4 – ENGLISH

INSTALLATION

3

3 INSTALLATION

3.1 PRE-INSTALLATION CHECKS

a

The installation must be carried out by qualied

personnel in compliance with the current legisla-

tion, standards and regulations, and with the in-

structions provided in this manual.

Before proceeding with the product’s installation, it is necessary to:

– check the integrity of the supply

– check that all the materials are in good working order and suited

to the intended use

– make sure that the structure of the door is suitable for being

automated

– make sure that the characteristics of the door fall within the op-

erating limits specied in the “Product usage limits” paragraph

(page 4)

– verify that there are no points of greater friction during the open-

ing and closing movements along the entire door path

– verify that the area where the gearmotor is installed allows for

unlocking the latter and manoeuvring easily and safely

– verify that the mounting positions of the various devices are pro-

tected against impacts and that the mounting surfaces are suf-

ciently sturdy

– prevent any parts of the automation from being immersed in wa-

ter or other liquids

– keep the product away from heat sources and open ames and

acid, saline or potentially explosive atmospheres; these may

damage the product and cause malfunctions or dangerous sit-

uations

– connect the control unit to an electricity supply line equipped

with a safety earthing system

– include a device on the electric power line ensuring complete

disconnection of the automation from the grid. The disconnec-

tion device must have contacts with a sufcient gap to ensure

complete disconnection, under the Category III overvoltage con-

ditions, in accordance with the installation instructions. Should it

be necessary, this device guarantees fast and safe disconnection

from the power supply; it must therefore be positioned in view of

the automation. If placed in a non-visible location, it must have a

system that blocks any accidental on unauthorised reconnection

of the power supply, in order to prevent dangerous situations.

The disconnection device is not supplied with the product.

3.2 PRODUCT USAGE LIMITS

The data relative to the product’s performances is included in the

“TECHNICAL SPECIFICATIONS” chapter (page 31) and is the

only data that allows for properly assessing whether the product is

suitable for its intended use.

Check the application limits of SPIDO and of the accessories to

be installed, assessing whether their characteristics are capable

of meeting the requirements of the environment and the limitations

specied below:

– the door dimensions must be below 10,5 m

2

– the weight of the door must not exceed 110 kg

– the wall-mounting bracket must be sufciently long.

Table 1

SPIDO - LIMITATIONS OF USE IN RELATION TO THE TYPE OF DOOR

Type of door Operating limits (m)

height width

Sectional 2,6 3,7

Non-protruding overhead door

(with accessory SPA5)

2,4 3,5

Protruding overhead door (with

accessory SPA5)

3 3,5

Overhead with springs (without

accessory SPA5)

3 3,5

The measurements shown in “Table 1” are purely indicative

and are only needed for making a rough estimate. The ac-

tual suitability of SPIDO for automating a specic door depends

on the degree of leaf balancing, guide friction and other aspects,

including occasional events such as wind pressure or the presence

of frost, which could obstruct the leaf’s movement.

To determine the actual conditions, the force required to move the

leaf throughout its path must be measured, to ensure that this val-

ue does not exceed the “rated torque” specied in the “TECHNI-

CAL SPECIFICATIONS” chapter (page 31).

a

The control unit is equipped with a manoeuvre lim-

iting device that prevents possible overheating; it is

based on the motor load and duration of the cycles,

and intervenes when the maximum limit is exceed-

ed.

