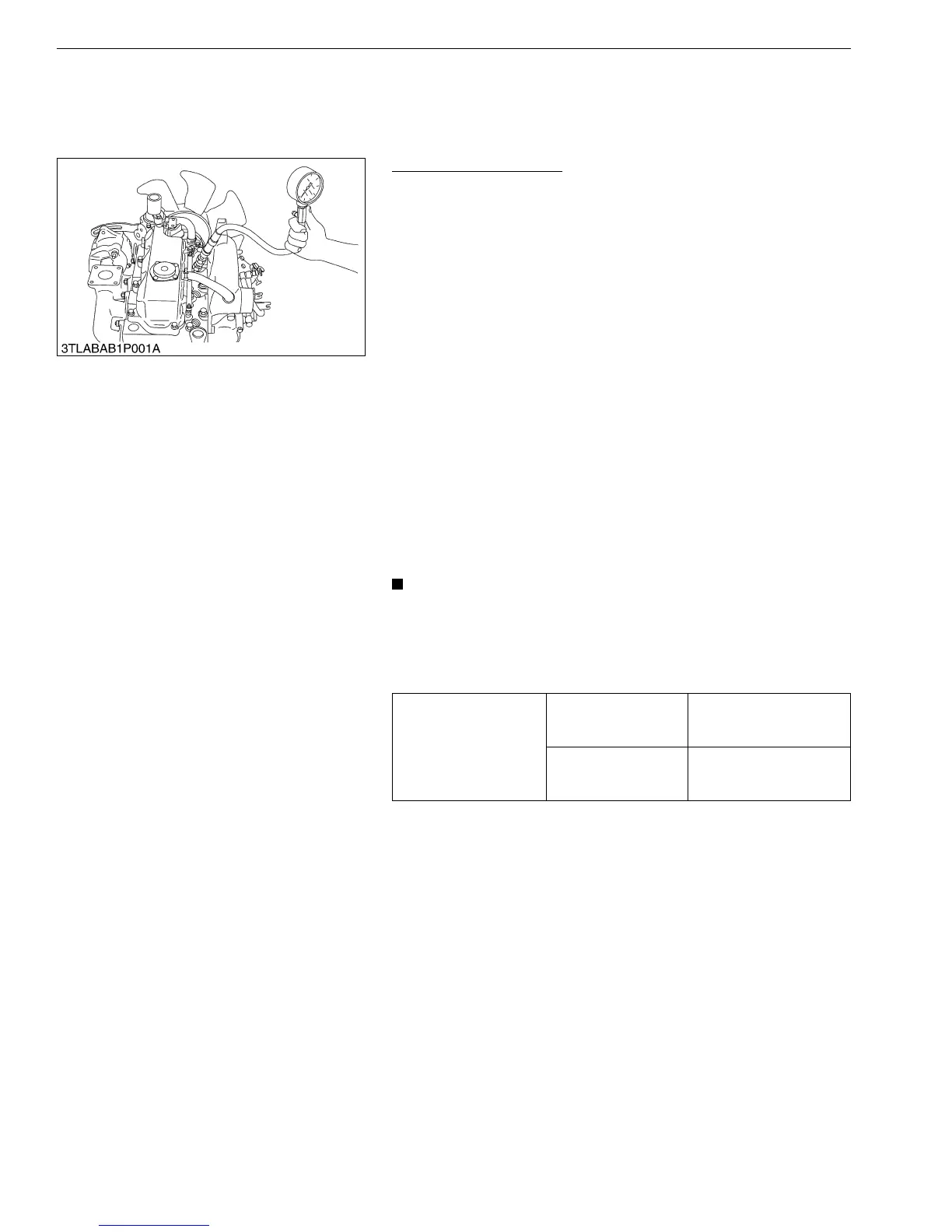

(1) Engine Body

Compression Pressure

[D1503-M, D1703-M, D1803-M, V2003-M, V2203-M, V2403-M,

V2403-M-T, D1703-M-BG, V2003-M-BG, V2003-M-T-BG,

V2203-M-BG, V2403-M-BG]

1. Operate the engine for warming-up.

2. Stop the engine.

3. Disconnect the 2P connector from the stop solenoid to stop the

fuel supply.

4. Remove the air cleaner, the muffler and all injection nozzles.

5. Set a compression tester with the adaptor to the nozzle hole.

6. Make sure that the stop lever is set at the stop position

(non-injection).

7. Crank the engine with the starter to measure the compression

pressure.

