Operation

Application

Start Mode

Start Ramp

Time

Initial

Current

Current

Limit

Stop Mode

Stop Time

(seconds)

Fan - high pressure

Current

1 200 450

Coast To Stop

n/a

Mill - ball

Current

1 200 450

Coast To Stop

n/a

Mill - hammer

Current

1 200 450

Coast To Stop

n/a

Pump - bore

Adaptive

Control

(Const. accel.)

3 n/a 500

Adaptive

Control

(Const. decel.)

3

Pump - centrifugal

Control

(Const. accel.)

10 n/a 500

Control

(Const. decel.)

15

Pump - hydraulic

Current

2 200 350

Coast To Stop

n/a

Pump - positive

displacement

Control

(Const. accel.)

10 n/a 400

Control

(Const. decel.)

10

Pump - submersible

Control

(Const. accel.)

5 n/a 500

Control

(Const. decel.)

5

Saw - bandsaw

Current

1 200 450

Coast To Stop

n/a

Saw - circular

Current

1 200 350

Coast To Stop

n/a

Shredder

Current

1 200 450

Coast To Stop

n/a

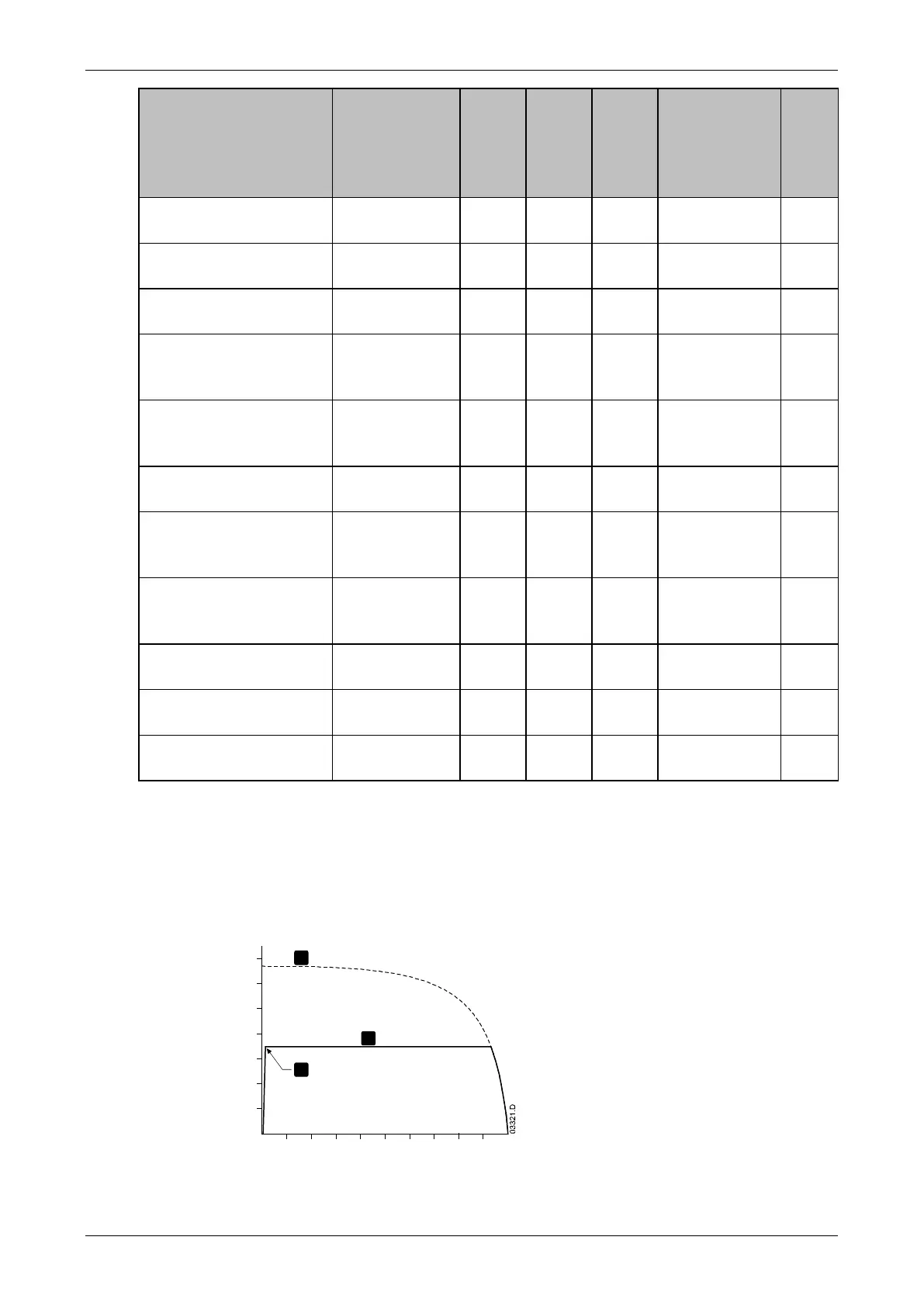

8.6 Soft Start Methods

Constant Current

Constant current is the traditional form of soft starting, which raises the current from zero to

a specified level and keeps the current stable at that level until the motor has accelerated.

Constant current starting is ideal for applications where the start current must be kept below

a particular level.

Current (%motor full load

current)

700%

600%

500%

300%

100%

400%

200%

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

1

3

2

1: Initial Current (parameter 2C)

2: Current Limit (parameter 2D)

3: Full voltage current

Rotor speed (% full speed)

38

Loading...

Loading...