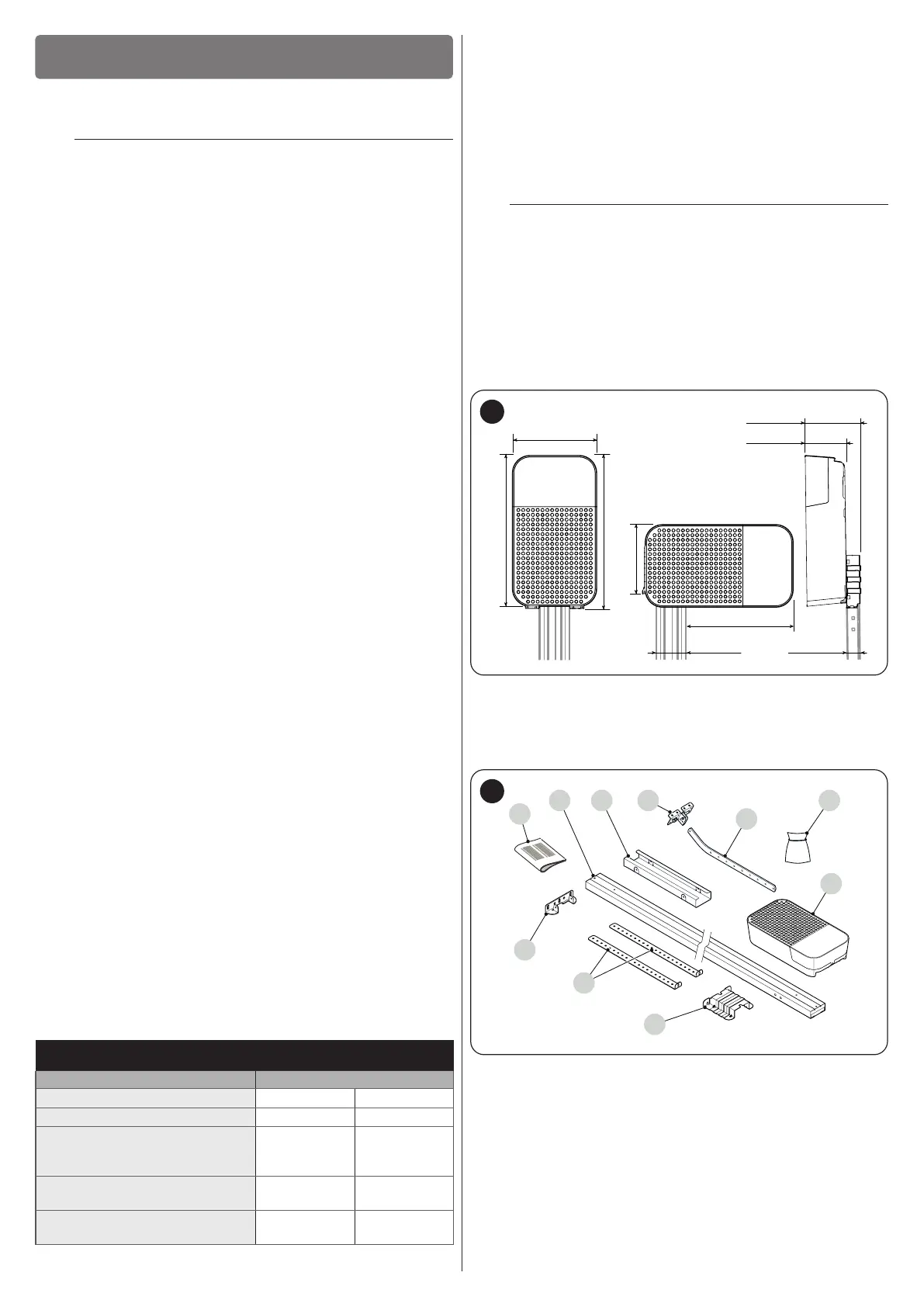

3.3 PRODUCT IDENTIFICATION AND OVERALL

DIMENSIONS

The overall dimensions of the product are shown in “Figure 3”.

