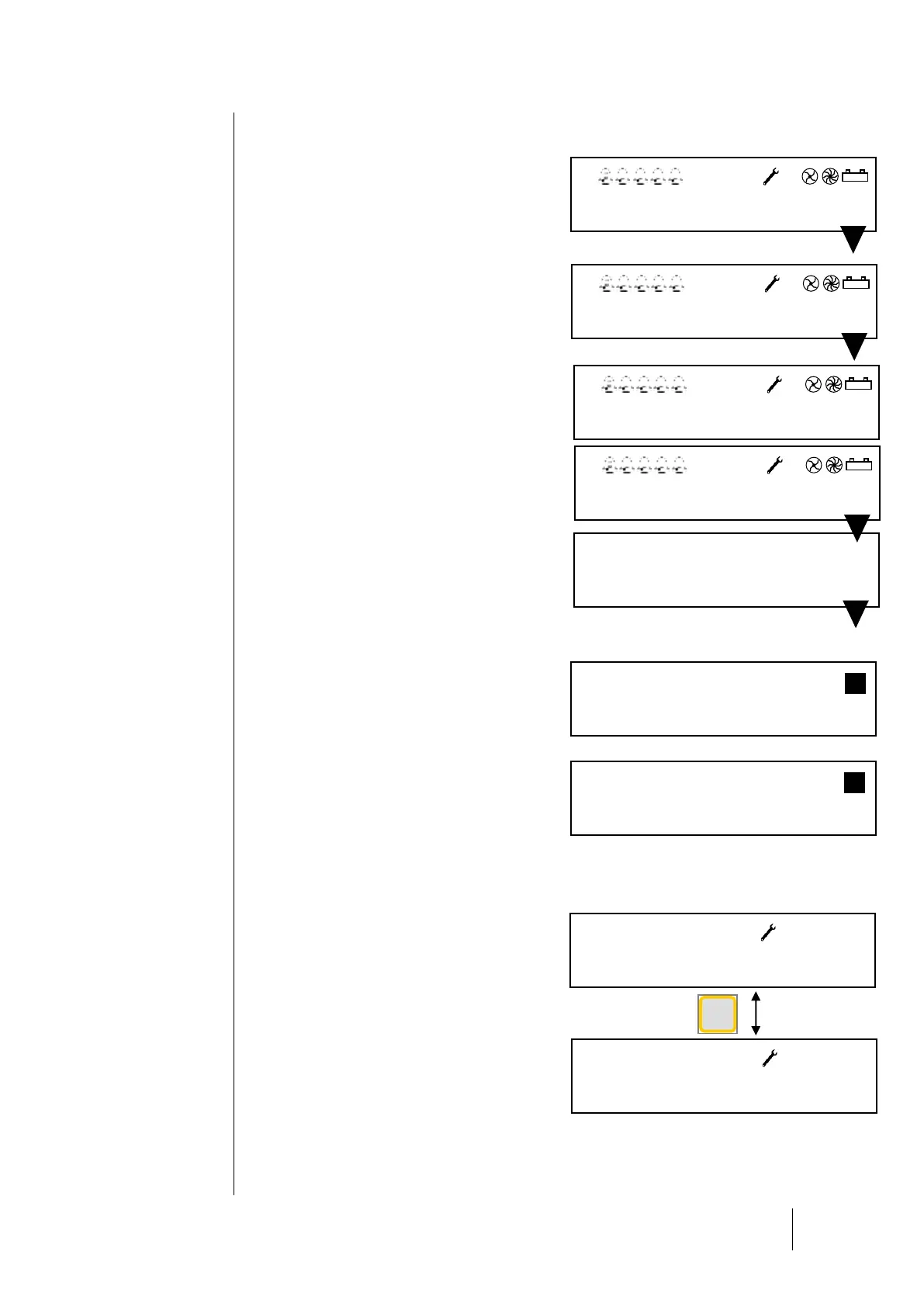

Start-up Phase

No faults or alarms are processed during the first

minute after start-up. During this phase, the

central controller runs a Checksum test (1), a

RAM test (2), a line start-up (3) and a module

mapping test with a program stored in its memory.

Voltage builds progressively in the lines. Progress

bars show the overall progress for line power-up.

Only the power-up of activated lines is shown

(identified by a diamond “ ” during the initial

power-up phase, and by a black square “ “ at

the end.)

An exclamation point “ ! “ indicates a short-circuit

line fault. The line can be reactivated through the

menu system.

Next, a sensor stabilization phase occurs (4)

during which time, the alarms are deactivated.

An inspection phase immediately follows in order

to verify that the configuration program set with

the COM_CPS software correctly maps to the

modules installed and activated.

If no errors are found, the program runs normally.

If errors are detected, the modules in question will

be flagged as faulting.