8. Do the steps 5 through 7 again for each cylinder.

9. If the measurement is below the allowable limit, apply a small

quantity of oil to the cylinder wall through the nozzle hole. Then

measure the compression pressure again.

10. If the compression pressure stays below the allowable limit,

examine the top clearance, valve and cylinder head.

11. If the compression pressure increases after you apply oil,

examine the cylinder wall and piston rings.

• Examine the compression pressure with the specified

valve clearance.

• Always use a fully charged battery for you do this test.

• Variances in cylinder compression values must be less

than 10 %.

M00000003ENS0016US1

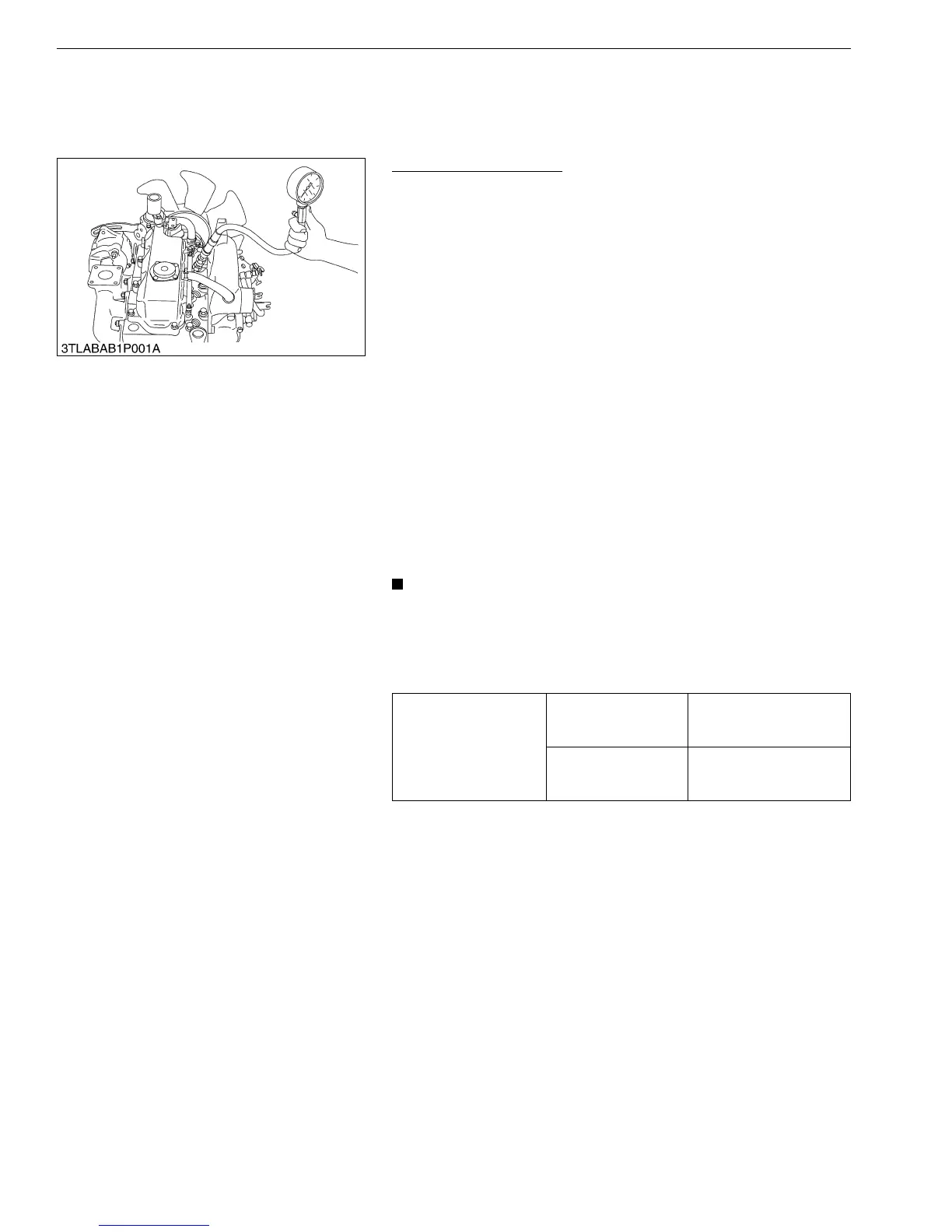

Compression pressure

Factory spec.

3.24 to 3.72 MPa

33.0 to 38.0 kgf/cm

2

470 to 540 psi

Allowable limit

2.55 MPa

26.0 kgf/cm

2

370 psi

Loading...

Loading...