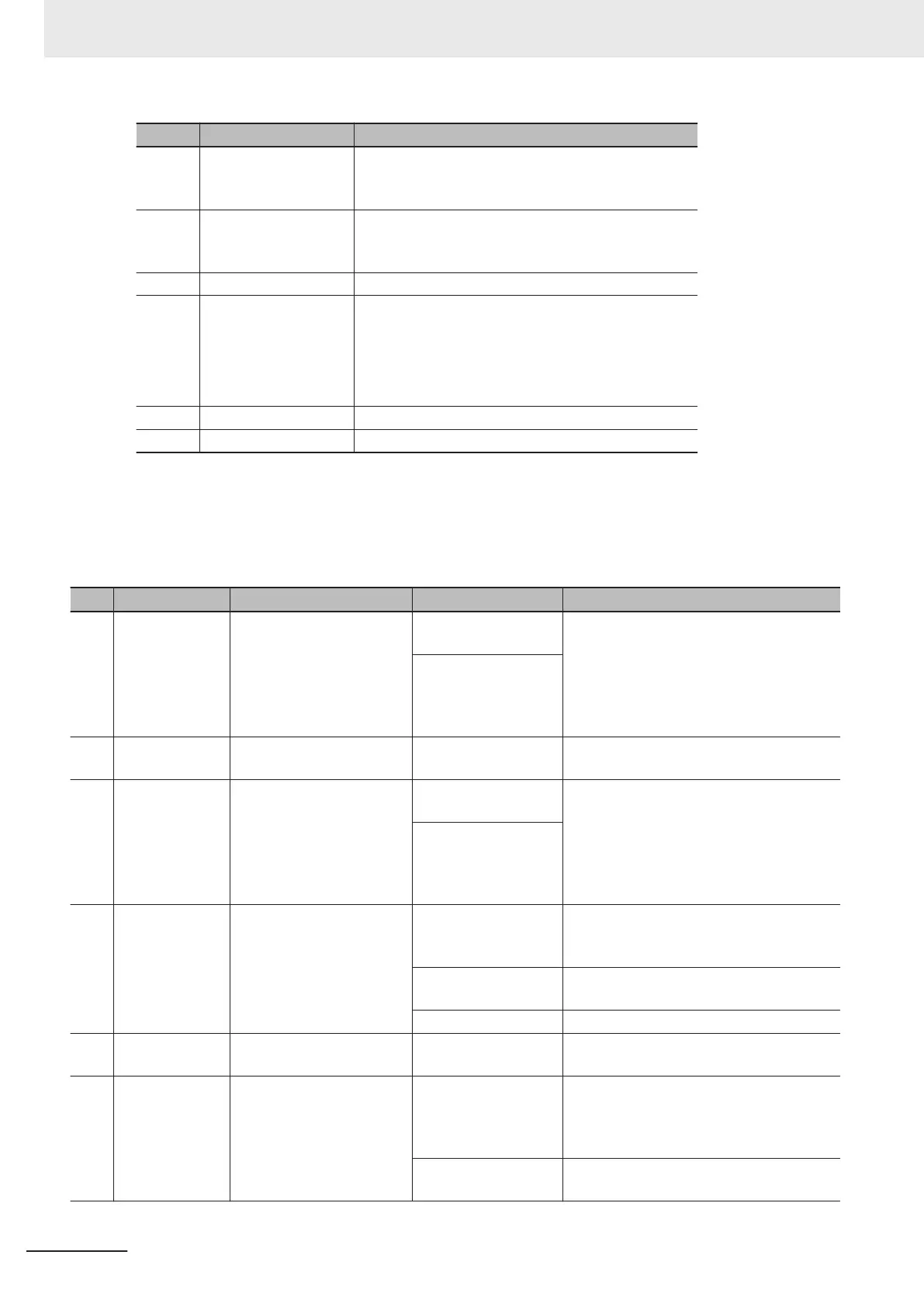

Bit Name Function

31 Timeout error Shows the status of the timeout error.

0: No error

1: Timeout error

30

CRC error Shows the status of the CRC error.

0: No error

1: CRC error

29 to 24 Reserve

23 to 8 Additional data Data to be displayed varies with the Command Code.

• For Command Code = $00D8

Shows the error code.

*1

• For Command Code = $0000, $0040, or $0044

Shows the status.

*2

7 Reserve

0 to 6 Multi-turn position data Upper 7 bits of multi-turn position data

*1. Check the error code and take appropriate measures.

For solutions, refer to Solutions to Error Codes on page A-30 below

.

After you implement measures, cycle the power supply or clear status.

*2. Status represents the information that summarizes error codes. For details, refer to Status on page A-31.

