73

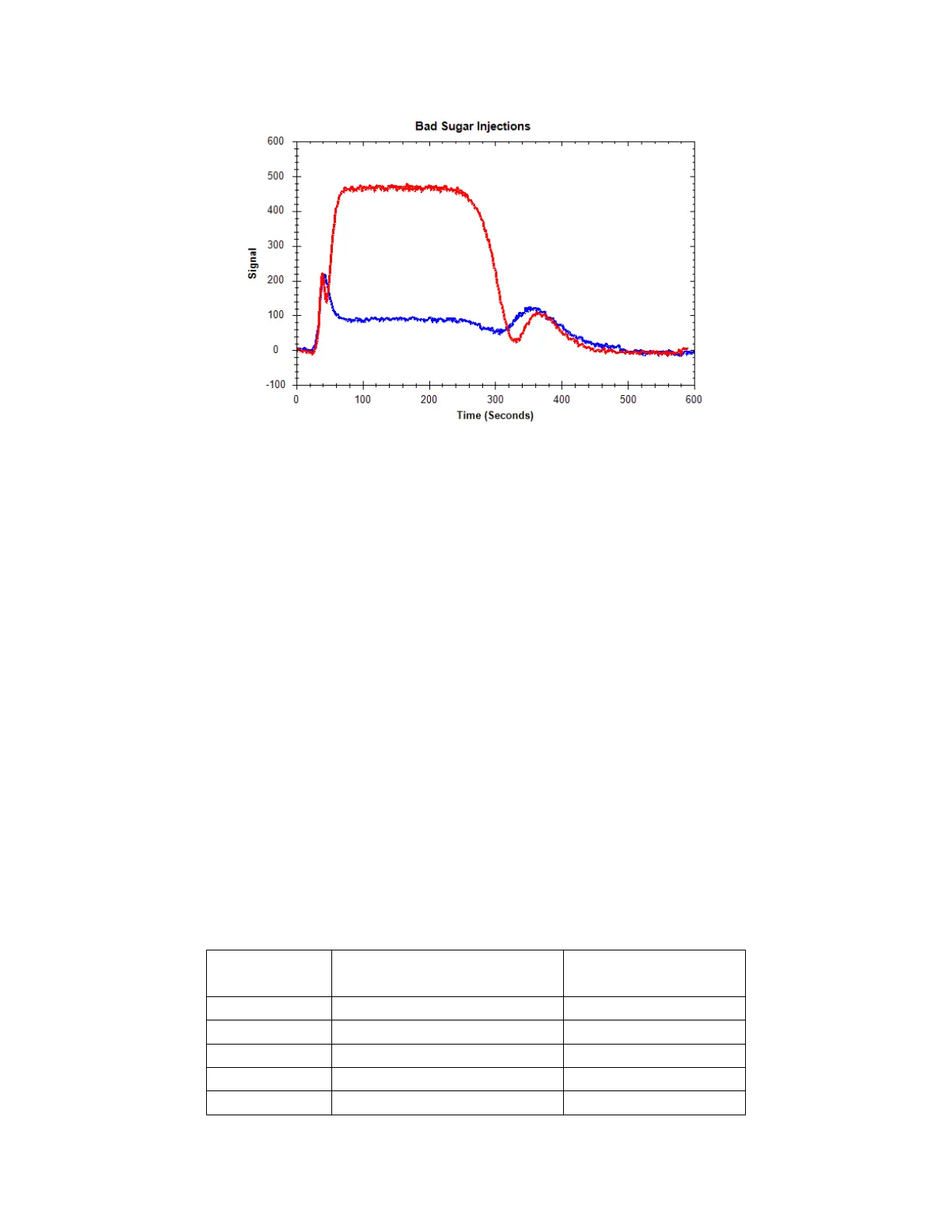

Figure 6.2 - Examples of bad sugar injections where bubbles were present in valve or flow cell.

6.2 Instrument Maintenance and Cleaning

To prevent clogging or contamination in future experiments it is recommended that deionized water

be pumped through the system after the day’s experiments are completed to prevent salt build up in

the lines. Purges with ethanol can also be performed for additional cleaning.

It is recommended to perform more in depth cleaning every 1-4 weeks depending on instrument

usage. The following cleaning procedure is recommended:

1. Load a clear glass chip (provided) or simply load a used Sensor Chip backwards so the sensor

is not in contact with the Flow Cell.

2. Use DI water as the running buffer, and follow the software prompts (reference spectra don’t

matter in this case), ensuring that Automatic Fill of Flow Cell is selected, which will run the

pump at max flow rate. Do not perform bubble prevention IPA injections (skip these steps).

3. In a 96-well plate, prepare 300 µL of 0.5% sodium dodecyl sulphate (SDS), 6 M urea, 1% acetic

acid and 0.2 M sodium bicarbonate solutions into separate wells. Enter the corresponding

sample information and well positions into the Sample Details screen with a pump speed of

25 µL/min for each sample.

4. Prepare the Test Timeline according to the following procedure:

Timepoint (s) to

proceed to next step

Loading...

Loading...