After the start-up phase, the screen will display

information pertaining to the selected mode:

events (a) or cyclic (b). The central controller

begins to process data coming in from the various

modules.

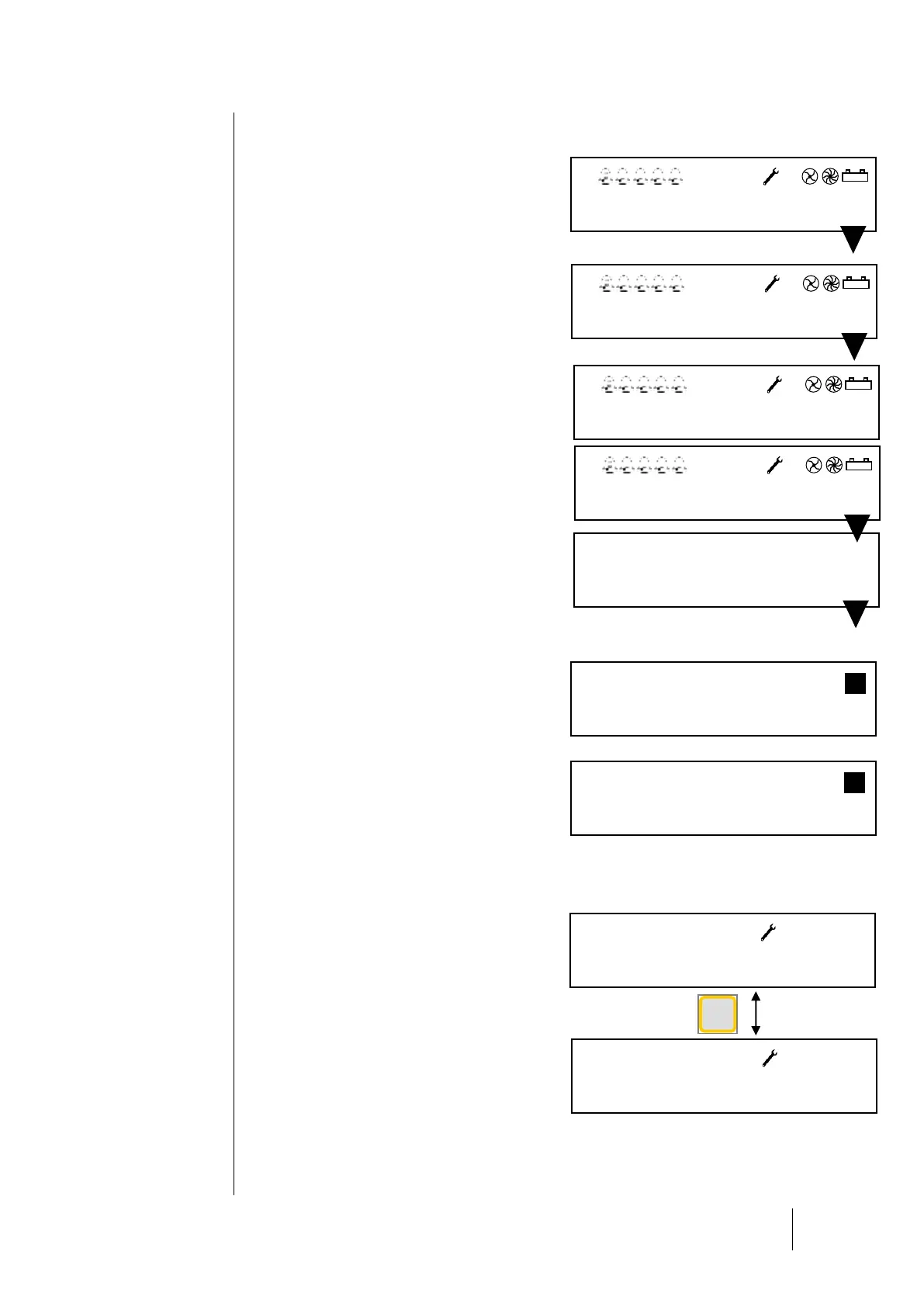

In cyclic display mode, when no alarms are

triggered the levels from each sensor are

displayed on the first line of the display screen.

In case of a power outage, the program

configuration will be saved. When the controller is

turned on, the last program installed by

COM_CPS will be loaded.

If a sensor faults, the message “Def” will replace

the reading value. If the power supply is

interrupted within a line, the two points in front of

that line will blink. Identify the problem by

touching the [ESC] key to display the error

message.

If the gas level exceeds a high or low threshold,

“Ovs” will appear on the display screen where the

value for that sensor would normally appear. This

message will display simultaneously with a

blinking arrow (pointing up or down, depending on

the situation).

Loading...

Loading...