14 – ENGLISH

5.3 AUTOMATIC FORCE SEARCH

The control unit requires this procedure after certain settings are

modied (e.g.: speed, opening and closing positions, tension re-

lease value, etc.) and is signalled by the ashing of the courtesy

light.

To start this procedure:

1. press one of these buttons to move the door (press

f

if the door is in the closing position, or

h

if it is in the opening position) (“Figure 38“)

DISPLAY

OPENCLOSE

38

2. an opening and closing manoeuvre (or inversely) will be car-

ried out automatically in succession so that the control unit

can assess the necessary force required for the subsequent

manoeuvres

m

These manoeuvres will be carried out with high

force. During their execution, check that there are

no assembly/adjustment defects or other anoma-

lies, for example points of excessive friction, and

solve them.

3. the procedure has been completed, the courtesy light (LC)

switches off.

m

It is important that the procedure is not interrupted,

for example with a STOP command or through an

intervention of the PHOTO. Should this occur, it can

be restarted by imparting a

f

or

h

command.

5.4 CHECKING THE DOOR MOVEMENT

After the automatic force learning procedure, it is advisable to carry

out a few manoeuvres in order to verify that the door moves prop-

erly.

To do this:

1. press the

f

button to command an opening ma-

noeuvre; verify that it occurs smoothly without any speed

variations; the door must slow down when it lies between 30

and 20 cm from the maximum opening set previously.

2. press the

h

button to command a closing manoeu-

vre; verify that it occurs smoothly without any speed varia-

tions; the door must slow down when it lies between 30 and

20 cm from the ground and stop when it comes into contact

with the oor. It will then perform a brief opening manoeuvre

to release the belt/chain tension (“Figure 39“)

DISPLAY

OPENCLOSE

39

3. during the manoeuvre, check that the warning light ashes

at intervals of 0.5 seconds on and 0.5 seconds off

4. open and close the gate several times to make sure that

there are no points of excessive friction and that there are no

defects in the assembly or adjustments

5. check that the gearmotor and guide are fastened in a sol-

id, stable and suitably resistant manner even during sudden

door acceleration or slowdown movements.

5.5 INVERTING THE DIRECTION OF MOTOR

ROTATION

The following procedure allows for modifying the motor’s direction

of rotation if the installation must be inverted.

l

This procedure is only available during the control

unit’s start phase.

To perform this procedure:

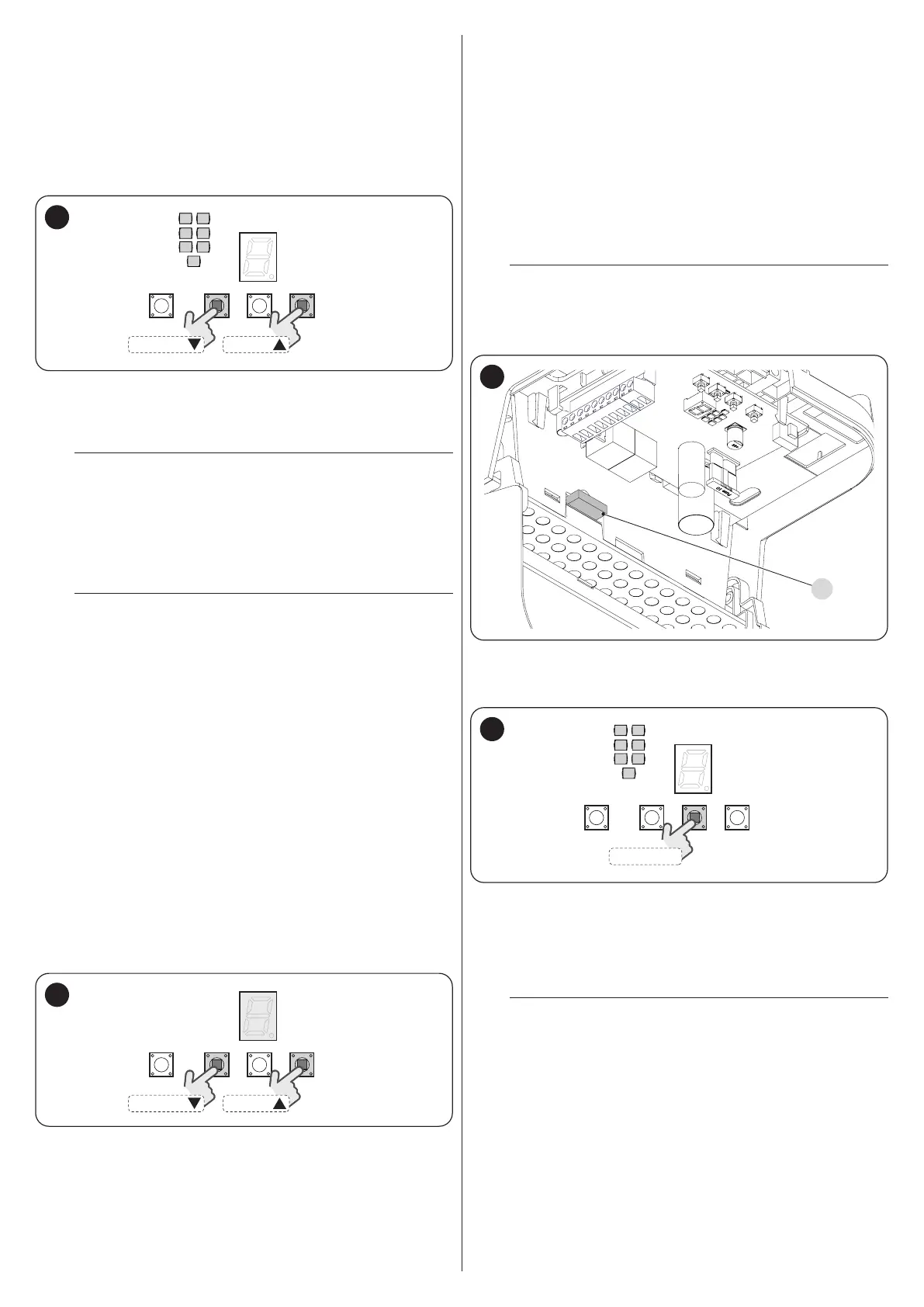

1. switch the control unit off and remove fuse F1 (“Figure 40“)

F1

40

2. press and hold the

g

button

3. reinsert the fuse: the control unit will switch on

4. release the

g

button after 3 seconds (“Figure 41“)

DISPLAY

STOP/SET

41

5. press the

g

button to modify the direction of rota-

tion which will shown by means of the courtesy light (LC):

– with the LC on, the rotation direction will be inverted

– with the LC off, the rotation direction will be standard

6. wait 3 seconds without pressing the buttons to conrm and

exit the programming mode.

m

After modifying the rotation direction it will be nec-

essary to rerun the position acquisition procedure

(consult the “Programming the door opening and

closing positions” chapter on page 12).

Loading...

Loading...