161 mm

90 mm

70 mm 30 mm

192 mm

250 mm

350 mm

3

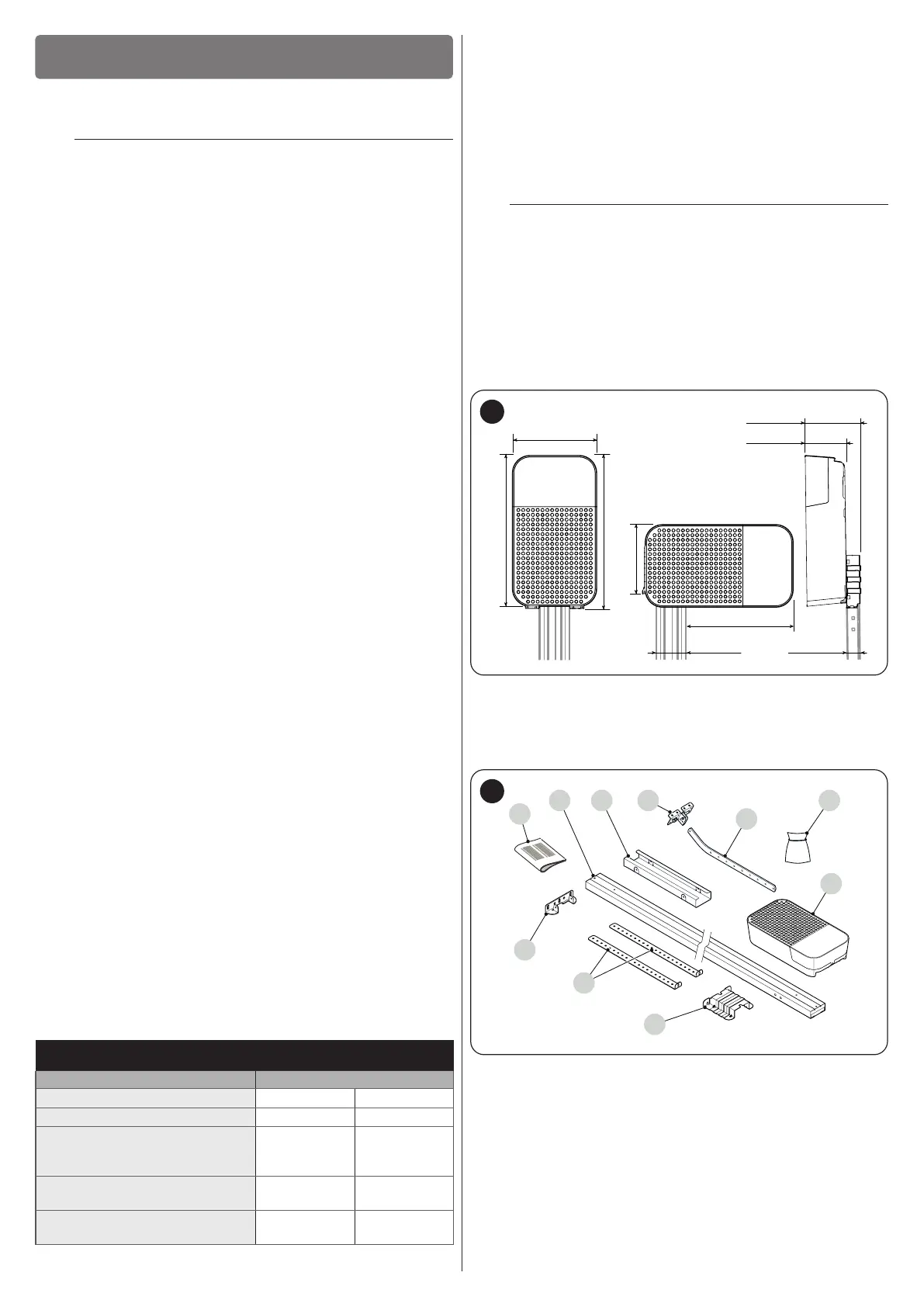

3.4 RECEIPT OF THE PRODUCT

All the components contained in the kit are illustrated and listed

below.

H

I

A

C

G

4

A Gearmotor

B Metal hardware (screws, washers, etc.)

C Drawbar

D Door mounting bracket

E Joining element for guide (in case of a 2-piece guide)

F Assembled / pre-assembled guide

G Quick guide

H Wall mounting bracket

I Ceiling mounting bracket

J Motor mounting bracket

Loading...

Loading...