Testing and calibration of stable installations

Warning :The setting of this section are reserved for authorized persons formed because

they might call into question the reliability of detection.

The site responsible is required to establish security procedures on its site. OLDHAM may be not

responsible for their implementation.

Gas detectors are above all safety instruments. In consideration of this, OLDHAM recommends

regular planned testing of fixed gas detection installations.

A functional test involves injecting a sufficient concentration of gas at the sensor level to trigger pre-

set alarms. This test does not replace a full sensor calibration under any circumstances.

The frequency of gas tests depends on the industrial application in which the detector is in use.

Frequent inspections should be made in the months following the commissioning of the installation,

and then become more widely spaced provided that no significant deviation is observed.

If a detector should fail to react when in contact with the gas, calibration is essential. The frequency

of calibrations is a function of the results of the tests (humidity, temperature, dust, etc.). However, it

must not exceed one year. It is also advisable to calibrate the sensor after exposure to high

concentrations of gas.

. Gas concentration which must be used during manual or semi automatic calibration

- CPS 10 CH4 = 2.5% CH4/air

- CPS 10 H2 = 2% H2/air

- CPS 10 C4H10 = 0.9% C4H10/air

- CPS 10 CO = 100ppm

- CPS 10 NO = 50ppm

- CPS 10 NO

2

= 10ppm

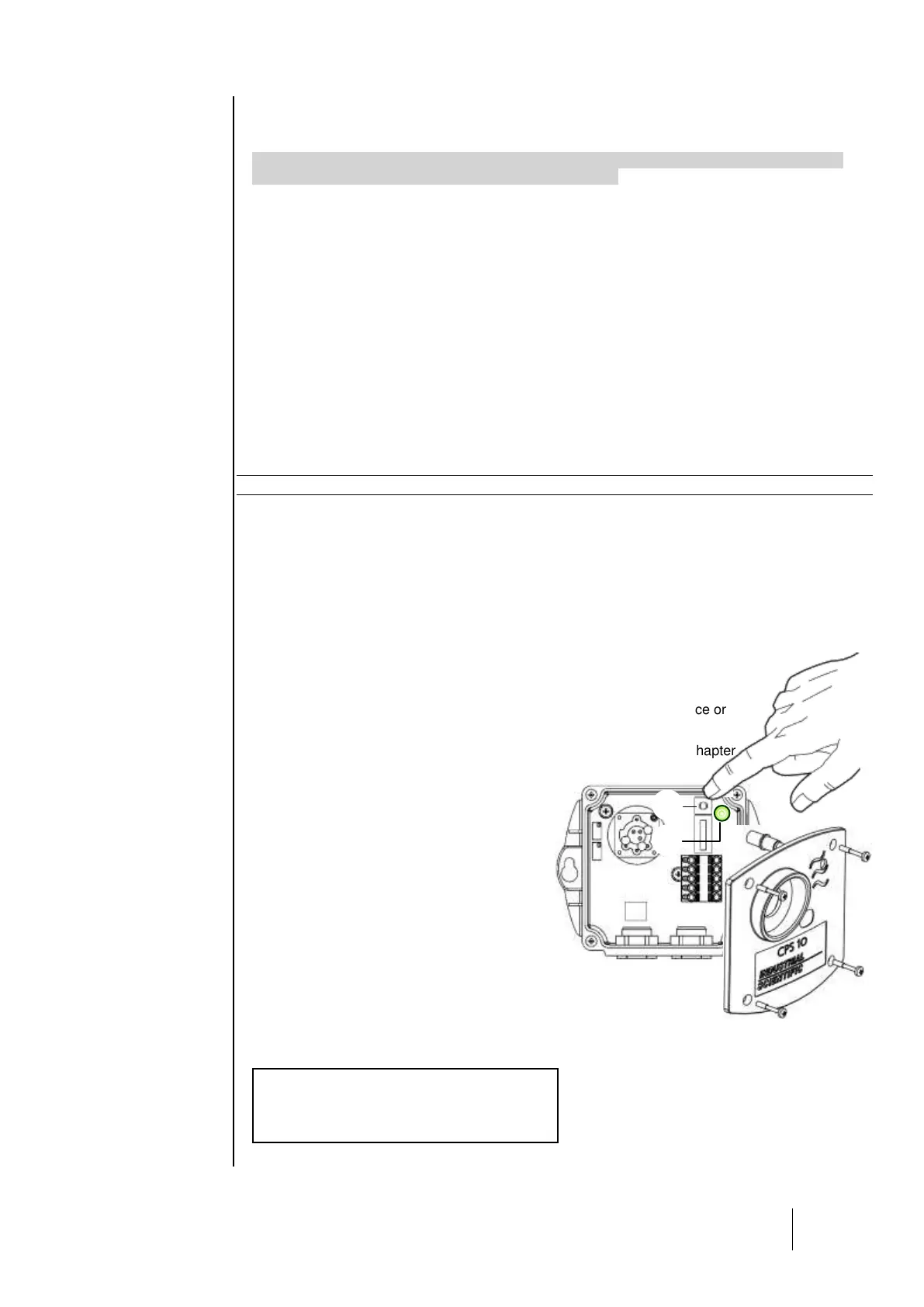

Sensor replacement

Sensors should be replaced as a part of regular preventative maintenance or

following a failed calibration test.

After replacing a sensor, a calibration test must be conducted (see the chapter

on semi-automatic calibration).

To replace a sensor:

- Remove the sensor cover.

- Hold down the sensor replacement button

(1) for 5 seconds, until the solid green

LED (2) is on.

- Release the button.

- Replace the sensor and conduct a

calibration test (mandatory) according to the

semi-automatic procedure.

On the central controller, the “maintenance key” pictogram indicates

that the sensor has been replaced. The key will remain on screen until the

sensor has been calibrated or until the sensor’s power supply fails.

The wear settings for the sensor are initialized upon calibration

Loading...

Loading...