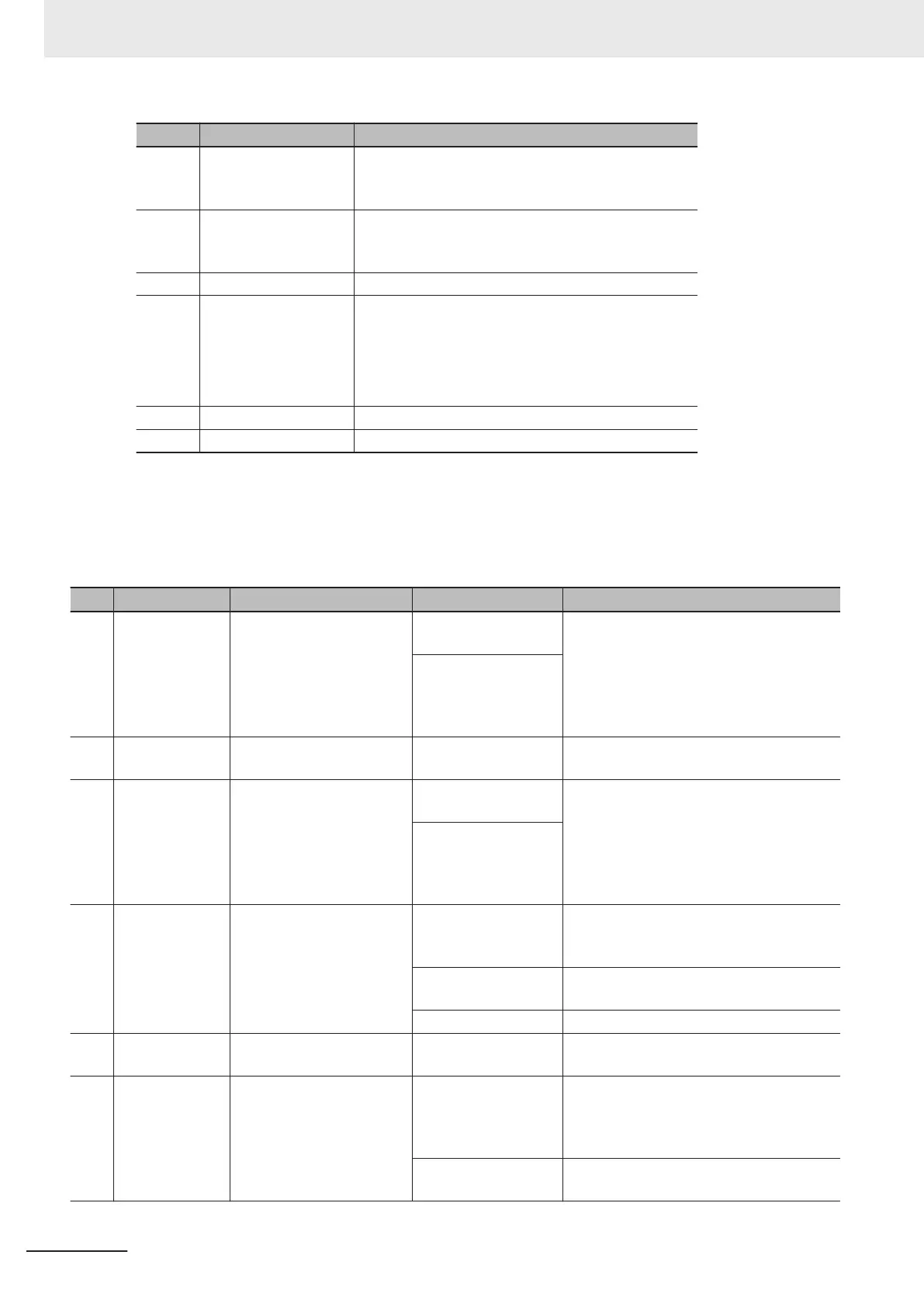

Solutions to Error Codes

Bit Name Function Cause Corrective action

15 Counter code

error

The encoder detected a

one-rotation counter error

.

Excess noise has oc-

curred.

Implement noise countermeasures.

If the error occurs even after the noise

countermeasures are implemented, re-

place the motor because the Servomotor

failed.

Failure due to vibra-

tion, shock, conden-

sation, foreign materi-

al, etc.

1

1 to

14

Reserve

10 Counter incre-

ment error

The encoder detected a

one-rotation counter error

.

Excess noise has oc-

curred.

Implement noise countermeasures.

If the error occurs even after the noise

countermeasures are implemented, re-

place the motor because the Servomotor

failed.

Failure due to vibra-

tion, shock, conden-

sation, foreign materi-

al, etc.

9

Motor overheat

error

The encoder detected the

temperature that exceeded

the protection level of mo-

tor.

The temperature is

high around the mo-

tor.

Adjust the temperature around the motor

to within the operating temperature range.

The motor is over-

loaded

Adjust the motor load rate to within the

specified range.

Encoder failure

If the error persists, replace the motor.

7 to

8

Maintenance in-

formation

This is not used.

6 Absolute posi-

tion detection

error

The encoder detected a

multi-rotation counter error

.

An error was detected

in the multi-rotation

detecting area of the

encoder

After cycling the power supply

, clear multi-

turn.

Excess noise has oc-

curred.

Implement noise countermeasures.

If the error persists, replace the motor.

Appendices

A-30

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

Loading...

Loading...